You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TF & Speedmaster Flow Tests

- Thread starter Earlie A

- Start date

-

How would you propose they devise a test to show what you get for the added expense of the cnc ported head?

Just as with flow tests, if the tests aren’t conducted back to back, it’s not truly an apples to apples test.

I think we have track results that show what a TrickFlow heads are capable of. @-Boosted- and @73smallblock both have solid 10 second non lightweight dusters. And both of those combo’s have room to grow. @-Boosted- ran 10’s first time out with a new car and new engine and at Vegas. I think that’s better than dyno results. I’m sure there are a few Edelbrock and Speedmaster ET slips floating area. Trouble is both of the examples I gave above although newer have some good pieces in them.

73smallblock

Well-Known Member

I have ran as cast speedmaster heads prior to having trickflow heads. The only thing that changed when I changed the heads was the carburetor. The best the speedmaster's had gone was 11.35 1/4 and I think 7.07 1/8th. The best I have gone with the trickflows is 10.68 1/4 and 6.65 1/8th. It is worth mentioning that I am on the rev limiter at 7000 in the 1/4 a little after 1000'. There is nothing exotic about my combo, everything can be ordered directly from summit except for the intake (Mopar m1). The cam is only a .590 purple shaft and I have never even touched the carburetor. And I'm probably a little light on the the timing at 34*. I feel that I am not even close to pushing my combo.

lead69

hopeless car junkie

In this case I don't think track times are better than dyno results, too many variables. Take one engine, one dyno, two sets of heads and get the tune spot on is the most accurate comparison you can get.I think we have track results that show what a TrickFlow heads are capable of. @-Boosted- and @73smallblock both have solid 10 second non lightweight dusters. And both of those combo’s have room to grow. @-Boosted- ran 10’s first time out with a new car and new engine and at Vegas. I think that’s better than dyno results. I’m sure there are a few Edelbrock and Speedmaster ET slips floating area. Trouble is both of the examples I gave above although newer have some good pieces in them.

lead69

hopeless car junkie

I have an engine, a dyno, two out of the three sets of heads I want to test and two out of the three intakes so I am getting close.I’m surprised that by now there have been no reported dyno shoot-outs between the TF’s and some of the other offerings.

Like when EM did the test between stock/stealth/Ede/TF240’s.

You could do stock, SM, Ede, TF190.

Only, instead of using a basically stock short block, use something like a 10-10.5:1 stroker with a decent sized cam in it, and an intake/carb that would keep up.

Fundamentally I’m a fan of the TF190, but I’ve never used them on anything myself.

I don’t look at them as an alternative to an offset rocker race oriented head.

If they made 575hp, straight ootb, on a pretty basic(although somewhat rowdy) combo……I’d say they are doing what I’d expect out of them.

Certainly, that level of performance is achievable out of reworked Ede/SM heads, but that route requires more effort from the end user than selecting “add to cart” from summit’s site.

Are there any track results that show what your ported Speedmasters are capable of.I think we have track results that show what a TrickFlow heads are capable of. @-Boosted- and @73smallblock both have solid 10 second non lightweight dusters. And both of those combo’s have room to grow. @-Boosted- ran 10’s first time out with a new car and new engine and at Vegas. I think that’s better than dyno results. I’m sure there are a few Edelbrock and Speedmaster ET slips floating area. Trouble is both of the examples I gave above although newer have some good pieces in them.

-Boosted-

Hard Member

All of the recent passes he made are with his heads. Very capable which is why I want a set. I'm just playing with the Trick Flows until I get a set from him.Are there any track results that show what your ported Speedmasters are capable of.

That's news to me, I was under the assumption he's running Edelbrock's currently and Indy 360-1 in the past.All of the recent passes he made are with his heads.

That's news to me, I was under the assumption he's running Edelbrock's currently and Indy 360-1 in the past.

You gotta know by know a Speedmaster and Edelbrock sleep in the same bed. I’m running an old 350.00 set of repaired open chamber 340 style heads. That were ported around 2008 and have an old Neway hand cut 3 angle valve job.

-Boosted-

Hard Member

Yeah, I meant the eddies which I keep hearing are pretty much the same.That's news to me, I was under the assumption he's running Edelbrock's currently and Indy 360-1 in the past.

Earlie A

Well-Known Member

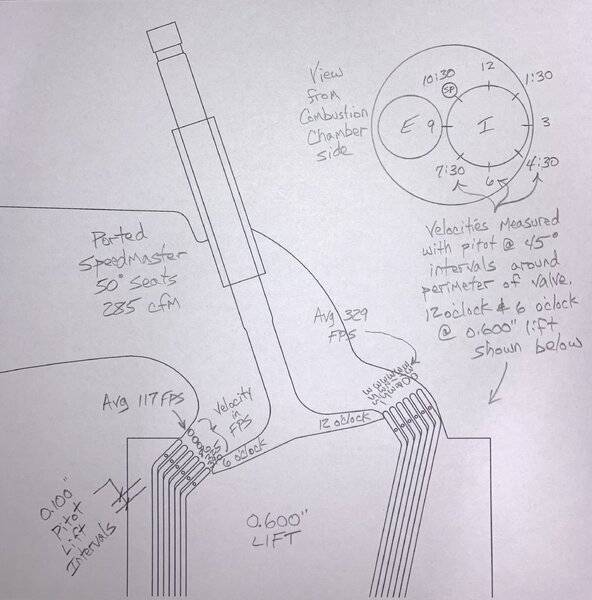

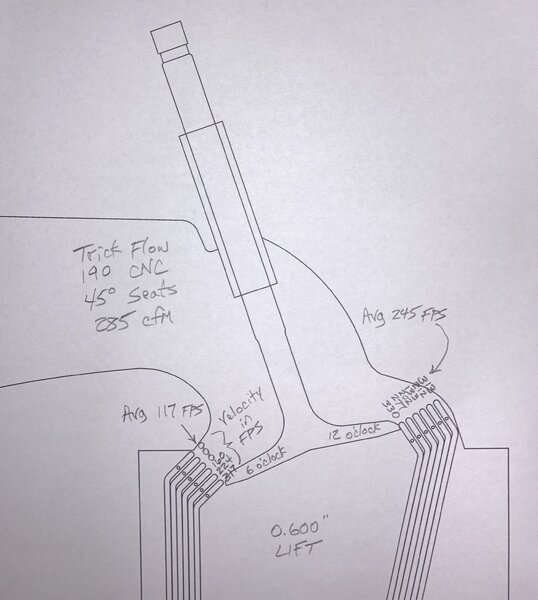

Here's a snapshot of the velocities around the intake valve measured from the combustion chamber side at 0.600 lift in both the Speedmaster ported head and the Trick Flow 190 CNC head. For me, the 6 o'clock (short side of port) and 12 o'clock (long side of port) positions were most interesting.

I thought the 6 position in the TF would be much better than the SM. There is no significant difference between the two. As can be seen, the flow is separating from the short side and probably even rolling/reversing direction in both ports.

In both heads the 10:30 position (results not shown) is the strongest flowing, as it should be. The 9 o'clock and 12 o'clock positions should be the next strongest. Not at 12 o'clock in the TF. The 12 position shows the result of the crisscrossing flow in the TF port. The velocity next to the valve seat (313) and the valve face (330) are still pretty good, but they go quite low in between.

I'm not showing this to bash the TF. I'm showing it because of the surprising results and the prior discussions about the purpose of the vein in the TF port. There are areas where the TF was a little better than the SM.

I thought the 6 position in the TF would be much better than the SM. There is no significant difference between the two. As can be seen, the flow is separating from the short side and probably even rolling/reversing direction in both ports.

In both heads the 10:30 position (results not shown) is the strongest flowing, as it should be. The 9 o'clock and 12 o'clock positions should be the next strongest. Not at 12 o'clock in the TF. The 12 position shows the result of the crisscrossing flow in the TF port. The velocity next to the valve seat (313) and the valve face (330) are still pretty good, but they go quite low in between.

I'm not showing this to bash the TF. I'm showing it because of the surprising results and the prior discussions about the purpose of the vein in the TF port. There are areas where the TF was a little better than the SM.

-Boosted-

Hard Member

@Earlie A , I am thankful for people like you (and others) that take the time to do research, experiment, test and then share what you have learned with the rest of us. I don’t have the patience, resources or knowledge to do this kind of stuff myself but appreciate the fact that I can use this information to to figure out what I want to do with my combo.

Send me a message with your address and t-shirt size. I’m going to make you a custom, one of a kind t-shirt that would be perfect for what you do and share here.

Send me a message with your address and t-shirt size. I’m going to make you a custom, one of a kind t-shirt that would be perfect for what you do and share here.

PRH

Well-Known Member

I wonder if……..

One were to rework one of the SM ports to a lesser extent than what’s been tested so far, concentrating primarily on getting SSR area sorted out so that it would allow the flow to show increases past .600 lift…….even if the flow capacity at those lifts is below the current 285cfm level.

Say you got 270-275@.650-.700……….would the flow in the areas(6 o’clock, etc) where it’s next to nothing now……..still be next to nothing?

At the other end of the spectrum, I wonder how one of PBR’s non-stalling 300+ cfm SM’s would compare with that test.

One were to rework one of the SM ports to a lesser extent than what’s been tested so far, concentrating primarily on getting SSR area sorted out so that it would allow the flow to show increases past .600 lift…….even if the flow capacity at those lifts is below the current 285cfm level.

Say you got 270-275@.650-.700……….would the flow in the areas(6 o’clock, etc) where it’s next to nothing now……..still be next to nothing?

At the other end of the spectrum, I wonder how one of PBR’s non-stalling 300+ cfm SM’s would compare with that test.

Earlie A

Well-Known Member

That's very kind. The world needs more encouragers like you.@Earlie A , I am thankful for people like you (and others) that take the time to do research, experiment, test and then share what you have learned with the rest of us. I don’t have the patience, resources or knowledge to do this kind of stuff myself but appreciate the fact that I can use this information to to figure out what I want to do with my combo.

Send me a message with your address and t-shirt size. I’m going to make you a custom, one of a kind t-shirt that would be perfect for what you do and share here.

Earlie A

Well-Known Member

Without increasing the size of the valve, any major gains would have to come from areas like 1:30, 3, 4:30, 6, 7:30. 10:30 is maxed out, 12 and 9 are pretty busy as well. David Vizard talks a lot about leaning/biasing the port for more flow at high lift. Seems to me that is just trying to push more air through the 10:30 position, which is already doing the lion's share of the work.I wonder if……..

One were to rework one of the SM ports to a lesser extent than what’s been tested so far, concentrating primarily on getting SSR area sorted out so that it would allow the flow to show increases past .600 lift…….even if the flow capacity at those lifts is below the current 285cfm level.

Say you got 270-275@.650-.700……….would the flow in the areas(6 o’clock, etc) where it’s next to nothing now……..still be next to nothing?

At the other end of the spectrum, I wonder how one of PBR’s non-stalling 300+ cfm SM’s would compare with that test.

So, I think you are correct that the key is areas like 4:30, 6 and 7:30 if the SSR can be fixed, and areas like 1:30, 3 and 4:30 if shrouding can be reduced. I certainly have not figured out the SSR but I am trying to figure out a system to measure what is going on. There's an old saying in process control "If you can measure it, you can manage it".

I'm chuckling that you place my SSR on one end of the spectrum and PBR's on the other. You are correct. No offense taken. We are blessed to have him around.

Earlie A

Well-Known Member

There is a relationship between velocity and turn radius. Starting slow like you suggest may be the key to figuring it out.I wonder if……..

One were to rework one of the SM ports to a lesser extent than what’s been tested so far, concentrating primarily on getting SSR area sorted out so that it would allow the flow to show increases past .600 lift…….even if the flow capacity at those lifts is below the current 285cfm level.

Say you got 270-275@.650-.700……….would the flow in the areas(6 o’clock, etc) where it’s next to nothing now……..still be next to nothing?

At the other end of the spectrum, I wonder how one of PBR’s non-stalling 300+ cfm SM’s would compare with that test.

PRH

Well-Known Member

My suspicion is, especially when working with a low port head that doesn’t have a lot of height at the SSR, that even ports that seem to have a form that allows the flow to stay connected to the floor(no real obvious change in sound, and flows not backing up), that they still end up having areas of the valve perimeter that “go dead” at a certain lift.

But, you have to get a port form that “seems” to be good first(like one of PBR’s non-stalling ports)………then the seat velocity test would tell the tale.

With your current heads, at what lift do you see the dead areas start to show up?

But, you have to get a port form that “seems” to be good first(like one of PBR’s non-stalling ports)………then the seat velocity test would tell the tale.

With your current heads, at what lift do you see the dead areas start to show up?

Pittsburghracer is really struggling right now. With two customers dictating head gasket bore sizes I lost my consistency. At first I blamed it on heads that had already been worked on. Then a very small head gasket size on an already limited Edelbrock chamber. And now issues on a set of Speedmaster heads with a bigger but limited chamber size. Lack of parts for both those heads and a paycheck yet this porting season has me in a hoooo hummm mood. So with an extremely busy outside the shop week I’m going to set both those sets of heads aside and grab another head and do it how I usually do it as a confidence builder. I’m tired of working twice as hard and making nothing. No more small chamber heads for this guy. Find someone else.

PRH

Well-Known Member

If the customer dictates a smaller chamber, and that affects the final flow numbers, then ……… “iiwii”.

If the customer dictates a smaller chamber, and that affects the final flow numbers, then ……… “iiwii”.

Just hard for me to do.

Earlie A

Well-Known Member

This attachment might be hard to see. All is good at 0.200, there are signs at 0.300, the first zero shows up at 0.400.My suspicion is, especially when working with a low port head that doesn’t have a lot of height at the SSR, that even ports that seem to have a form that allows the flow to stay connected to the floor(no real obvious change in sound, and flows not backing up), that they still end up having areas of the valve perimeter that “go dead” at a certain lift.

But, you have to get a port form that “seems” to be good first(like one of PBR’s non-stalling ports)………then the seat velocity test would tell the tale.

With your current heads, at what lift do you see the dead areas start to show up?

Across the top of the second attachment are the corresponding port velocities at the apex for the different valve lifts. The second attachment shows the port and chamber looking down from above, so the 3 oclock and 9 oclock positions are opposite of the drawings in the earlier posts.

Last edited:

PRH

Well-Known Member

That last data is for the SM head or the TF head?

Without having that seat velocity map to go by, at what lift did other indicators present that something wasn’t happy?

At .400…….. or after that?

Without having that seat velocity map to go by, at what lift did other indicators present that something wasn’t happy?

At .400…….. or after that?

Earlie A

Well-Known Member

The last post is all SM. There are some very small fluctuations in the depression around 0.400, a little more at 0.500, but the port is still quite stable up to 0.550-0.600. Even at 0.600, the depression only climbs about 0.5" but doesn't bounce much. Noise starts building around 0.400-0.500 as well, but it's a consistent noise - no gulping, slurping and bouncing. The TF on the other hand does the gulp, slurp and bounce thing.That last data is for the SM head or the TF head?

Without having that seat velocity map to go by, at what lift did other indicators present that something wasn’t happy?

At .400…….. or after that?

PRH

Well-Known Member

I missed this earlier:

I’d say the change in sound you hear at .400 up is the signal “something” isn’t as happy as it was before the sound changed.

Fwiw, that’s pretty much par for the course on any standard port SBM head I’ve ever tested.

What I meant was any port form that has some obvious separation issues vs one that doesn’t.I'm chuckling that you place my SSR on one end of the spectrum and PBR's on the other. You are correct. No offense taken. We are blessed to have him around.

I’d say the change in sound you hear at .400 up is the signal “something” isn’t as happy as it was before the sound changed.

Fwiw, that’s pretty much par for the course on any standard port SBM head I’ve ever tested.

Last edited:

-

Similar threads

- Replies

- 57

- Views

- 4K