wardy

Well-Known Member

ok bare with me here, my knowledge about this subject is very limited so ill try my best haha..

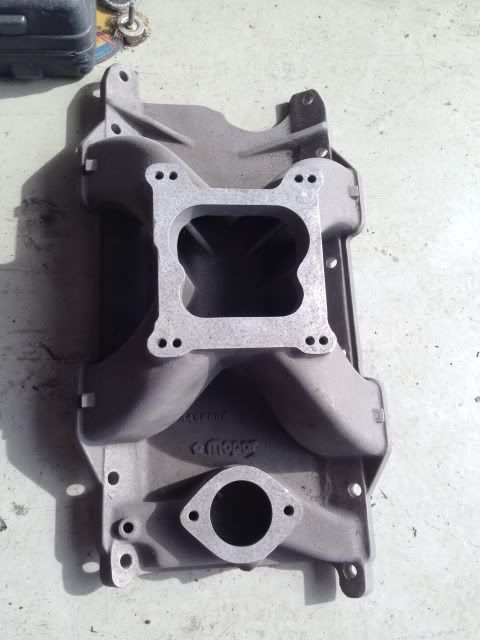

basically im building a 318LA for my 68 aussie valiant, and ive bought a M1 single plain manifold to suit W2 (??) heads, same looking ports but different bolt pattern..

what im wanting to know is if the old bolt holes are welded and new ones drilled in the LA head position does everything else line up correctly? is the head to block angle the same?

it looks as though it will work but but im not sure.. picked the intake up for $180aud so I can afford to modify it.

thanks in advance

basically im building a 318LA for my 68 aussie valiant, and ive bought a M1 single plain manifold to suit W2 (??) heads, same looking ports but different bolt pattern..

what im wanting to know is if the old bolt holes are welded and new ones drilled in the LA head position does everything else line up correctly? is the head to block angle the same?

it looks as though it will work but but im not sure.. picked the intake up for $180aud so I can afford to modify it.

thanks in advance