Badvert65

Long Time Mopar Nut

OK, this is for racing only, drag racing in particular. There was a Hot Rod magazine article about the aluminum slant 6. When they drag tested it, they discovered that if you remove the belt on the water pump, you will gain about 20 HP. With that in mind, I figure that under drive pulleys should be of some benefit. since they are not readily available, I looked at some items I had lying around. This is what I came up with for practically zero cost.

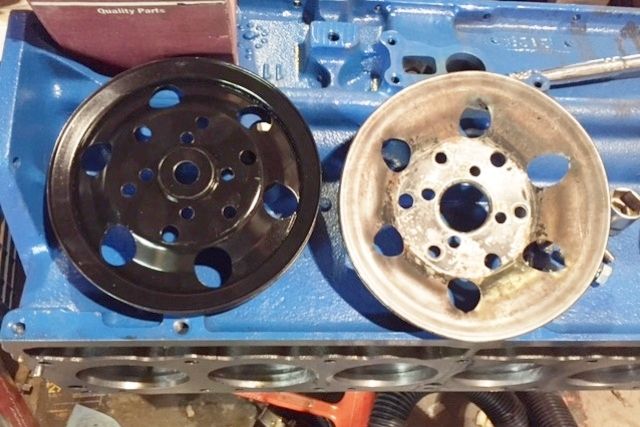

The crank pulley is the pulley off of the AIR pump from my 79 Volare super six. I just had to drill the holes so it would bolt to the balancer. This will yield approximately 25% reduction. This was zero cost, but you can buy the small crank pulley for a Chevy V8 that will bolt up and do the same.

The water pump pulley is actually a slant six accessory crank pulley. I used a steel washer (9/16 I think) in the center and reamed the hole out to 5/8 for the water pump snout. then I just drilled the holes for the water pump bolts. This pulley is too large to be powered directly by the balancer, but the offset clears the balancer with room to spare. I did use spacers on the modified AIR pump pulley to align things. The larger pulley on the water pump will give an additional 10% reduction to the water pump.

My alternator has a double pulley on it and the front most groove will line up with the modified pulleys. Total cost was one flat washer.

It isn't for everyone, but for the drag racer out there, every little bit helps.

The crank pulley is the pulley off of the AIR pump from my 79 Volare super six. I just had to drill the holes so it would bolt to the balancer. This will yield approximately 25% reduction. This was zero cost, but you can buy the small crank pulley for a Chevy V8 that will bolt up and do the same.

The water pump pulley is actually a slant six accessory crank pulley. I used a steel washer (9/16 I think) in the center and reamed the hole out to 5/8 for the water pump snout. then I just drilled the holes for the water pump bolts. This pulley is too large to be powered directly by the balancer, but the offset clears the balancer with room to spare. I did use spacers on the modified AIR pump pulley to align things. The larger pulley on the water pump will give an additional 10% reduction to the water pump.

My alternator has a double pulley on it and the front most groove will line up with the modified pulleys. Total cost was one flat washer.

It isn't for everyone, but for the drag racer out there, every little bit helps.