Thanks was not sure. Those springs suck to put on. I use a headlight spring tool, about the only thing that works.!966 225 in the book. I see the casting date is 5/15/64. They used that casting for many years. Ya those springs are goofy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stop in for a cup of coffee

- Thread starter toolmanmike

- Start date

-

Unconventional

Well-Known Member

For good reason rather than these

Dam Chris I would say you got lucky.

zkx14

Duster De-ruster

Never used them..I torque wheel nuts to 'one small grunt' with my 1/2" breaker bar.Those torque limiting sockets actually work pretty good

I still prefer hand torquing, but was impressed when we checked after trying them at a shop I used to use.

Good morning!

Sold a lot of them. They are fairly accurate and consistent.Those torque limiting sockets actually work pretty good

I still prefer hand torquing, but was impressed when we checked after trying them at a shop I used to use.

Good morning!

I don't see how, its been 5 months, I rotated them in July before Carlisle. Torqued them with a torque wrench to 90 ft lbs.Ruh Row! Over torque.

yeah, no kiddingREALLY lucky. THat last one couldn't have lasted long on its own. Just that and the centering on hub...

Good Morning ALL

I don't use either of those

I suppose soDam Chris I would say you got lucky.

God morgen everybody (good morning in Norwegian)

I don't see how, its been 5 months, I rotated them in July before Carlisle. Torqued them with a torque wrench to 90 ft lb

I don't see how, its been 5 months, I rotated them in July before Carlisle. Torqued them with a torque wrench to 90 ft lbs.

yeah, no kidding

I don't use either of those

I suppose so

Oh man, you were being lucky there. I have never used a torque wrench on wheel nuts in my entire life until now in the US. I wonder if I shall go back to manual tightening again.

Unconventional

Well-Known Member

I still have the old star wrench I used as a kid  One arm of it is painted sublime/Euclid green for the right socket on the desert racer

One arm of it is painted sublime/Euclid green for the right socket on the desert racer

One arm of it is painted sublime/Euclid green for the right socket on the desert racer

One arm of it is painted sublime/Euclid green for the right socket on the desert racer

zkx14

Duster De-ruster

I have an air impact, but not really enough air to drive it. So, rarely even bother with it. I was surprised how much torque the battery powered impacts can put out. We had an older Dewalt at work that was 'OK'. Then this past Spring we got another one. The new one kicks ***! The main thing we use it for is the couplers on our vacuum tube system. They are sleeves that wrap around the 2 pipes and pulled tight with 5/8 carriage bolts and nuts. A few weeks ago I was taking one off and accidently bumped the drill to tighten. Only took a few hits and the head popped right off a carriage bolt.. I also borrowed it for a junkyard run a while back and it took a bunch of wheels and suspension fasteners off with no problem. I don't trust them for tightening.

yep, just went and pulled the owners manual, says 85-125 ft lbs.

yeah, I started doing it YEARS ago. It started with the tractors. if you go until they are snug with a lug wrench, you wont have them tight enough and they'll back out. Plus when I had my CDL, that was one part of the state test, you had to show the lugs were torqued and put a marker, usually paint to show the lug hadn't moved to pass IDOT inspections.Oh man, you were being lucky there. I have never used a torque wrench on wheel nuts in my entire life until now in the US. I wonder if I shall go back to manual tightening again.

my roybi will destroy lug nuts and bolts. Thing has 375 ft lbs. I've got a 3/4 in air one that is an old Cromwell, 750 ft lbs.I have an air impact, but not really enough air to drive it. So, rarely even bother with it. I was surprised how much torque the battery powered impacts can put out. We had an older Dewalt at work that was 'OK'. Then this past Spring we got another one. The new one kicks ***! The main thing we use it for is the couplers on our vacuum tube system. They are sleeves that wrap around the 2 pipes and pulled tight with 5/8 carriage bolts and nuts. A few weeks ago I was taking one off and accidently bumped the drill to tighten. Only took a few hits and the head popped right off a carriage bolt.. I also borrowed it for a junkyard run a while back and it took a bunch of wheels and suspension fasteners off with no problem. I don't trust them for tightening.

zkx14

Duster De-ruster

I think a lot tell you 90-100, but just found this on Tire Racks site.

*If you cannot find the vehicle manufacturer's recommended torque spec, you can use the following as a guide.

Hardware Bolt or Stud Size Typical Torque Range in Ft/Lbs

12 x 1.5 mm 70 - 80

12 x 1.25 mm 70 - 80

14 x 1.5 mm 85 - 90

14 x 1.25 mm 85 - 90

7/16 in. 70 - 80

1/2 in. 75 - 85

9/16 in. 135 - 145

*If you cannot find the vehicle manufacturer's recommended torque spec, you can use the following as a guide.

Hardware Bolt or Stud Size Typical Torque Range in Ft/Lbs

12 x 1.5 mm 70 - 80

12 x 1.25 mm 70 - 80

14 x 1.5 mm 85 - 90

14 x 1.25 mm 85 - 90

7/16 in. 70 - 80

1/2 in. 75 - 85

9/16 in. 135 - 145

thanksI think a lot tell you 90-100, but just found this on Tire Racks site.

*If you cannot find the vehicle manufacturer's recommended torque spec, you can use the following as a guide.

Hardware Bolt or Stud Size Typical Torque Range in Ft/Lbs

12 x 1.5 mm 70 - 80

12 x 1.25 mm 70 - 80

14 x 1.5 mm 85 - 90

14 x 1.25 mm 85 - 90

7/16 in. 70 - 80

1/2 in. 75 - 85

9/16 in. 135 - 145

Mattax

Just the facts, ma'am

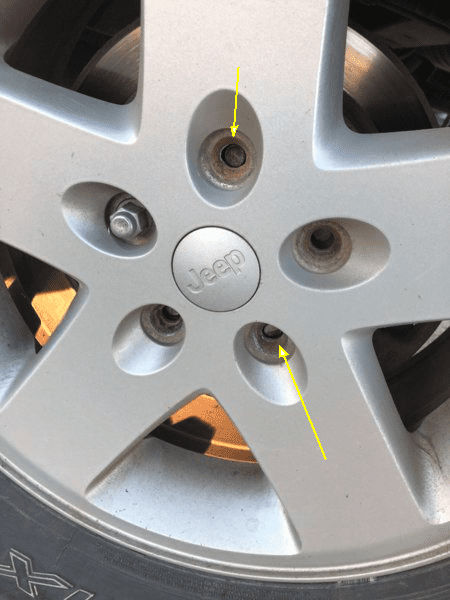

In the photo it looks like the break at 12:00 is oxidized, as is the one at 3:30.

But the one at 5:00 is half bright - maybe the last one to let go? Take a close look, an over torqued should show some necking down and twisting.

Where did those wheel studs come from?

But the one at 5:00 is half bright - maybe the last one to let go? Take a close look, an over torqued should show some necking down and twisting.

Where did those wheel studs come from?

- Joined

- Mar 17, 2018

- Messages

- 17,128

- Reaction score

- 41,821

Mattax

Just the facts, ma'am

6 Lug on the Grand?Wagoneers are 75.7/16 in. 70 - 80

5 Lug on the Mopar A-bodies are 55.

Miught have somehting to do with the yield on the rims, but I use 55 on the bannanaruda

zkx14

Duster De-ruster

Well, they came from inside the wheel, Silly!In the photo it looks like the break at 12:00 is oxidized, as is the one at 3:30.

But the one at 5:00 is half bright - maybe the last one to let go? Take a close look, an over torqued should show some necking down and twisting.

View attachment 1715412699

Where did those wheel studs come from?

Mattax

Just the facts, ma'am

Seemingly random change in thread discussion? I've never done that.And now for something totally unrelated

Mattax

Just the facts, ma'am

next your going to tell me half of them ended up on the side of the road.Well, they came from inside the wheel, Silly!

probably right.

zkx14

Duster De-ruster

That depends which wheel this is. Not sure if he said.next your going to tell me half of them ended up on the side of the road.

probably right.

zkx14

Duster De-ruster

No such thing as random in this threadSeemingly random change in thread discussion? I've never done that.

Mattax

Just the facts, ma'am

In other words, chaos is in control?No such thing as random in this thread

-

Similar threads

- Replies

- 9

- Views

- 647

- Replies

- 8

- Views

- 716