Dont forget thread sealant on the outer exhost manifold studs and the water pump bolts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1967 Dodge Dart 270

- Thread starter Sean Officer

- Start date

-

SNKEBIT

Spending $$ on Mopars

Did you have hardened valve seats put in the heads? Unleaded gas eats the old ones.

70 Dart is where its at !!67 is by far the best A Body.

The GT trim package was clean and doesn't detract from the body lines like the 68 or 69 GT trim does.

It was the start of the entire 67 to 76 dart / duster line.

Far more attractive then Barracudas or Valients

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Dont forget thread sealant on the outer exhost manifold studs and the water pump bolts.

Thank you. Realized I needed to do that earlier today. Was planning to use Permatex Ultra black which is what i used to seal the intake manifold.

Did you have hardened valve seats put in the heads? Unleaded gas eats the old ones.

I did not. Doing this rebuild at home and on a budget. The plan for right now is to get it running solid, then if we truly love it, start upgrading. It probably needs new seats and guides. It is on the ragged edge of being in tolerance.

Last edited:

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

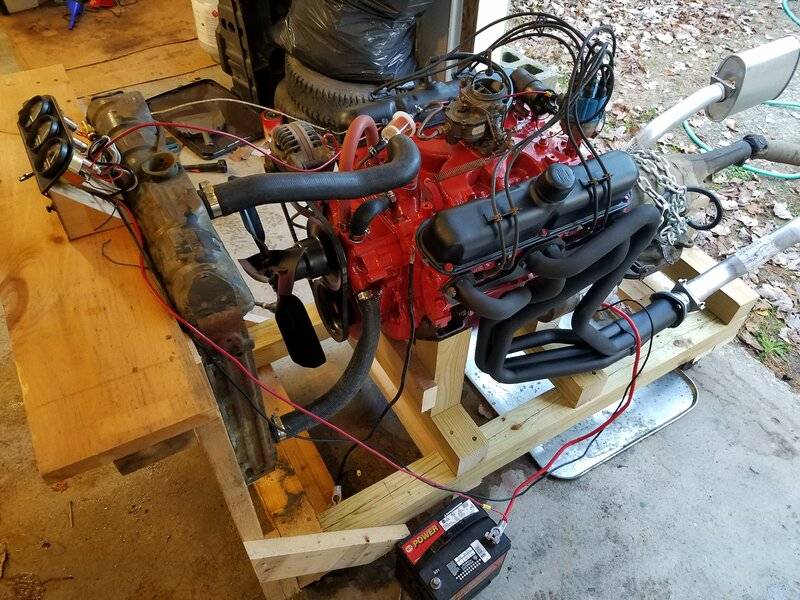

Well, paint day ended up being today. Made sure to seal the water pump bolts and exhaust studs. Then rattle canned the engine and a few of the miscellaneous attachments. Came out ok. Ran out of black so the valve covers still need another coat. Overall I am happy with it. Next up is to design and build a wooden run test stand, rebuild the transmission, then test on it a bit.

Last edited:

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Headers and exhaust got here yesterday. Worked on getting a mock up together so I can design and build the run stand. Waiting on the new alternator bearings to show up, then I will pull that apart and get it cleaned up. Trying to decide whether to wait for the transmission to be done to test it out or pick up some metal and make a mount for the starter. Have parts coming for the transmission rebuild and to help with the run stand. Getting close to testing time.

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Goal for the weekend is to get the engine up and running. Started the building the engine run stand with a bunch of wood we had out behind the outbuilding Thursday after work and made good headway on it today. Still have a bit to do such as set up the control panel and cut and place the transmission supports. Then it is on to mufflers, a jumper for the transmission cooling lines, wiring, hose clamps, fluids, and such. Intermediate shaft is out right now as I plan to prime the oil pump just before I start it. Hopefully all goes well and I will have a good run video by Sunday night. Want to get it as dialed in as I can before it goes in the car. It was bogging hard then the gas pedal was mashed. Not sure if it is a carb issue or if the exhaust was just full of mouse nest. We'll see. Oh yeah. Please don't mind the filthy, leaky transmission. That is next on the rebuild list. Kit got here today along with the new bearings for the alternator.

Last edited:

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Well...today was both good and bad. The good? It's alive!!!! Got it started up, got the timing set and got the idle set. Oil pressure is at around 55-60 psi. The water temp sensor that came with the gauge kit was too big even for the drain plug ports so unfortunately no water temp. would have been handy. We brought it up to 2K RPMs for break in. There was a bit of smoke from the exhaust but it cleared up quickly as the rings seated. There is a bit of clatter from the passenger side and it seemed to run much hotter than the drivers side. I had concerns on if I set the lifter preload correctly or not. My question is in setting zero lash. I learned that you tighten the adjuster until there is no more up and down movement and there is a bit of resistance when spinning the pushrod, then take another half turn on the nut. I was unsure as to how much resistance is too much since the springs begin to compress. Any insight would be greatly appreciated. The bad? About 15 minutes in the radiator decided it didn't want to maintain structural integrity anymore so that ended our test and tune run till I can get a replacement. No major leaks. the oil pan drain plug was only hand tight so there were a couple of drips there until I took a wrench to it and the carb is weeping at the top of the bowl so I will check the float level while I am waiting for a radiator. All in all need to work out some issues but I think it went well for my first time doing this.

abdywgn

dismantler

Well done!

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Been a good day. Got the new radiator yesterday and installed it this afternoon. Got the valve train set properly. Brought the RPM up to 1800, then adjusted the timing until the RPM stopped increasing. Once there took it to 2200 for 20 minutes to finish the break in. Once that was done, brought it to 3500 RPM and set the total timing at 34 degrees to start. Initial clocks in at 14 degrees. Main thing I noticed is the manual says to set fast idle at 700 and normal idle at 500 but once I get to about 600 it dies so the normal idle is set to 700 for now. Could that be the 318 hydraulic cam or do I need to adjust my idle mixture? I know I need to tweak the carb a bit since it is still bogging when I hit the accelerator. I may have failed in my rebuild of the carb. I did notice a potential leak at the front of the intake manifold. It is super sticky though so I am wondering if it is oil or hot sealant since it is directly below where the upper radiator hose goes into the intake. Water temp is sitting around 190. It's just water for the time being. Will put proper antifreeze in it once it is in the car. Thank goodness for the heated garage. I will shoot some video tomorrow. Shot a short one today but it was before we had it dialed in.

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Did some troubleshooting on the engine today. Still trying to get the bugs worked out. Here is the run video I mentioned.

Did some troubleshooting on the engine today. Still trying to get the bugs worked out. Here is the run video I mentioned.

If you would like a nice 4 bbl manifold I have a couple, one stock one edlebrock.

And I have a 400 CFM competetion series Carter that will fit on itIf you would like a nice 4 bbl manifold I have a couple, one stock one edlebrock.

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

If you would like a nice 4 bbl manifold I have a couple, one stock one edlebrock.

PM sent

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Did some more tweaking on the engine last night. Replaced the vacuum lines for the choke pull off and vacuum advance. Vacuum went up from 16 to 18. Going to pick up a new line for the PCV as well once I get a chance. Went back through and did lifter preload again just to be sure they were all set properly. Think I got it right the third time. Took off the carb and tore it down to check the float level, needle, and seat. It is weeping at the top of the bowl and bogs when accelerating from idle. Float has no holes in it and is set correctly and needle and seat are in good condition and functioning. I adjusted the accelerator pump for a longer stroke and that made a bit of a difference, it wasn't bogging as hard or as long. I can hear the big suck in of air when I hit the accelerator and the squirters are instant. I have been reading that several Carter BBD owners have this issue after a rebuild. Will probably change out the carb....to a 4bbl if everything goes well. Got a long weekend coming up so time to get the crane again and hopefully, get through the alternator bearings and transmission rebuild and get it all back in the car.

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

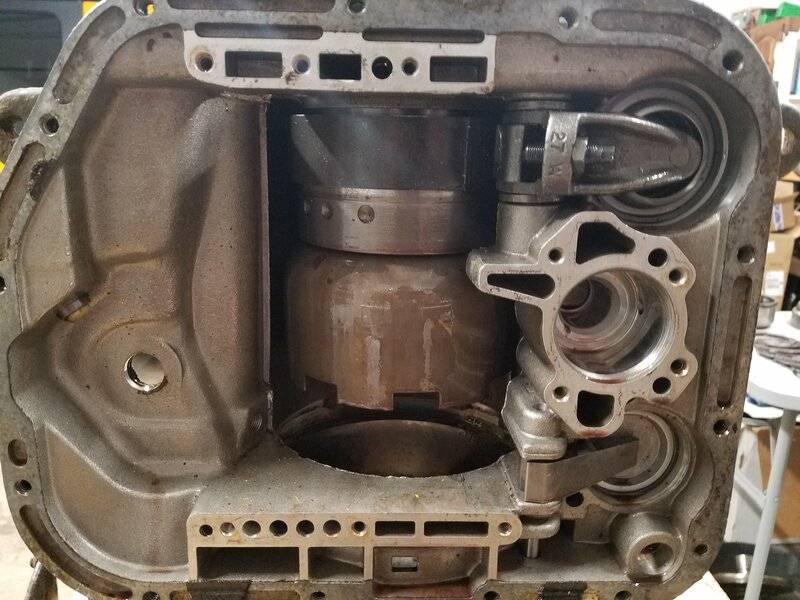

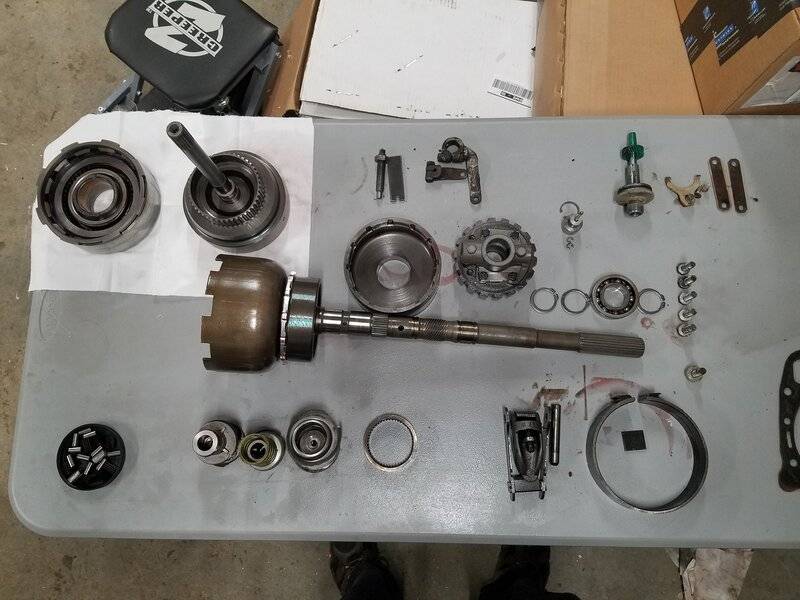

Had an early day at work so decided to get moving on the Transmission. Wanted to do it over Thanksgiving weekend but life intervened. Got started tearing it apart. There is a ton of sludgy material in the pan, the bottom of the housing, and on some of the subassemblies. you can see it best in the bottom of the extension housing. I am interested to see what the clutch rings look like and if that is clutch material or is there something else going on. Unfortunately, got to the point where I need to start pulling snap rings and realized my snap ring pliers are at work so I will grab those tomorrow and get back to disassembly Friday.

lemondana

BlackDart

Nice progress! A suggestion while you have your transmission apart-install an A&A part throttle kickdown kit. It makes driving the little 273, a lot more enjoyable. You wouldn't be sorry. I think they cost right at $100.00.

Ironracer

Gearhead

Makes me wish I would have held onto my 66 outta my Sat.... cool engine, and like what you're doing! Thanks!Got more engine assembly done today. Got the new pushrods and installed them. Put the rockers on and set the lifter preload (hopefully correctly). Got the timing cover and water pump on. Got the oil pump rebuilt and mounted. Got the oil pan on. The intake needs a better cleaning as does one of the valve covers. Plan to get that done next weekend along with a fresh coat of Chrysler Industrial Red and if there is time, design and build a storage/test stand.

View attachment 1715800518

View attachment 1715800519

View attachment 1715800520

View attachment 1715800521

View attachment 1715800523

View attachment 1715800524

View attachment 1715800525

View attachment 1715800522

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Nice progress! A suggestion while you have your transmission apart-install an A&A part throttle kickdown kit. It makes driving the little 273, a lot more enjoyable. You wouldn't be sorry. I think they cost right at $100.00.

Thanks I will check it out! Got a 4bbl intake and carb on the way thanks to a couple of FABO members from a few posts up. This may be just the thing to compliment that upgrade.

If you are going from stock 2bbl to stock 4 bbl there are throttle cable, mount bracket, "kickdown" linkage and transmission lever diferences.to a 4bbl if everything goes well

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

If you are going from stock 2bbl to stock 4 bbl there are throttle cable, mount bracket, "kickdown" linkage and transmission lever diferences.

I have been doing some research on that and found some info on the required parts in one of toolmanmike's threads. Looks like Mancini has the bracket and an extension for the kickdown linkage. What are the differences in the throttle cable and the transmission lever?

Last edited:

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

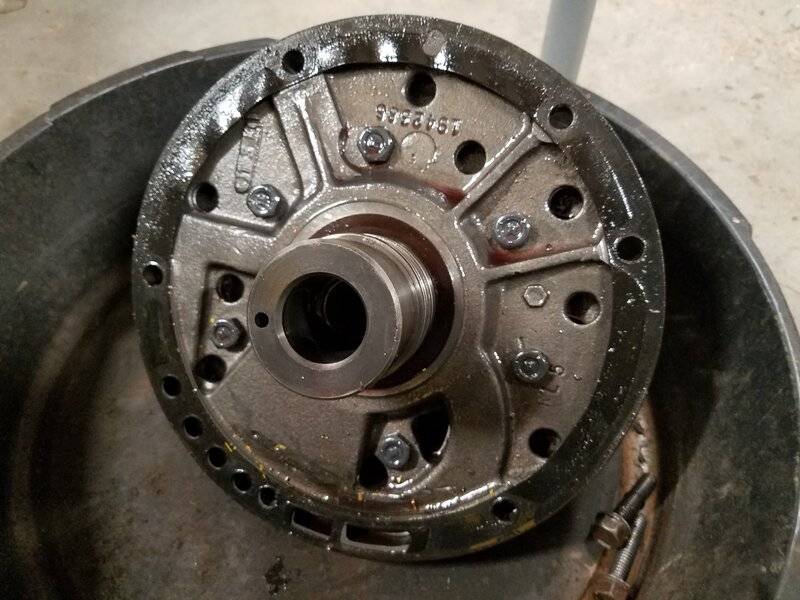

Got a bit more disassembly done today. Got the front pump out (that was fun....). Got into the front and rear clutch packs. Clutches in the front pack look great. Clutches in the rear pack look pretty worn and are starting to show signs oof delaminating. Not surprising for a car sitting for 30 years. Also noticed a few rust spots on some of the casings and such. Wondering if it got a bit of water in it while sitting, or was it some other issue? Will work on it more tomorrow. Also need to do a bit of welding to get a manifold stud out of the block. Had some exhaust leaks. While I realized that the header gaskets that came with my headers were for a larger exhaust port. I figured they would seal. They did not. Picked up a new set from O'reilly and they worked much better. Unfortunately, when I was taking the original manifold off, one of the studs snapped off. That is my only remaining exhaust leak.

Last edited:

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Got the front and rear clutch packs torn apart, cleaned, and rebuilt today. Glad I did, the clutch pistons were practically stuck. My snap ring pliers at work must have been "borrowed" 'cause not there so I picked up a set for $21.... You get what you pay for, those were junk. So I'll be off to return those tomorrow and pick up a real set. Then I can get the rest of the guts out and cleaned up, new seals, and back together. Got the notification that the fuel system minus the front to rear fuel line will be here Friday. Sweet. Just need to get this transmission finished and the engine back in the car. Going to leave the 2 barrel on it for the time being. Have a 4 barrel intake in hand and a matching carb is soon to follow. Still need a bunch of bracketry to make it all work right though so I will do the swap once I have all the stuff.

Sean Officer

1967 Dodge Dart 270 2DHT 360 Magnum/A904

Spent about 8 hours in the garage yesterday. Got the proper snap ring pliers and finished disassembly. Cleaned all the parts and got most of it back together with new seals and gaskets. Also cleaned the case with oven cleaner and blew it dry with the air compressor. I had the front pump in a pan on the floor and stepped on the lip and tossed the bolts all over the garage. Still can't find one of them so I will be off to get a new bolt later today. Also need a smaller torque wrench to set the kickdown and low reverse bands. Sorry for the lack of pics. I got sucked into working and didn't stop to take more as I was working. I did pull apart the planetary gears and got them cleaned and inspected. I should have it all back together and on the engine this week and then get the engine back in the car next weekend. From there it is getting all the linkages installed and adjusted properly, install the exhaust, and install the fuel system which I got most of Friday.

lemondana

BlackDart

Don't forget the A&A part throttle kickdown kit.

-

Similar threads

- Replies

- 12

- Views

- 121

- Replies

- 27

- Views

- 493

- Replies

- 6

- Views

- 216

- Replies

- 7

- Views

- 197

- Locked

- Replies

- 0

- Views

- 172