koryliss

Well-Known Member

Blue Missile,

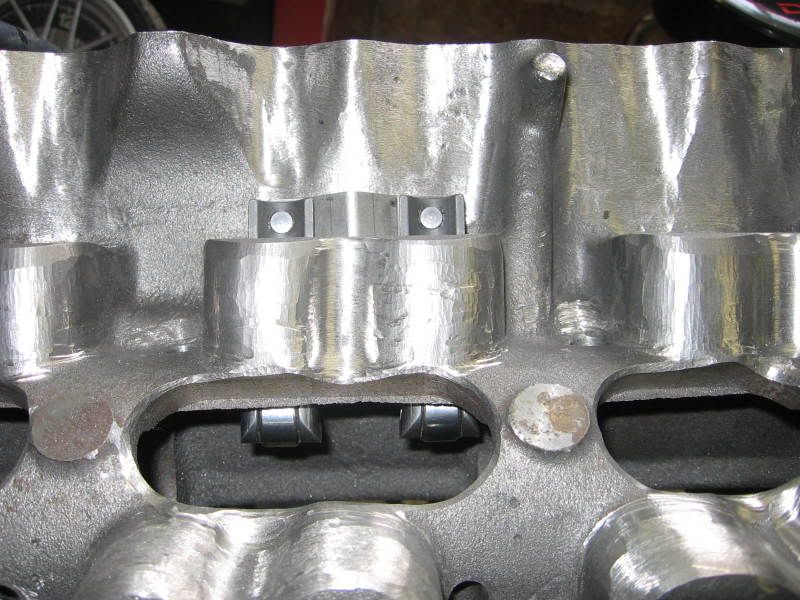

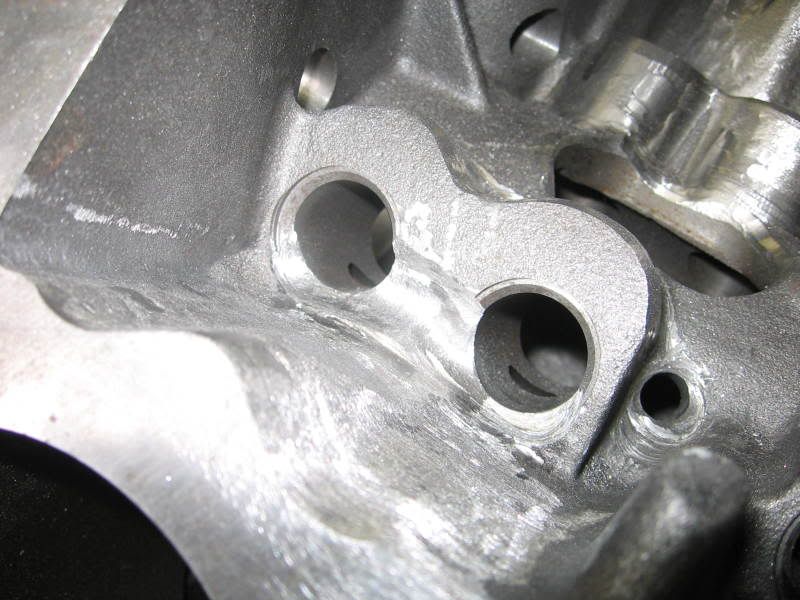

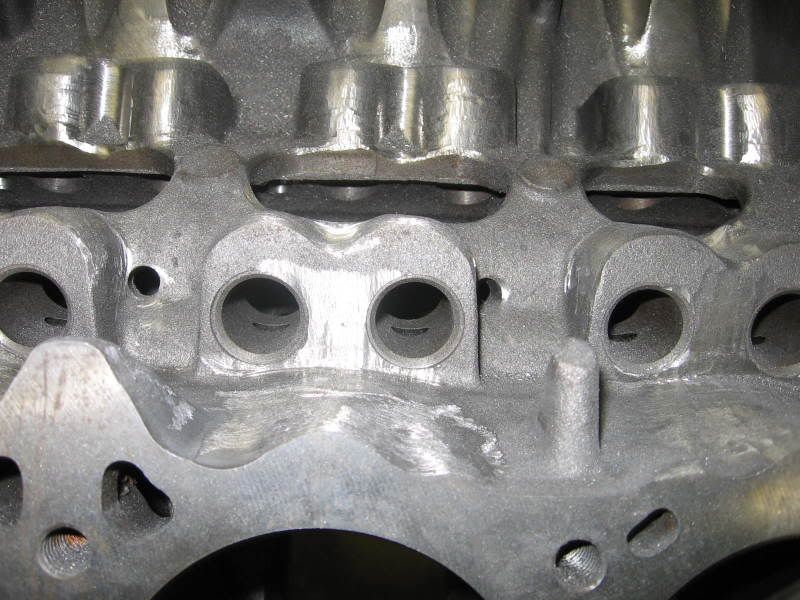

I have built 2 resto-strokers... the 1st is dead because we tried to force a roller cam in (after using ceramics and had bad luck) and broke through to the water jackets (see 4th pix).

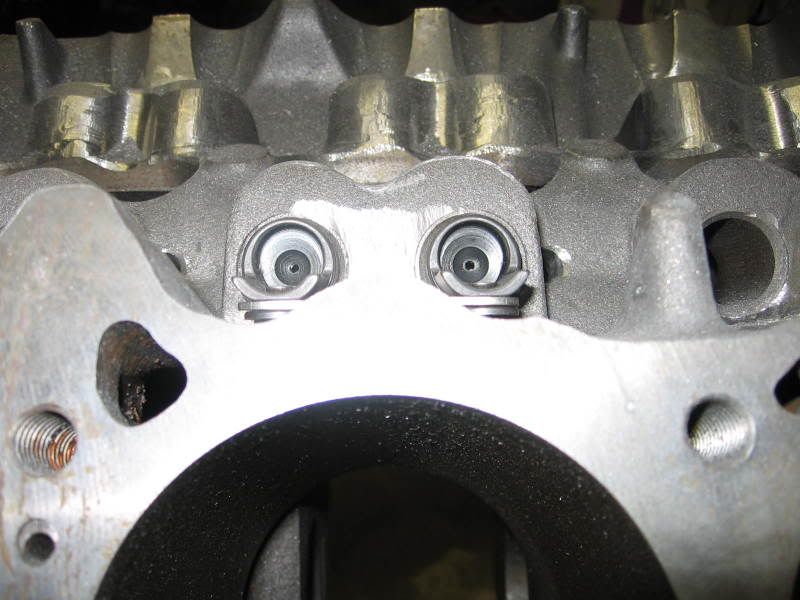

Current build is a siamese block over .060 - (could have gone bigger... lots of meat left) to 422. Intakes are 2.08 and cam is slightly hotter solid (246/250). Only made 526HP (at 5900, not near your 6500) and 537 of TQ but has a nice broad curve. 600 is certainly possible, but the compromise on drivability was more than I was up for (and this is a 4 speed car).

Looking at your specs I am not sure about the dual plane manifold - could have been my set-up but we made more HP and TQ with the Victor. You may want to try a couple of different manifolds while you have the motor on the dyno. If I had it to do again I would have probably gone INDY .... perhaps motor 3!

Also - check your wintage tray - the 4 bolt mains on the block were an issue for me but I did this years ago and maybe that was solved (see pix)

I will admit I grossly overspent and wasted some dollars.... but I think the budget you mentioned may be "exposed". Some the items you mentioned (like remote oiling and pre-lubing) and get real expensive... (I though some of those pix in also!).

I have attached some pix - keep us posted.

Kory

I have built 2 resto-strokers... the 1st is dead because we tried to force a roller cam in (after using ceramics and had bad luck) and broke through to the water jackets (see 4th pix).

Current build is a siamese block over .060 - (could have gone bigger... lots of meat left) to 422. Intakes are 2.08 and cam is slightly hotter solid (246/250). Only made 526HP (at 5900, not near your 6500) and 537 of TQ but has a nice broad curve. 600 is certainly possible, but the compromise on drivability was more than I was up for (and this is a 4 speed car).

Looking at your specs I am not sure about the dual plane manifold - could have been my set-up but we made more HP and TQ with the Victor. You may want to try a couple of different manifolds while you have the motor on the dyno. If I had it to do again I would have probably gone INDY .... perhaps motor 3!

Also - check your wintage tray - the 4 bolt mains on the block were an issue for me but I did this years ago and maybe that was solved (see pix)

I will admit I grossly overspent and wasted some dollars.... but I think the budget you mentioned may be "exposed". Some the items you mentioned (like remote oiling and pre-lubing) and get real expensive... (I though some of those pix in also!).

I have attached some pix - keep us posted.

Kory