Yeah, they look big, & not adjusted, i.e. the ball looks offset in the cup a bunch on the closest one...lots of unanswered mysteries yet..and I posed that question in My 1st post. OP needs real help, not sure He's getting it, at all...What pushrods are those? The pushrod cups look suspiciously large like they would hit the rocker arm at full lift.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why do I keep breaking rocker arms?

- Thread starter Slugfarm

- Start date

-

Specs have been hard to track down, as the rebuild was subbed out to a supposed 'slant expert' in Texas (don't have the name). Texas built the engine with a 'performance' cam of unknown nature and I'm pretty sure everything else is stock.

I'll add pushrods to my 'more info needed' list.

#2 and #5 valve adjusters appear taller because those two valves are lower, which seems odd as one is intake and one is exhaust. I realize that this is a dumb question, but are the valves all supposed to be at the same height?

I'll add pushrods to my 'more info needed' list.

#2 and #5 valve adjusters appear taller because those two valves are lower, which seems odd as one is intake and one is exhaust. I realize that this is a dumb question, but are the valves all supposed to be at the same height?

Actually, a lower valve height would require running the adjuster screw down in to take up the clearance, that intake #2 is at least 2-3 threads higher up out. There are also different color adjuster screws, are they all the same length? The exhaust adjuster ball looks small in the cup, like the cup is 3/8" dia., or ball is 1/4" dia. They should be 5/16", even if the pushrods are 3/8", so...Specs have been hard to track down, as the rebuild was subbed out to a supposed 'slant expert' in Texas (don't have the name). Texas built the engine with a 'performance' cam of unknown nature and I'm pretty sure everything else is stock.

I'll add pushrods to my 'more info needed' list.

#2 and #5 valve adjusters appear taller because those two valves are lower, which seems odd as one is intake and one is exhaust. I realize that this is a dumb question, but are the valves all supposed to be at the same height?

Yes. The valve stems should all be the same height with the rocker shafts removed. What does the cam sound like? Can you distinguish it from a stock idle?Specs have been hard to track down, as the rebuild was subbed out to a supposed 'slant expert' in Texas (don't have the name). Texas built the engine with a 'performance' cam of unknown nature and I'm pretty sure everything else is stock.

I'll add pushrods to my 'more info needed' list.

#2 and #5 valve adjusters appear taller because those two valves are lower, which seems odd as one is intake and one is exhaust. I realize that this is a dumb question, but are the valves all supposed to be at the same height?

I'll put it to you like this. When my machinist finished my prototype slant 6 closed chamber head, all the valve stems were within .002" of each other. That's the correct way to do a valve job. Most shops that do most all Chevy stuff never look at that with a critical eye, because since the Chevys have adjustable rockers, they figure it doesn't matter, but it most certainly does.

The engine sort of chugs at idle, and moves a lot, shaking the whole car. Idle at around 750.Yes. The valve stems should all be the same height with the rocker shafts removed. What does the cam sound like? Can you distinguish it from a stock idle?

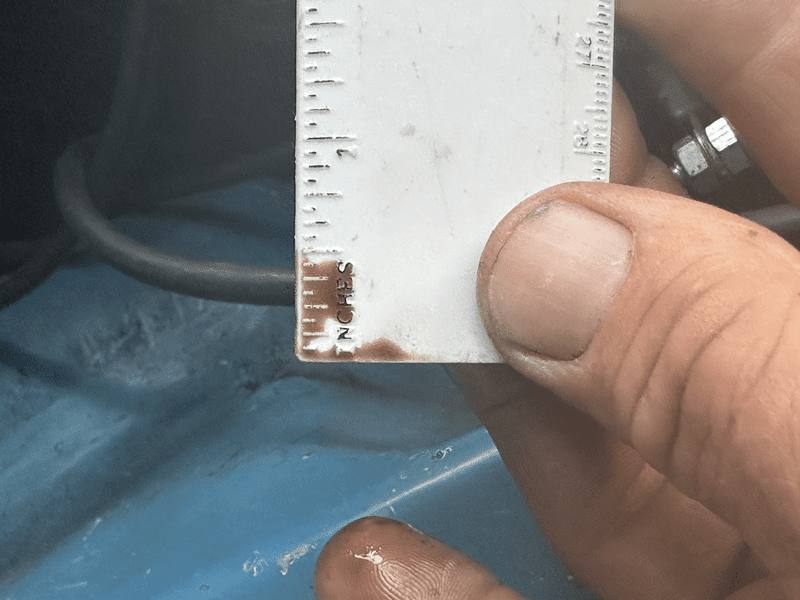

So probably pretty lumpy. I'm just trying to get a feel for maybe how much lift it has. This is why I went with a custom ground cam to my specs. I wanted low lift, because I want none of the problems that come with high lift like coil bind, heavy spring pressure to wear things rapidly or even break things. Do you have a straight edge? You can remove the rocker assembly and put a straight edge across the valve stems and get a good idea how bad off they are. The question then becomes WHY? Were the seats and or ground too far? Did they install hardened exhaust seats too far into the chambers? The list goes on. If you will measure the outside diameter of one of those pushrod cups, I'll measure one that I have and see if we're far apart or not. That just looks strange to me.The engine sort of chugs at idle, and moves a lot, shaking the whole car. Idle at around 750.

How does it sound compared to mine? Be specific.The engine sort of chugs at idle, and moves a lot, shaking the whole car. Idle at around 750.

How does it sound compared to mine? Be specific.

Mine sound slower, heavier, lumpier. Where yours clops, mine clatters. Is this making sense?

In the same vein could put a dial indicator on the lifter and measure cam lift off the base circle. That will provide a decent idea of the cam even without checking timing at .05 and which wouldn't be that much harder but is more work to set up tape or a degree wheel.? You can remove the rocker assembly and put a straight edge across the valve stems and get a good idea how bad off they are.

Yes that tells yours idles slower. Mine produces that idle at "around" 900-950 RPM. It does not like to idle "much" below that without protest, but it will. I simply prefer it right where it is. Do you have a video if it running?Mine sound slower, heavier, lumpier. Where yours clops, mine clatters. Is this making sense?

If the valves are stock sizes, there may be variations in height due to the condition of the head, and chamber casting cyl to cyl. Unless the difference is large, a lot of shops won't do anything to correct this, they simply shim the springs to get the seat load & ht. correct and let the adjusting system handle it(hydraulic or mech.). It's not "ideal", but has been done that way for decades as basic rebuild practice, and performed fine. If the valve has sunk too much, a replacement seat needs to be installed in the head, & brings the stem height back down.Specs have been hard to track down, as the rebuild was subbed out to a supposed 'slant expert' in Texas (don't have the name). Texas built the engine with a 'performance' cam of unknown nature and I'm pretty sure everything else is stock.

I'll add pushrods to my 'more info needed' list.

#2 and #5 valve adjusters appear taller because those two valves are lower, which seems odd as one is intake and one is exhaust. I realize that this is a dumb question, but are the valves all supposed to be at the same height?

Also, here is a factory adjuster in the cup of a 3/8" Crane Chrome-moly pushrod, they are not tight together.

No video but I’ll make one. Not sure how to upload it with a Utube channel though.Yes that tells yours idles slower. Mine produces that idle at "around" 900-950 RPM. It does not like to idle "much" below that without protest, but it will. I simply prefer it right where it is. Do you have a video if it running?

Those pushrod cups appear smaller than his!If the valves are stock sizes, there may be variations in height due to the condition of the head, and chamber casting cyl to cyl. Unless the difference is large, a lot of shops won't do anything to correct this, they simply shim the springs to get the seat load & ht. correct and let the adjusting system handle it(hydraulic or mech.). It's not "ideal", but has been done that way for decades as basic rebuild practice, and performed fine. If the valve has sunk too much, a replacement seat needs to be installed in the head, & brings the stem height back down.

Also, here is a factory adjuster in the cup of a 3/8" Crane Chrome-moly pushrod, they are not tight together.

View attachment 1716114736

Hyper_pak

Old School Chrysler Fan

Some of the adjuster screws are lighter color than the others.

I guess your builder changed a few of them.

Are they all the same size?

I don't see a lot of oil up top, was this the head you started with?

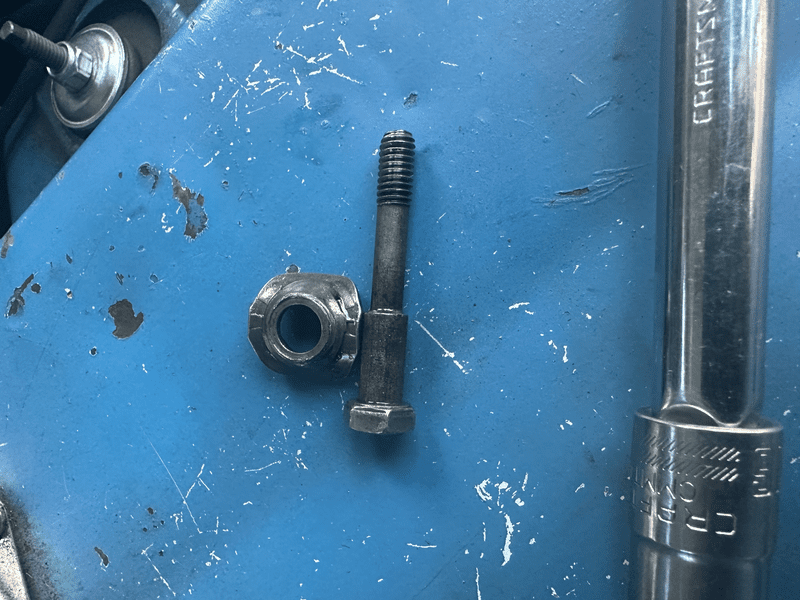

It's an exposed plug head, needs the stepped rear rocker arm mounting bolt.

Need to check that.

I guess your builder changed a few of them.

Are they all the same size?

I don't see a lot of oil up top, was this the head you started with?

It's an exposed plug head, needs the stepped rear rocker arm mounting bolt.

Need to check that.

This is the original head from the first engine I had, which blew a piston after an ill advised 150 mile race up 1-5 against a Cherokee, when I was overly excited about my new 4-barrel, intake and headers on an otherwise stock motor . That was a lot of fun, actually, despite how it ended. The mechanic I went to told me they'd send it off to this unnamed outfit in Texas that supposedly specializes in rebuilding slant sixes, but what actually happened is they jusy ordered an already rebuilt 225 with 'a performance cam' and otherwise pretty much stock. Then, during the break-in period, I blew up a couple rocker arms and they also found some flaw in the Texas head so they milled my old head .100 and reused it. All of this went down before I found this site and SlantSix.org, and knew even less than I do now.Some of the adjuster screws are lighter color than the others.

I guess your builder changed a few of them.

Are they all the same size?

I don't see a lot of oil up top, was this the head you started with?

It's an exposed plug head, needs the stepped rear rocker arm mounting bolt.

Need to check that.

View attachment 1716115002

How do I check this mounting bolt?

Is it a really bad idea to remove the valve cover and start up the engine to watch the rockers? I have a lot of cleanup rags

Pull the rear most rocker shaft bolt and see if it has a stepped shaft. You;ll KNOW IT when you see it. Get a picture of it and post. And no, the slant 6 does not get a ton of oil to the top of the head so you can run it fine with the valve cover off.This is the original head from the first engine I had, which blew a piston after an ill advised 150 mile race up 1-5 against a Cherokee, when I was overly excited about my new 4-barrel, intake and headers on an otherwise stock motor . That was a lot of fun, actually, despite how it ended. The mechanic I went to told me they'd send it off to this unnamed outfit in Texas that supposedly specializes in rebuilding slant sixes, but what actually happened is they jusy ordered an already rebuilt 225 with 'a performance cam' and otherwise pretty much stock. Then, during the break-in period, I blew up a couple rocker arms and they also found some flaw in the Texas head so they milled my old head .100 and reused it. All of this went down before I found this site and SlantSix.org, and knew even less than I do now.

How do I check this mounting bolt?

Is it a really bad idea to remove the valve cover and start up the engine to watch the rockers? I have a lot of cleanup rags.

What is the valve lash set to, & how are they being adjusted??This is the original head from the first engine I had, which blew a piston after an ill advised 150 mile race up 1-5 against a Cherokee, when I was overly excited about my new 4-barrel, intake and headers on an otherwise stock motor . That was a lot of fun, actually, despite how it ended. The mechanic I went to told me they'd send it off to this unnamed outfit in Texas that supposedly specializes in rebuilding slant sixes, but what actually happened is they jusy ordered an already rebuilt 225 with 'a performance cam' and otherwise pretty much stock. Then, during the break-in period, I blew up a couple rocker arms and they also found some flaw in the Texas head so they milled my old head .100 and reused it. All of this went down before I found this site and SlantSix.org, and knew even less than I do now.

How do I check this mounting bolt?

Is it a really bad idea to remove the valve cover and start up the engine to watch the rockers? I have a lot of cleanup rags.

It's OK Rob, I don't suffer from "cup envy", so it's all good!!Those pushrod cups appear smaller than his!

It's OK Rob, I don't suffer from "cup envy", so it's all good!!

Looks like a stepped bolt. The cups are close to 7/16" by my measure, and I measured almost all of them. Also a sh***y picture of adjuster and cup. Shoulda taken more of this one. I ran the engine but couldn't get a shot of the rockers and keep it from stalling out at the same time.

All of this is happening while I'm still driving the car. Despite this discussion it's a total blast to drive, and it's also, other than my work truck, my only vehicle. Since I'm being forced to drive like a gentleman, I'm appreciating how smooth and responsive the car is since the new distributor and tuneup.

All of this is happening while I'm still driving the car. Despite this discussion it's a total blast to drive, and it's also, other than my work truck, my only vehicle. Since I'm being forced to drive like a gentleman, I'm appreciating how smooth and responsive the car is since the new distributor and tuneup.

Damn. Wish I'd seen this while it was still light out. I hadn't notice those in my visual inspection (pretty cursory one I admit). Regarding the ball and cup I've been having difficulty getting a good look at what's going on down there. I think a lot of What we're seeing is distortions from globs of oil. It's very well lubed, and hardly any oil mess after a two or three minute coverless choked idle.OK, @Slugfarm , I grabbed a pic & turned it.

Excuse My poor fingertip scribble, what are the lines/marks at the red arrows, & is the adjuster ball offset as it appears or optical photo illusion(possible)???

View attachment 1716115092

WOW!!! DANGER WILL ROBINSON!!! That 2nd rocker back in the last photo is almost touching the pushrod cup, the adjuster is up too high....sumting wong!!Damn. Wish I'd seen this while it was still light out. I hadn't notice those in my visual inspection (pretty cursory one I admit). Regarding the ball and cup I've been having difficulty getting a good look at what's going on down there. I think a lot of What we're seeing is distortions from globs of oil. It's very well lubed, and hardly any oil mess after a two or three minute coverless choked idle.

WOW!!! DANGER WILL ROBINSON!!! That 2nd rocker back in the last photo is almost touching the pushrod cup, the adjuster is up too high....sumting wong!!

Time to pull the rocker shaft?

-