Charlesvolare

Well-Known Member

I have a 904 behind a 360. 600 rpm idle in gear that jumps to 1100-1200 in park or neutral. I got the transmission and converter together used, but pulled it apart to check it out before putting it in and it was a fresh build, very few miles if any. I was told the customer had it in his build and decided he wanting an overdrive after initially driving his build, 100% believe given the state of the insides. I thought maybe the converter was too tight for my cam at first, so I went to install a higher stall and realized this is a lockup 904 and couldn't use the converter I bought.

The trans has a TCI Scat shift kit, and there is absolutely no felt lockup driving (that's why I thought is wasn't a lockup 904). I'm thinking that maybe the converter is trying to lockup at idle. Any thoughts on what to check? I've blocked the lockup on another 904 before and can do it again if I have to pull the valve body, but shouldn't it lockup normally even with a mild shift kit? Will using a non-lockup valvebody in a lockup trans do this as well?

It may be not locking up at all, might be just a bad idle tune and too tight of a converter, but a converter trying of lockup at idle sounds like a better scenario as well given the rpm drop.

Engine Specs:

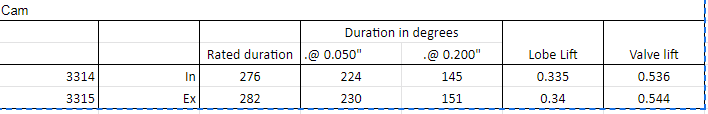

360, 11:1, magnum heads, comp cam (specs inn picture), 750 holley (tuned with wideband, still slightly rich at idle I believe is idling off main circuit)

The trans has a TCI Scat shift kit, and there is absolutely no felt lockup driving (that's why I thought is wasn't a lockup 904). I'm thinking that maybe the converter is trying to lockup at idle. Any thoughts on what to check? I've blocked the lockup on another 904 before and can do it again if I have to pull the valve body, but shouldn't it lockup normally even with a mild shift kit? Will using a non-lockup valvebody in a lockup trans do this as well?

It may be not locking up at all, might be just a bad idle tune and too tight of a converter, but a converter trying of lockup at idle sounds like a better scenario as well given the rpm drop.

Engine Specs:

360, 11:1, magnum heads, comp cam (specs inn picture), 750 holley (tuned with wideband, still slightly rich at idle I believe is idling off main circuit)