You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine pre run oil pump

- Thread starter lomchivok

- Start date

-

I always crank the engine over, 10 seconds or so, and then set the choke. It helps build oil pressure at cranking rpm and pumps gas to the carb. (it's always evaporated out after setting a week or so)

BigBlockMopar

BigBlockMember

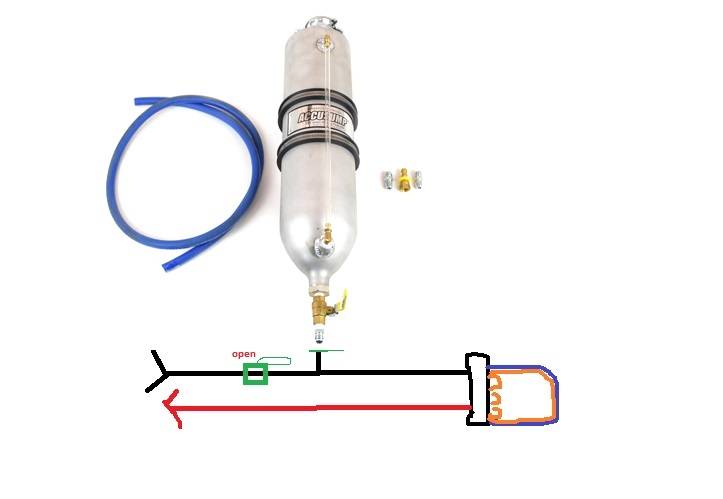

Do a search for "accusump".

It's a pressurized container with oil which you can release before startup.

It's a pressurized container with oil which you can release before startup.

I was thinking of a pump pulling from the oil drain plug through to a remote oil filter with a check valve or a solenoid and back into the oil pressure sending unit boss. You can get timers that will open the solenoid and run the pump for a set time. When the pump stops, Gentlemen start your engine...

72Dart6pack

Harder Better Faster Stronger.

Wow that's a lot of work for no reason. But it's your car.

famous bob

mopar misfit

Well, if the majority of engine wear occurs at startup, why not....

Opinions are like a------- , most everyone has one.

Mine is, if u run a good oil, why worry about it unless it sits for months at a time, it would still have an oil film in the bearings anyway !

72Dart6pack

Harder Better Faster Stronger.

How many factory car companys have done this in the last 100 yrs? Think of the 300 million of cars on the road that don't have this and are STILL on the road. Makes you kinda think.

nm9stheham

Well-Known Member

IMHO, an arguable assumption.... If you look into this start-up wear matter, most of it is due to bore and ring wear due to rich start-up mixtures (especially with carbs) and pistons loose in the bores when cold, so pre-oiling does little to nothing for that. And it does not necessarily put any oil on lifters and cam lobes.Well, if the majority of engine wear occurs at startup, why not....

It ought not hurt anything...... unless something blows out in this extra system's plumbing and wrecks the engine from loss of oil. So you might want to weigh the odds of that versus any perceived benefit.

BTW, the Accusump solution has been around for 4-5 decades.

pishta

I know I'm right....

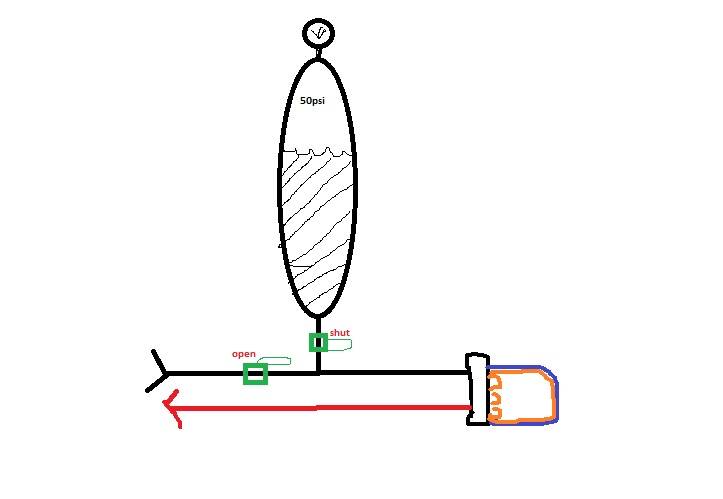

helicopters use a pre oiler. Ever see them go through pre run procedures? One flick sends the oil pressure spiking then they turn on the turbine starters. Accusump or an oil accumulator can be made with an inverted pressure vessel plumbed into the remote feed line (easiest) and a 2 isolation valves. The system is charged when the car is running: Open the accumulator valve and let the running oil pressure fill the reservoir, then shut the valve. Now you got maybe 1/2 qt of oil under 50 psi of air pressure at the top of the vessel. When you want to start the vehicle after a month, close the feed valve behind the accumulator and open the accumulator valve, this will squirt the oil into the engine and register on the oil pressure guage for a few seconds. Open the supply valve, close the accumulator now you can start. Once the car is started, the accumulator can be filled back up with oil pressure whenever you open the accumulator valve to charge, then close that valve again. you could make the valves electric so this could be done in the car, or use a large check valve on the feed side. Whole system would be size of 2 valves and a 16oz water bottle and could mount opposite your rad puke tank for symmetry. Probably more for a monthly car. That accusump bottle is $324!!!

Last edited:

What I know is that nearly every engine I have ever owned eventually develops bottom end noise for a second or two at startup. My 2014 F150 with 80,000 miles and synthetic oil has it now after religiously warming up before driving and oil changes at 5000 miles whether it needs it or not. I drive 100 miles round trip to work and back. Sure engine oils and fuels have anti wear agents in them but when the rods and mains aren't in a fluid floating state, scuffing can occur... that is what I want to avoid. I would think that in a higher compression motor the scuffing effect may be even worse.

72Dart6pack

Harder Better Faster Stronger.

Do what you want. It's not our truck or car.

nm9stheham

Well-Known Member

Interesting.... Have any of them been torn down and looked at what has actually worn? I'd suspect piston slap first, just due to bore and piston wear (but a good synthetic ought to prevent that). And lifter noises 2nd....and maybe advanced ignition timing to aid startup with modern ECM's? And again, if it is indeed the rod bearings, it is just about impossible to know if the wear came from start-up or just running. Knowing how incredibly well a good synthetic protects bearings, I just find it hard to think this is just a startup oiling matter.What I know is that nearly every engine I have ever owned eventually develops bottom end noise for a second or two at startup. My 2014 F150 with 80,000 miles and synthetic oil has it now after religiously warming up before driving and oil changes at 5000 miles whether it needs it or not. I drive 100 miles round trip to work and back. Sure engine oils and fuels have anti wear agents in them but when the rods and mains aren't in a fluid floating state, scuffing can occur... that is what I want to avoid. I would think that in a higher compression motor the scuffing effect may be even worse.

FWIW, I have not experienced anything like that type of noise at 80k miles in a whole bunch of different engines... and my hearing and ability to hear and detect small things like is pretty good. I don't rev the motors at startup, maybe raise them them 1200-1500 RPM at mos, if at all.

You may be onto something though for really high powered engines when you just simply get a lot of chamber pressures all the time; there is a purpose for the Accusump type of product in some situations. I just can't see it based on my own experience with typical factory car engines.

I am going to take a 360 hp 318 with 20,000 miles apart today. Has bottom end noise... although the problem there happened on a burnout where I hit upwards of 8 grand...It kinda got away from me on that one.

And I got 340,000 miles on a Ranger 4.0 never pre oiled it either, it had bottom end noise too.Dont know...I got 326,000 miles on a 94 Dodge 2500 5.9 gas engine....and it has never been pre oiled...

I am going to take a 360 hp 318 with 20,000 miles apart today. Has bottom end noise... although the problem there happened on a burnout where I hit upwards of 8 grand...It kinda got away from me on that one.

LOL.. you might get a rev limiter first.

Lol, sad part of it is that I was on my way to the shop at work to put on an FBO ignition that has a rev limiter built in. Got one now...too late for the 318 but works great on the 408. The 318 still ran great, just had a bit of a tick after that in the oil pan area. Gonna find out what it was today. Last time after Mission raceway friday night street legals it was a wrist pin. This time I'm a thinkin a spun bearing.LOL.. you might get a rev limiter first.

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,148

- Reaction score

- 1,737

I installed an accusump on mine for just that reason. Extra quart in the pan you open the valve and the running oil pressure fills the bottle which creates a pressurized space of trapped air in the bottle. Close the valve and shut off the engine. When restarting just open the valve. Canton makes a adapter that fits between the filter and the block. It was too much of a hassle. Took it out.

B3422w5

Well-Known Member

The oil i run( Lucas hot rod oil) is made for street strip cars that sit between starts for a while.

Also has zinc for my current flat tappet cam. Love the stuff. Clings very good.

Also has zinc for my current flat tappet cam. Love the stuff. Clings very good.

T56MaxTorq

Well-Known Member

“to live or die” That advertisment is fear mongering to sell product at its finest. Somehow the pistons didn’t make their list of “critical engine components.” As nm9stheham mentioned, the pistons won’t see oil from an accumulator system. I’ve opened up junkyard engines that had the intake removed, been rained on for months, and the crank isn’t rusty under the bearings, and the bearings still had a film of oil.

Sure, some helicopters have a pre oil system, but they are also a single engine aircraft and must rotate a large, 12’+ main rotor and a smaller tail rotor. It can take upwards of a full minute for a turbo prop to reach full operating speed and that means it will see lower oil pressures and considerably less cooling air during start. Your SBM will see oil pressure within seconds of engine cranking and you don’t have the strain and load of trying to turn prop mass simultaneously. The equivalent of trying to start up your A-body with it being in 1st gear, every time, cranking over the wheels.

When aircraft are prepared for extreme cold like Antarctica, their engines are equipped with pre heaters, not pre oilers. It’s more effective to heat the oil and surrounding engine components than to prime it with oil. Wear is more from the cold, not a lack of oil starvation.

In your case, keep it in the garage where it is warmer. Add an oil pan and block heater. Fog the cylinders with a winterizer product before storage. And use a high quality oil filter that wont drain-back oil to the pan. If you’re still worried about the bearings after months of storage, why not just pop the distributor and prime the system that way? You can mark the distributor to get it back within 2* of phase, easily. Before the season starts, it’s almost necessary to check and adjust ignition timing anyways.

Sure, some helicopters have a pre oil system, but they are also a single engine aircraft and must rotate a large, 12’+ main rotor and a smaller tail rotor. It can take upwards of a full minute for a turbo prop to reach full operating speed and that means it will see lower oil pressures and considerably less cooling air during start. Your SBM will see oil pressure within seconds of engine cranking and you don’t have the strain and load of trying to turn prop mass simultaneously. The equivalent of trying to start up your A-body with it being in 1st gear, every time, cranking over the wheels.

When aircraft are prepared for extreme cold like Antarctica, their engines are equipped with pre heaters, not pre oilers. It’s more effective to heat the oil and surrounding engine components than to prime it with oil. Wear is more from the cold, not a lack of oil starvation.

In your case, keep it in the garage where it is warmer. Add an oil pan and block heater. Fog the cylinders with a winterizer product before storage. And use a high quality oil filter that wont drain-back oil to the pan. If you’re still worried about the bearings after months of storage, why not just pop the distributor and prime the system that way? You can mark the distributor to get it back within 2* of phase, easily. Before the season starts, it’s almost necessary to check and adjust ignition timing anyways.

Peter Bates

1973 Cuda owner for 36yrs

I am going to take a 360 hp 318 with 20,000 miles apart today. Has bottom end noise... although the problem there happened on a burnout where I hit upwards of 8 grand...It kinda got away from me on that one.

Can you say "spun main" bearing.

-