Articles by krazykuda

Hello folks! The subject has come up on how to check compression. This is a thread to show you how I check MY engines for compression when I build them. I find it easy and simple to do this way, so I thought that I would share it with all. :D

I do ask, since I am writing this on Labor Day...

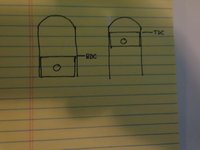

Some people have been asking how to identify a small block oil pan. Here is how to tell the differences in the pans from 273-318-340-360.

Basically the 273-318-340 are interchangeable and there were two basic "series" of them.

Also the oil pans for the trucks are different than the oil pans...

I'm so sick of buying those moving dollies and them breaking when I put an engine on them, even the ones rated for 1000 lb. Hell, I could build a better one myself at home that won't break so easy, or even at all.

So that's what I did.

I had an old metal one with wheels that held the engine...