You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1968 Dart Trans Swap

- Thread starter Indy

- Start date

-

Well yes you need a hole large enough for the shifter linkage.

Professor Fate

Push the button, Max...

Yes. If you didn't need to, don't you think the factory would have done it that way instead of making and welding in the extra stampings?

Last edited:

HemiSSDart

Dartus Interuptus

You have to weld in a 4-speed tunnel which is available from AMD.

Ok thanks for infoWell yes you need a hole large enough for the shifter linkage.

Iirc you DO NOT. cut away the cross member. Just the floor pan.

The linkages intertwine around the crossmember.

I googled 68 dart 4 speed tunnel install and this is the 1st video that came up.

Around 8 minutes he started cutting.

Around 9 you can see the hole with the crossmember.

The linkages intertwine around the crossmember.

I googled 68 dart 4 speed tunnel install and this is the 1st video that came up.

Around 8 minutes he started cutting.

Around 9 you can see the hole with the crossmember.

Last edited:

Don't let it scare you. It's not that difficult. THe toughest part of the job is actually locating the 4 speed hump in the floor. And that's dead easy. You can just about throw the hump in from six feet away and it'll land in the right place. Ok....maybe not quite that easy. But if you place it in the floor, there's really only one way it will fit with all of the edge perimeter touching the floor. Really simple. As mentioned, cut around the floor cross member, don't cut it out.Ok thanks for info

I have seen where after marking for the tunnel they mark out around the cross member and cut the floor pan first from under the car in the front and rear of the crossmember, leaving the floor attached to the crossmember. Kind of boxing in the cross member with the original floor.

Not sure if it adds anything to the finish product.

Not sure if it adds anything to the finish product.

pntastar69

Well-Known Member

Lay the tunnel in place, trace it on the floor, measure 1.5" inward around the mark and cut away.

I would recommend tat as much as possible all corners are filleted (curved) to prevent a stress point that might start a crack in the floor down the road.

I doubt the OEM did but they needed to build in "designed obsolescence"

Might be overkill but if you can why not.

" Ounce of prevention..."

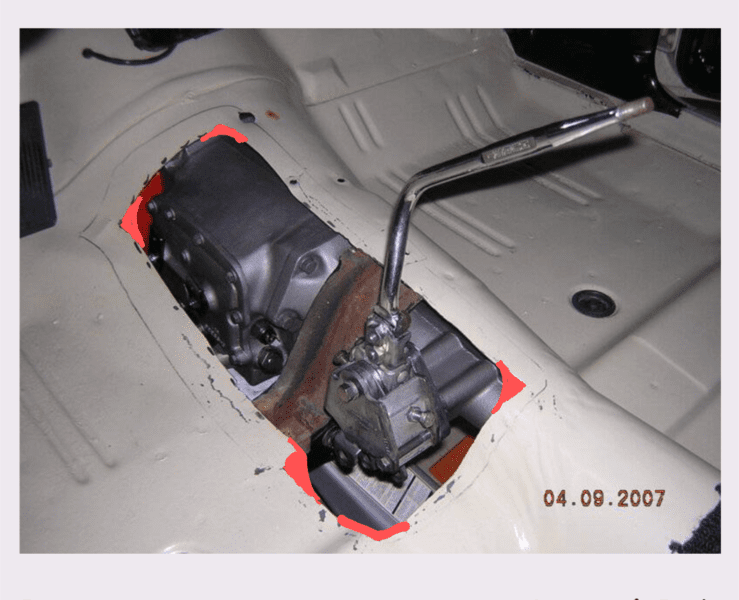

Don't mean to through you under the bus Pntastar69. Your photo was handy.

I doubt the OEM did but they needed to build in "designed obsolescence"

Might be overkill but if you can why not.

" Ounce of prevention..."

Don't mean to through you under the bus Pntastar69. Your photo was handy.

340sFastback

Well-Known Member

Thats a good idea leave the top of cross member boxed in.I have seen where after marking for the tunnel they mark out around the cross member and cut the floor pan first from under the car in the front and rear of the crossmember, leaving the floor attached to the crossmember. Kind of boxing in the cross member with the original floor.

Not sure if it adds anything to the finish product.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,844

The hole doesn't absolutely have to be as big as shown;

1) it just makes it easier to install the shifter parts after the trans is in. and

2) easier to remove the cover if you need to replace broken forks.

3) but honestly, if you pop the distributor cap, and unbolt the crossmember, the back of the trans can be lowered quite far, and my big fat hands can easily get up in there.

4) I welded my hump in so the hole could be pretty ugly, and from the bottom , I bent it upwards into the hump. problem solved. I saved the cut-out piece for if I ever want to convert back, lol.

1) it just makes it easier to install the shifter parts after the trans is in. and

2) easier to remove the cover if you need to replace broken forks.

3) but honestly, if you pop the distributor cap, and unbolt the crossmember, the back of the trans can be lowered quite far, and my big fat hands can easily get up in there.

4) I welded my hump in so the hole could be pretty ugly, and from the bottom , I bent it upwards into the hump. problem solved. I saved the cut-out piece for if I ever want to convert back, lol.

HemiSSDart

Dartus Interuptus

Factory 4-speeds also have a notch taken out of the the crossmember to clear the shifter...

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,844

I did not know that!

-

Similar threads

- Replies

- 0

- Views

- 408

- Replies

- 1

- Views

- 576

- Replies

- 5

- Views

- 180

- Locked

- Replies

- 4

- Views

- 194