I ordered correct replacement setA little off topic here.......While I am thinking about it...

The WP bolts look new? You know about the driver side shallow timing cover hole correct? Too long of a bolt there and it goes through #1 cylinder. I believe it is the 2nd from the bottom IIRC.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is overspray on cylinder head ok?

- Thread starter J.B.

- Start date

-

Probably wouldn't hurt..........And pop the end caps and clean them out.

Correct for "what"? Are you 100% SURE which lifters you have? That's why I said wait.....but if you're sure, go for it.I ordered correct replacement set

Water pump bolts and yes measured just ordered comp cam 7.23’s adjustable hydraulic lifer/ cam rods which happen to work goodCorrect for "what"? Are you 100% SURE which lifters you have? That's why I said wait.....but if you're sure, go for it.

So then you verified you have hydraulic lifters? I know I'm hammerin on it but I'm just tryin to help.Water pump bolts and yes measured just ordered comp cam 7.23’s adjustable hydraulic lifer/ cam rods which happen to work good

Pic of lifter?

Been watching "Reacher." He says:So then you verified you have hydraulic lifters? I know I'm hammerin on it but I'm just tryin to help.

"Assumptions kill."

Yes they are hydraulic lifters and hydraulic flat tappet camSo then you verified you have hydraulic lifters? I know I'm hammerin on it but I'm just tryin to help.

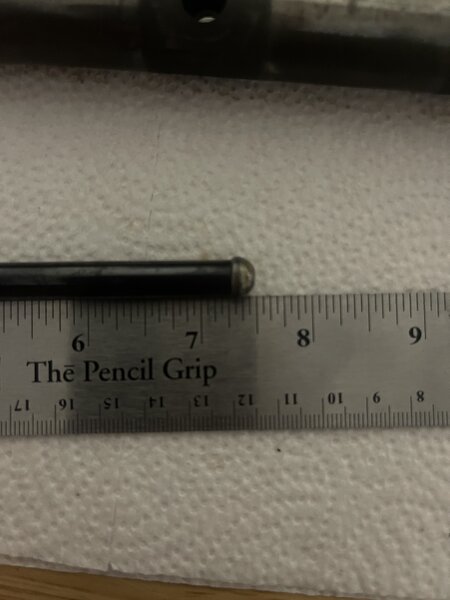

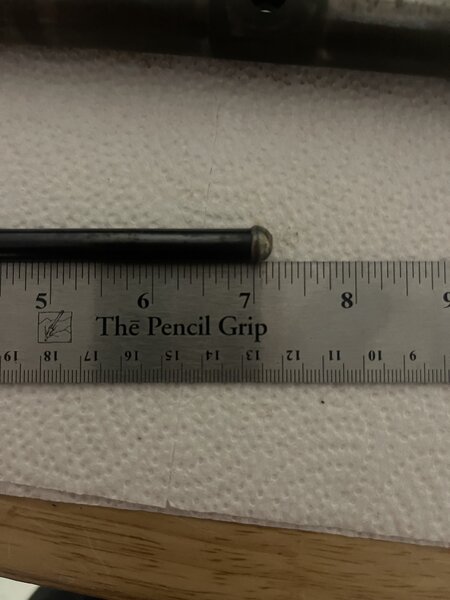

These are sealed power RP-3107 currently listed as an oem mechanical adjustable 273 push rod. what i have with both measurements total length and from bottom of cup seam to tip of ball. The 1st measurement is total at 7.5” and the second is bottom of cup where it meets pushrod to tip of bottom ball at 7.1875 i ordered the summit racing G6450 T/A adjustable rocker hydraulic lifter/cam rods which are 7.389 total and 7.23 bottom cup seam to bottom tip putting me in the proper tolerance for setup

Those are nice shafts. The banana grooves will help a lot. I call um nanner grooves. lol About the only way that setup can be better at this point is if you sent all of it off and got the rockers bushed with bronze bushings. That's a very nice mod, but really unnecessary with a mild hydraulic flat tappet cam. Maybe if you ever upgrade to a more rowdy solid or roller.

See your 1st pic with notch?? There should only be one on each shaft. As a preliminary "check" those go down and to the left when bent over dryhumping the fender.

Shafts look good. For a $4500 engine those should have been cleaned/polished already.

Shafts look good. For a $4500 engine those should have been cleaned/polished already.

Polished up and smoothed out shafts they cleaned up nice and smoothed out the scores

View attachment 1716195432

View attachment 1716195433

Yes the notches were on the left of each sideSee your 1st pic with notch?? There should only be one on each shaft. As a preliminary "check" those go down and to the left when bent over dryhumping the fender.

Shafts look good. For a $4500 engine those should have been cleaned/polished already.

YesAnd down?

Uncle Bob

Shiny paint causes stress.

^^^ THAT ^^^Best thing to do is instead of taking pot shots at length, is use a checking push rod.

Call Smith Brother's and have a set made took a week to week and a half. Well worth the wait.

Don't forget there is a difference between the ball-cup length and the overall length.

I ended up with a 7.080 ball-cup length on a 360, e-heads, hydraulic cam, and 273 rockers.

I used oepushrods, had to call and do things the old fashioned way, but had my parts in under a week.

69FBCuda

Stand back 10' for your viewing pleasure & Safety

"Laid" What is that you speak of, I heard that term many years back and dont recall the true meaning. I do know I've been F**ked" and "Screwed" multiple times throughout the years though, is that the same?if i was still young, dumb, and broke i'd probably roll some dice-- mainly because i had infinite spare time due to my inability to get laid. but even then, i'd still at least clean off most of the paint, and probably check the cam & chain.

it's out, it's accessible, gaskets are cheap. peace of mind carries some weight, if not a monetary value. besides, what's another few days in the timeline. it's not like this thing needs to be on the road for work on monday.

69FBCuda

Stand back 10' for your viewing pleasure & Safety

That's a pretty aggressive cam. Be sure to check for spring bind and rocker clearance at the spring retainer.Here is the engine info from the builder i got the whole setup for $4,500. I have pics and receipts that validated before i bought.

1973 340 block 10.5:1 compression ratio,bored 30 over forged pistons, forged rotating assembly from a 69 block 10/10 crank ,X heads fresh valve job with 530 lift springs. Lunati Voodoo cam part#10200703 494/513 268 /276 duration. Crower cam saver lifters part#66031X3-16, adjustable 273 rockers . Mopar distributor with new plugs and wires.

How to Verify Valvetrain Geometry - Lunati®, LLC.

Lunati Power detailed technical information on how to verify proper valvetrain geometry.

Not sure they could beAre those spring retainers aluminum?

They don't look aluminum to me. Stick a magnet on um and check.

Could be titanium.....LOL, I have 15 from a parts lot sitting, collecting dust.They don't look aluminum to me. Stick a magnet on um and check.

MOPAROFFICIAL

Oogliboogli

Wipe it off with brake cleaner and a terry cloth.

People paint valleys all the time for oil return -travels on smooth faster-

Not a big deal...merely sloppy is all.jmo

People paint valleys all the time for oil return -travels on smooth faster-

Not a big deal...merely sloppy is all.jmo

-