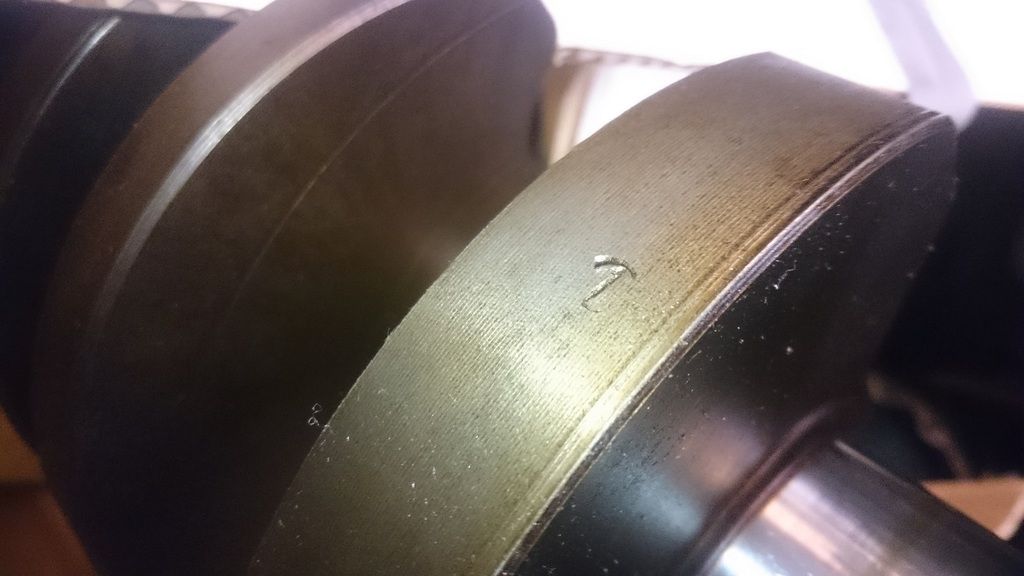

The crank number is a casting number not a part number. Same casting # can be used on different motors. When they recondition a rod big end, they mic it for roundness. If its out of round, they dont bore it out oversized, they grind a little off the caps parting line and when they put it back together, its factory wide on the ends, and a little short in the caps middle, then they torque it and then hone it out again (material is taken from the Id of the cap) to factory spec. Now its spec round again and the rod didnt change working length, but its a a few thou shorter overall. Undersized bearings are physically thicker but have the same OD as stock.