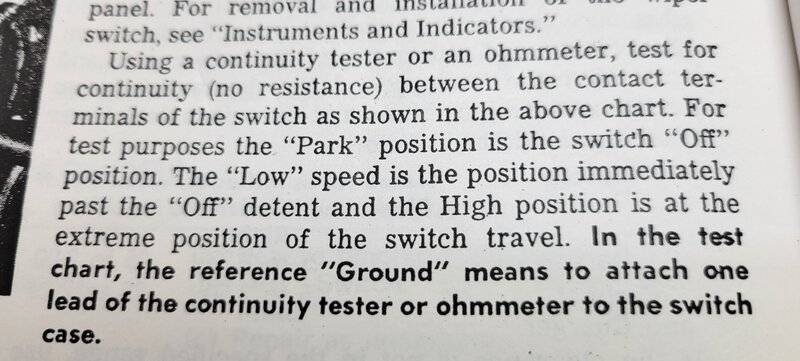

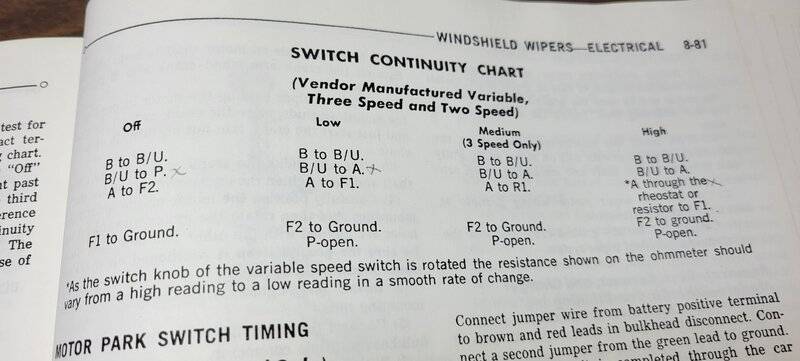

I'm trying to test the wiper switch for the '68 Dart variable speed wiper motor. Pictured are the instrucstions from the shop manual. As I understand "continuity", a "0" reading on the ohmmeter indicates no continuity, i.e. no connection between the two points. A positive reading of any magnitude on the ohmmeter would indicate that a connection over which a current could flow exists between the two points.

If the above stipulation is correct, is the chart from the manual telling me that with the switch in the various positions, i.e. "off", "low", "high", the probe between the named points should read "0"? Likewise, if I get a positive resitance of any magnitude between any of the designated points, it would indicate a bad switch for that position?

If the above stipulation is correct, is the chart from the manual telling me that with the switch in the various positions, i.e. "off", "low", "high", the probe between the named points should read "0"? Likewise, if I get a positive resitance of any magnitude between any of the designated points, it would indicate a bad switch for that position?