I have had this perfect condition NOS 67 Dart V8 Fan Shroud hanging in the rafters of my garage for years. I have decided to clean out and cut it up into bits sized chucks that will fit into my trash can.

Ok Ok get out the paddles and zap your heart back into sinus rhythm.

Really what I am doing is Reverse Engineering it from photos, measurements from my Radiator and photos and measurements graciously supplied by @Bob67Barracuda (Thank you so much Bob)

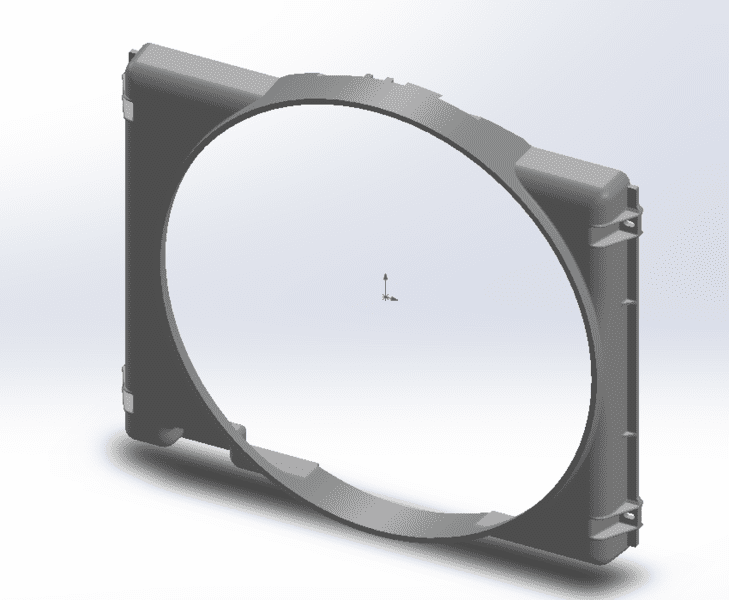

Here is where I am at in the design..

I have a lot of tweaking to do.

Right now I am 3D printing it on my home printer in sections that I will glue together to check for overall fit. I got a price from where I work (we have a 3D printer large enough to print the entire shroud in one piece) but at $800.00 each that's a bit out of my price range.

BTW... YES I KNOW I COULD BUY THE 68 / 69 REPO SHROUD AND IT WILL FIT.

But where would the fun be in that!

Upper left corner

Lower left corner

Ok Ok get out the paddles and zap your heart back into sinus rhythm.

Really what I am doing is Reverse Engineering it from photos, measurements from my Radiator and photos and measurements graciously supplied by @Bob67Barracuda (Thank you so much Bob)

Here is where I am at in the design..

I have a lot of tweaking to do.

- The centering of the fan opening on the shroud

- The notch at the top and bottom where it goes over the radiator

- The notch by the lower rad hose

- The overall height of the top, from photos it looks like the shroud part (not the top arch of the fan opening which is taller than the core) it is taller then the core opening and contoured to fit snuggly to the core and top tank

Right now I am 3D printing it on my home printer in sections that I will glue together to check for overall fit. I got a price from where I work (we have a 3D printer large enough to print the entire shroud in one piece) but at $800.00 each that's a bit out of my price range.

BTW... YES I KNOW I COULD BUY THE 68 / 69 REPO SHROUD AND IT WILL FIT.

But where would the fun be in that!

Upper left corner

Lower left corner

Last edited: