Is it possible the motor bogs down when ever it has to apply torque? Maybe something I can fix if so?

YES There could be a bad bearing or worn gear that is causing the transmission to bind. Only way I know is to figure out how to get it apart and inspect it. And it could be something in the motor itself

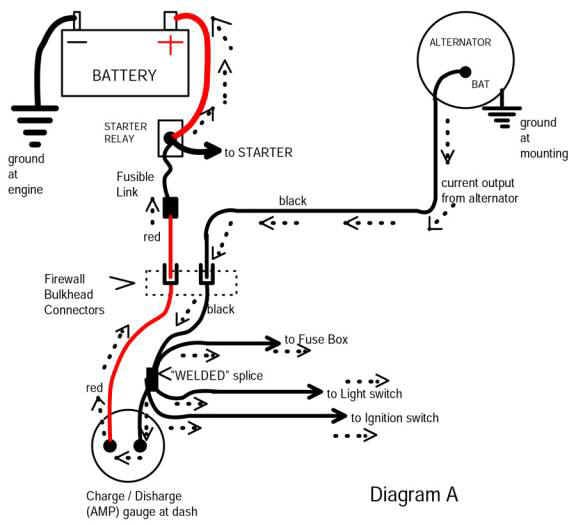

So far as an ACC relay, you could put one, use the IGN switch ACC line to activate the relay, and run a good heavy no10 wire out to the start relay. Put a big fuse link, or auto reset breaker (you can parallel them) but keep away from engine heat the best you can. Heat degrades the ratings on either fuses or breakers

Use a GOOD heavy relay. When I had my old Landcruiser, I actually used a "continuous duty solenoid" for ALL switched loads. The wiring in that think "looked like hell" but there was NO voltage drop.

I could be wrong I hope someone else chimes in. It SEEMS that the 3 speed and variable motors are the same which would suggest that at least temporarily, you could sub a 3 speed switch. I AM NOT sure about this, so you might do some "Googlin'

Here's some stuff I hope helps you

These are screenshots out of my 67 manual so they may or may not be correct, but I've checked several years and all the variable stuff I can find over the years seems to be set up the same.

Below is the screenshot of the 67 Dart switch. The wires go off the page and through the bulkhead connector

V1, going to B on the motor, is coming from UNFUSED switched accessory power directly from the IGN switch via the splice. There should be a breaker on/ in the wiper

The B1 wire, off the bottom B terminal is an OUTFEED feeding power OUT TO the backup light switch. The reason it is show this way on some diagrams is that earlier cars had the backup light switch on the swift mechanism, newer cars went out through the bulkhead and the switch was on the auto trans. All "stick" cars to my knowledge were also on the trans.

The rest of the wires, V3, V4, V5, V6 simply go through the bulkhead and connect with the motor

The exception is V10, hooked to W on the switch, which goes through the bulkhead, and hooks to the washer motor.

Below is a shot of the 67 Dart motor wiring. Just connect the wire numbers, which go through the bulkhead, to the same number above at the switch