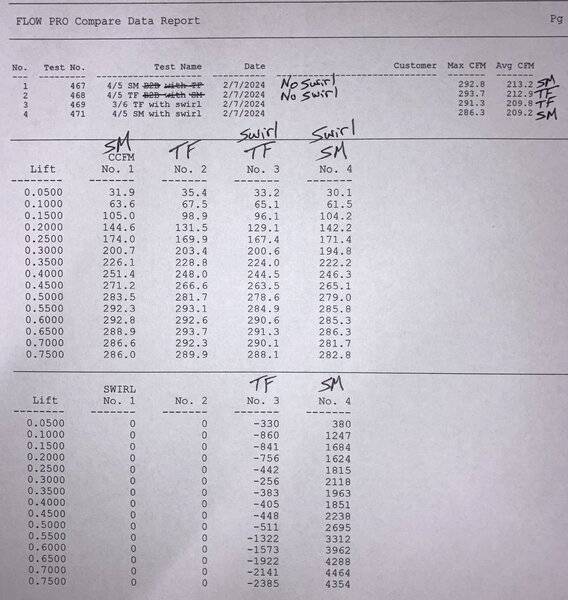

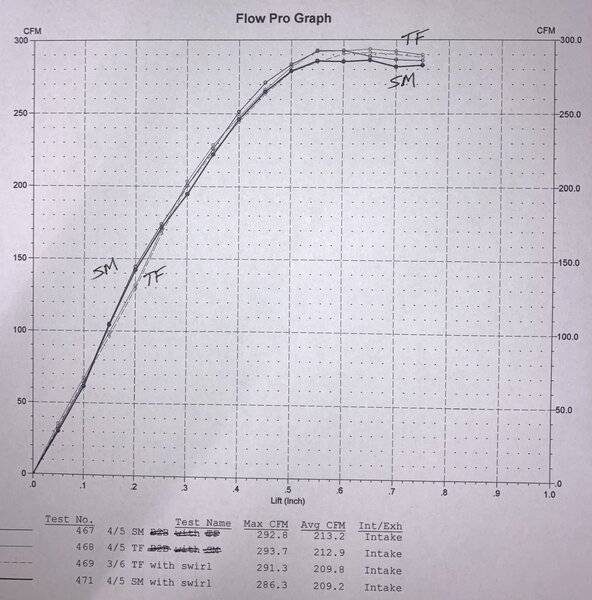

Here's back to back tests of a stock SBM OOTB Trick Flow 190cc CNC port and a non-professionally hand ported Speedmaster 186cc port. TF has stock 45 deg valve angle. SM has 50 deg valve angle with valves sunk 0.090". No swirl meter on the first two tests. Swirl meter was used for the last two tests. One port is a right hand port, the other is a left hand port, which changes the swirl direction. The swirl meter reduces flow because of the slight resistance added by the meter.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TF & Speedmaster Flow Tests

- Thread starter Earlie A

- Start date

-

Have you only checked one port on the TrickFlow heads so far.

Yes. Do you find much variation on CNC ports?Have you only checked one port on the TrickFlow heads so far.

Yes. Do you find much variation on CNC ports?

Yes I did. One flowed almost exactly what they said it would (301). One port flowed 285 and sounded like I flipped on the garbage disposal and fell on its face. I was try to flow an intake i

Ported for a customer so I tried another port and it stalled at 290 and backed up slightly. I flow tested his intake on that port and it really hurt the flow on the intake. I kinda thought I knew what the problem was so two weeks later I spent 1 minutes on the 290 port and it flowed over 300 on its next test.

This makes me cry over what I paid for, and have in, my super commando heads. $$$$

I’ll test the others. There was a little more noise and instability than I was expecting, but I guess all the twisting and turning in the bowl plays into that. Swirl in the TF was reduced substantially over the SM. I’ll eventually try to clean them up a little.Yes I did. One flowed almost exactly what they said it would (301). One port flowed 285 and sounded like I flipped on the garbage disposal and fell on its face. I was try to flow an intake i

Ported for a customer so I tried another port and it stalled at 290 and backed up slightly. I flow tested his intake on that port and it really hurt the flow on the intake. I kinda thought I knew what the problem was so two weeks later I spent 1 minutes on the 290 port and it flowed over 300 on its next test.

Yes. Do you find much variation on CNC ports?

@-Boosted- sent me this today and honestly I forgot all about this post. It sure doesn’t make the TrickFlow heads look very good either.

Trick Flow sb heads

Are the Super Commando heads a rebranded Edelbrock head?This makes me cry over what I paid for, and have in, my super commando heads. $$$$

360duster

Well-Known Member

don´t think so. It was an option from mopar (P4876310 for example) a while back with offset Intake rockers....not very popular.

Michael

Michael

Here's the flow data for all 4 ports in one TF head.

View attachment 1716204527

View attachment 1716204528

So what are your thoughts on this

Similar. huge, relocated intake valve. takes a offset rocker. But yes, cast by edelbrock.Are the Super Commando heads a rebranded Edelbrock head?

Similar. huge, relocated intake valve. takes a offset rocker. But yes, cast by edelbrock.

What kind of numbers are you getting out of those heads and what does it run at the track.

it runs 10.20's with a full interior, 3.91 gear, in a 10x 26 inch tire car. I shift at 7400 ish. traps 126-128. our track is notoriously "slow" as the last 1/8 mile is uphill. it's been a great engine. I have dyno sheets with 618HP @7400. before i switched to E85. Heads flowed a best of 290 on a 4.030 bore around 700. the whole downfall of these heads is they (mopar) advertise flow numbers on a R block bore. the valve was a little shrouded on a 4.030. They were just more $ than they were worth, or the extra porting i have into them. Maybe if i had an R block they would shine more. But in the end...could have bought an off the shelf set of RPM's, shipped them off, and got the same 290, without the goofy custom valvetrain.What kind of numbers are you getting out of those heads and what does it run at the track.

it runs 10.20's with a full interior, 3.91 gear, in a 10x 26 inch tire car. I shift at 7400 ish. traps 126-128. our track is notoriously "slow" as the last 1/8 mile is uphill. it's been a great engine. I have dyno sheets with 618HP @7400. before i switched to E85. Heads flowed a best of 290 on a 4.030 bore around 700. the whole downfall of these heads is they (mopar) advertise flow numbers on a R block bore. the valve was a little shrouded on a 4.030. They were just more $ than they were worth, or the extra porting i have into them. Maybe if i had an R block they would shine more. But in the end...could have bought an off the shelf set of RPM's, shipped them off, and got the same 290, without the goofy custom valvetrain.

Still a nice running combo. What’s it weigh and what intake are you running. Just curious on what is the difference shifting at 6800 compared to 7400. I’ve never cranked mine up that high.

Last edited:

Thats where it was done making HP, so thats where i shift it. haha. it will lose some if i short shift it. I used to have a cheetah that i absolutely hated, and would shift early by mistake. Went back to a B&M pro ratchet and never looked back. It probably weights in a tick over 3100 with me in it. my last weight slip was 3100 sitting in it, but that was before wilwood brakes, pulling the wiper motor, race seats, etc. I have a fiberglass front bumper and hood, but rest of the car is steel. I have a super victor. it's port matched also.Still a nice running combo. What’s it weigh and what intake are you running. Just curious on what is the difference shifting at 5800 compared to 7400. I’ve never cranked mine up that high.

Thats where it was done making HP, so thats where i shift it. haha. it will lose some if i short shift it. I used to have a cheetah that i absolutely hated, and would shift early by mistake. Went back to a B&M pro ratchet and never looked back. It probably weights in a tick over 3100 with me in it. my last weight slip was 3100 sitting in it, but that was before wilwood brakes, pulling the wiper motor, race seats, etc. I have a fiberglass front bumper and hood, but rest of the car is steel. I have a super victor. it's port matched also.

I fixed that. I typed 5800 but ment 6800 but you probably knew that.

Thats where it was done making HP, so thats where i shift it. haha. it will lose some if i short shift it. I used to have a cheetah that i absolutely hated, and would shift early by mistake. Went back to a B&M pro ratchet and never looked back. It probably weights in a tick over 3100 with me in it. my last weight slip was 3100 sitting in it, but that was before wilwood brakes, pulling the wiper motor, race seats, etc. I have a fiberglass front bumper and hood, but rest of the car is steel. I have a super victor. it's port matched also.

I’m going to be doing some super Victor testing soon and I’ll post up my findings. I still have mine sitting here too that I quickly ported and threw on my old 408. It ran 9.74 on a worn out block. I may hit it again and loan it to my friend that I’m doing a set of Edelbrock heads for now. He has a stock super Victor but I’d hate to see him run that one.

at one point i had an old M1 that i almost ran, but couldn't convince the spread bore flange (or modifying it for a 4150) was the right thing to do. Is there much out there thats supposed to be better than a Super victor?I’m going to be doing some super Victor testing soon and I’ll post up my findings. I still have mine sitting here too that I quickly ported and threw on my old 408. It ran 9.74 on a worn out block. I may hit it again and loan it to my friend that I’m doing a set of Edelbrock heads for now. He has a stock super Victor but I’d hate to see him run that one.

at one point i had an old M1 that i almost ran, but couldn't convince the spread bore flange (or modifying it for a 4150) was the right thing to do. Is there much out there thats supposed to be better than a Super victor?

I love Victor340’s but I could have sold my super Victor three times and can’t bring myself to do it.

Dartswinger70

Well-Known Member

Im a rookie with a dumb question but how do these compare with stock x or J heads in terms of flow numbers? how much is t be gained going aftermarket? I understand aluminum is easier to port polish and modify etc. I am in a situation now where I have a set of J's with 2.02s that need to be sent out Im figuring 700 is to rebuild but the set as cores are pobably worth 250 so the math is basically 950 and a set of speedmasters are in that ball park. I am thinking if I get the j s redone and dont use them i couldnt get 950 for them...decisions decisions  I also have a set of 1.88 360 Js freshly done...need a boottm end for those.

I also have a set of 1.88 360 Js freshly done...need a boottm end for those.

Last edited:

Here are a few thoughts on a few different fronts.So what are your thoughts on this

If someone is building a high rpm 340/360 or a stout street 408/416 and budget is a consideration, these are a great option out of the box. Maybe the best option for the money. In my opinion ported Edelbrocks or Speedmasters could be just as good, but it takes a lot of work to get them there. The TF has a nice valve job with valves already back cut. The throat size is 89%-90% which leaves a little wiggle room. The fit between the valve and guide is right. The combustion chamber design seems better than the other options. It's a nice head.

With that said, I was a little disappointed with them. That is probably a result of my expectations being too high or misguided from the beginning. I'm not knocking the TF's - these are nice heads. But I was hoping to have an aha moment with the TF that would help me fix the flow issues that I experience on all SBM heads I've played with so far - flow separation and back up above 0.550 or 0.600 lift. But, it seems that TF suffers from the same issues. I'm sure a little clean up work around the guide and in the bowl would help. I suspect there is flow to be gained by working on the head bolt bulge and PRP. It would be interesting to know how 50 degree seats would change things. I'm sure this head can go 300-310 cfm with the 2.02 valve. I also think an Edelbrock/Speedmaster can get there. In the end, it seems the tight push rod pinch, low port, 18 degree valve angle and head bolt locations just create some insurmountable issues. You're not going 350 cfm without major changes.

What I have spent the most time thinking about is the anti-swirl port design. I've become more convinced that the twisted bowl is not about fuel shear and not about increasing cfm. I think it is about reducing swirl. Here's my understanding of swirl. In a production car or a low rpm street car swirl can increase low end torque and reduce emissions. In a performance car swirl starts being counterproductive. It takes energy to swirl the air/fuel mixture, and that energy could have otherwise been used to get more air into the chamber. So, high swirl reduces volumetric efficiency. High swirl can also centrifuge the heavy fuel to the cylinder walls, throwing it out of suspension. That creates fuel washing and rich/lean conditions which can cause poor combustion and even detonation. So it seems the reduction in swirl in the TF heads would be a good thing. But look at how the swirl reduction was acheived. It was by forcing the air to go where it does not want to go, and by making the air/fuel mixture turn more than natural. In my mind these things are not efficient for dry flow, but even more detrimental to wet flow. I'd really like to see A/B dyno and track testing TF against others. Maybe the design is great for power and performance. I really don't know.

PBR, I know you have extensive experience with the Eddy's and at least some with the TF (maybe a lot). What's your opinion of the performance potential of both?

Dartswinger70

Well-Known Member

I have been seeing the speedmasters still need massaging by a machine shop or at leas a check over they arent truly out of the box bolt on well not all of them any way...its easy for someone who has a machine shop but not for all folks out there who dont.

Im a rookie with a dumb question but how do these compare with stock x or J heads in terms of flow numbers? how much is t be gained going aftermarket? I understand aluminum is easier to port polish and modify etc. I am in a situation now where I have a set of J's with 2.02s that need to be sent out Im figuring 700 is to rebuild but the set as cores are pobably worth 250 so the math is basically 950 and a set of speedmasters are in that ball park. I am thinking if I get the j s redone and dont use them i couldnt get 950 for them...decisions decisionsI also have a set of 1.88 360 Js freshly done...need a boottm end for those.

I'm no expert when it comes to putting combinations together, so hopefully some of the other guys will jump in and help with that. My experience with the heads is this - stock x or j with a 2.02 will flow 210-220. Stock j with 1.88 will do 190-195. Stock Speedmaster will flow 250ish. Factory CNC'd Speedmaster (mine were a disaster) flowed 266cfm. The TF is 290-295 on my bench. In my opinion, the TF are as close to bolt on ready as you can buy. The Speedmasters need help from a good machine shop. I'd stay away from the factory CNC'd Speedmasters.I have been seeing the speedmasters still need massaging by a machine shop or at leas a check over they arent truly out of the box bolt on well not all of them any way...its easy for someone who has a machine shop but not for all folks out there who dont.

Here are a few thoughts on a few different fronts.

If someone is building a high rpm 340/360 or a stout street 408/416 and budget is a consideration, these are a great option out of the box. Maybe the best option for the money. In my opinion ported Edelbrocks or Speedmasters could be just as good, but it takes a lot of work to get them there. The TF has a nice valve job with valves already back cut. The throat size is 89%-90% which leaves a little wiggle room. The fit between the valve and guide is right. The combustion chamber design seems better than the other options. It's a nice head.

With that said, I was a little disappointed with them. That is probably a result of my expectations being too high or misguided from the beginning. I'm not knocking the TF's - these are nice heads. But I was hoping to have an aha moment with the TF that would help me fix the flow issues that I experience on all SBM heads I've played with so far - flow separation and back up above 0.550 or 0.600 lift. But, it seems that TF suffers from the same issues. I'm sure a little clean up work around the guide and in the bowl would help. I suspect there is flow to be gained by working on the head bolt bulge and PRP. It would be interesting to know how 50 degree seats would change things. I'm sure this head can go 300-310 cfm with the 2.02 valve. I also think an Edelbrock/Speedmaster can get there. In the end, it seems the tight push rod pinch, low port, 18 degree valve angle and head bolt locations just create some insurmountable issues. You're not going 350 cfm without major changes.

What I have spent the most time thinking about is the anti-swirl port design. I've become more convinced that the twisted bowl is not about fuel shear and not about increasing cfm. I think it is about reducing swirl. Here's my understanding of swirl. In a production car or a low rpm street car swirl can increase low end torque and reduce emissions. In a performance car swirl starts being counterproductive. It takes energy to swirl the air/fuel mixture, and that energy could have otherwise been used to get more air into the chamber. So, high swirl reduces volumetric efficiency. High swirl can also centrifuge the heavy fuel to the cylinder walls, throwing it out of suspension. That creates fuel washing and rich/lean conditions which can cause poor combustion and even detonation. So it seems the reduction in swirl in the TF heads would be a good thing. But look at how the swirl reduction was acheived. It was by forcing the air to go where it does not want to go, and by making the air/fuel mixture turn more than natural. In my mind these things are not efficient for dry flow, but even more detrimental to wet flow. I'd really like to see A/B dyno and track testing TF against others. Maybe the design is great for power and performance. I really don't know.

PBR, I know you have extensive experience with the Eddy's and at least some with the TF (maybe a lot). What's your opinion of the performance potential of both?

Here are a few thoughts on a few different fronts.

If someone is building a high rpm 340/360 or a stout street 408/416 and budget is a consideration, these are a great option out of the box. Maybe the best option for the money. In my opinion ported Edelbrocks or Speedmasters could be just as good, but it takes a lot of work to get them there. The TF has a nice valve job with valves already back cut. The throat size is 89%-90% which leaves a little wiggle room. The fit between the valve and guide is right. The combustion chamber design seems better than the other options. It's a nice head.

With that said, I was a little disappointed with them. That is probably a result of my expectations being too high or misguided from the beginning. I'm not knocking the TF's - these are nice heads. But I was hoping to have an aha moment with the TF that would help me fix the flow issues that I experience on all SBM heads I've played with so far - flow separation and back up above 0.550 or 0.600 lift. But, it seems that TF suffers from the same issues. I'm sure a little clean up work around the guide and in the bowl would help. I suspect there is flow to be gained by working on the head bolt bulge and PRP. It would be interesting to know how 50 degree seats would change things. I'm sure this head can go 300-310 cfm with the 2.02 valve. I also think an Edelbrock/Speedmaster can get there. In the end, it seems the tight push rod pinch, low port, 18 degree valve angle and head bolt locations just create some insurmountable issues. You're not going 350 cfm without major changes.

What I have spent the most time thinking about is the anti-swirl port design. I've become more convinced that the twisted bowl is not about fuel shear and not about increasing cfm. I think it is about reducing swirl. Here's my understanding of swirl. In a production car or a low rpm street car swirl can increase low end torque and reduce emissions. In a performance car swirl starts being counterproductive. It takes energy to swirl the air/fuel mixture, and that energy could have otherwise been used to get more air into the chamber. So, high swirl reduces volumetric efficiency. High swirl can also centrifuge the heavy fuel to the cylinder walls, throwing it out of suspension. That creates fuel washing and rich/lean conditions which can cause poor combustion and even detonation. So it seems the reduction in swirl in the TF heads would be a good thing. But look at how the swirl reduction was acheived. It was by forcing the air to go where it does not want to go, and by making the air/fuel mixture turn more than natural. In my mind these things are not efficient for dry flow, but even more detrimental to wet flow. I'd really like to see A/B dyno and track testing TF against others. Maybe the design is great for power and performance. I really don't know.

PBR, I know you have extensive experience with the Eddy's and at least some with the TF (maybe a lot). What's your opinion of the performance potential of both?

The TrickFlow heads have almost nothing to gain at the pinch with the odd shaped pushrod hole. I used my sonic checker and was getting a strange reading that I didn’t interpret right and went through. I didn’t care as I was going to weld them up and run a .350 offset rocker Harlan Sharp made for me. But of course it’s easier to weld before you get a hole but I got her done. Following TrickFlow for over 10 years of running my fingers through their ports even before they offered any Mopar heads I’m very disappointed finding advertised 300 cfm ports flowing a turbulent 285 or worse. I’ve gotten 343 cfm out of a stock location pushrod Edelbrock head with a 2.08 valve. If you read that link I posted what did he get out of a TrickFlow head with a 2.08 valve??? Something like 308 right. I’ll modify them and make a nice set of heads but in the end I doubt if I’ll ever run them. One of my stupider purchases. One of these Sundays I’ll grab one and throw it on my porting bench and do some quick testing.

Last edited:

-