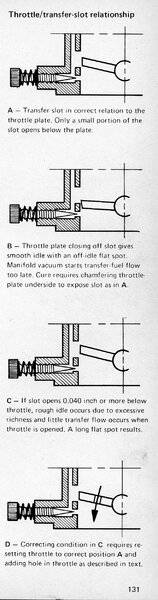

Great advice @AJ/FormS . I had forgotten to mention about the transfer slot setup. The attached photo shows the correct relationship between the throttle blade and the transfer slot. The optimum setting for the blade is to uncover an approx square opening on the transfer slot. It is a real pain to keep removing the carb to check this setting, so I found the best way (with the carb off) is to use the idle screw. Back it out until the blades are completely closed, then turn it in and count the number of turns until you see the square opening. Then you have a reference point. As an example, lets say that the optimum idle screw setting is 1.5 turns in. After advancing the idle timing, the engine rpm will increase and you will thus find you have to back out the idle screw to get your desired idle rpm. This upsets the transfer slot setting!! ie you need to get the idle screw back to 1.5 turns in. A couple of ways to do this:

- On a Holley 4 bbl, you may have an adjustment for the secondary throttle plate idle position (under the throttle plate!!) You can adjust this to allow the sec plates to go further closed (ie reducing the idle speed) and that allows you to screw in the idle screw(to increase the idle rpm) to get back to 1.5 turns out.

- If there are holes drilled in the throttle plates, you may have to reduce their size to allow the correct idle scre setting.

It is a lot of work to get the correct setup when you significantly change the idle timing!!!!

Jim

PS There are a couple of guys who are really good at recurving and/or restoring distributors.

Joe at Joe’s Mopar Distributor Restoration

and Ray at Halifaxhops https://www.forabodiesonly.com/mopar/members/halifaxhops.33547/

- On a Holley 4 bbl, you may have an adjustment for the secondary throttle plate idle position (under the throttle plate!!) You can adjust this to allow the sec plates to go further closed (ie reducing the idle speed) and that allows you to screw in the idle screw(to increase the idle rpm) to get back to 1.5 turns out.

- If there are holes drilled in the throttle plates, you may have to reduce their size to allow the correct idle scre setting.

It is a lot of work to get the correct setup when you significantly change the idle timing!!!!

Jim

PS There are a couple of guys who are really good at recurving and/or restoring distributors.

Joe at Joe’s Mopar Distributor Restoration

and Ray at Halifaxhops https://www.forabodiesonly.com/mopar/members/halifaxhops.33547/