Mattax

Just the facts, ma'am

I wouldn't put anything new on that isn't broken.

If the cooling system leaks, then there won't be enough pressure to increase the boiling point.

Could be as simple as a cap leaking or not holding pressure.

Run the engine with the radiator cap off. Starting cold of course.

You should be able to observe (feel and see) the coolant flow. First it will be in the bypass hose and heater hoses only.

when the thrmostat opens you will see the coolanat coming into the top tank and the pump sucking the coolant level down.

You'll have to shut the engine off then or put the cap on.

Engine RPM for slow idle.

Could be many things. Without being there best we can do is give you some general approaches.

Running rough could be the timing but I'm going to guess lean (mixture ratio) or too little air (throttles closed too much).

Look for other sources of air bypassing the entry through the choke horn such as PCV or any other connections that exposes to manifold vacuum. For example there may be an external connection for the choke pull off.

Rather than hunting for various maybe this or that, begin by looking at the spark plug for clues.

Then after fixing the cooling system leak(s), start with a clean set of plugs.

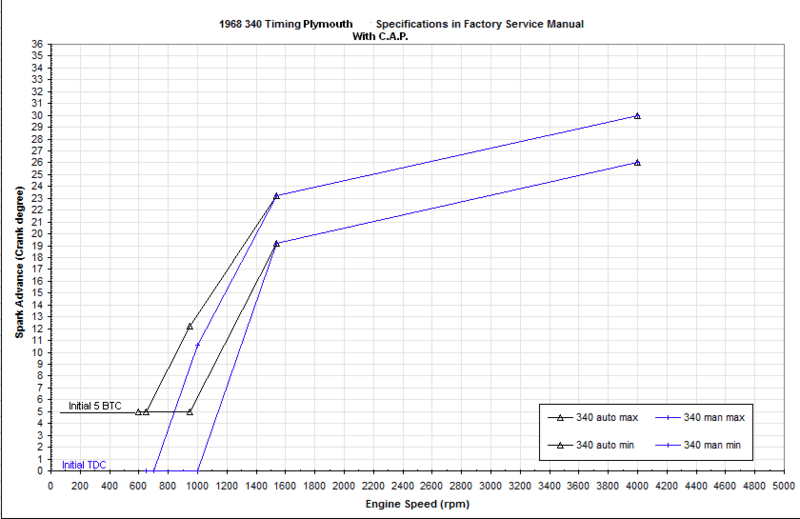

As far as the correct initial timing goes, it will depend on the distributor. If the tag is still on the distributor, see if it matches the number in the shop manual. I can tell you this much. If the timing was advancing very quickly between 750 and 1100 rpm, thats a good indication the mechanism is intended for a low initial timing. If it seems very stable in that range, then it may be that it is non-smog and should use initial around 12* BTDC. (There were no factory non-CAP 340 cars sold in US that I'm aware of)

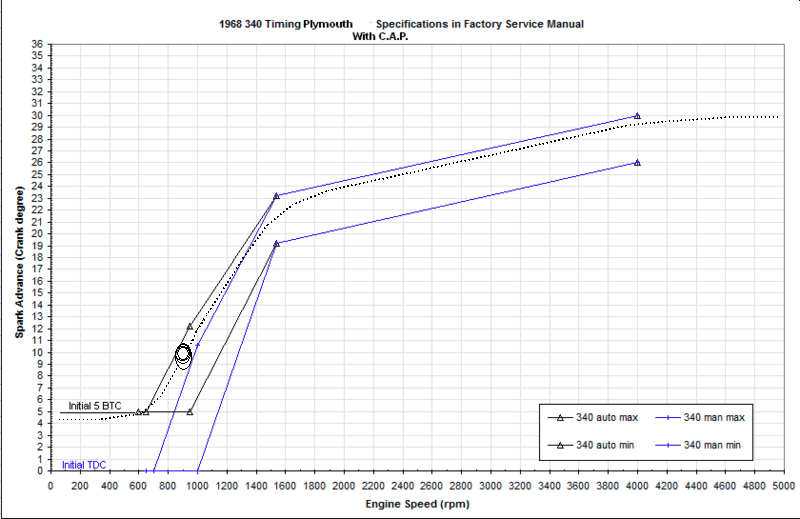

Plymouth factroy timing was supposed to fall in the range shown here. Initial could be set a degree or two higher or lower as needed but the recommended initial was 5 BTDC (auto) and TDC (manual).

Every year there were changes made to the beginning of the advance, and sometimes Dodge used a slightly different initial than Plymouth.

Every engine combination had different timing needs. So a distributor for a different engine will have a different advance. Replacement distributors are too often a mix of parts - close enough for them to sell as one size fits all.

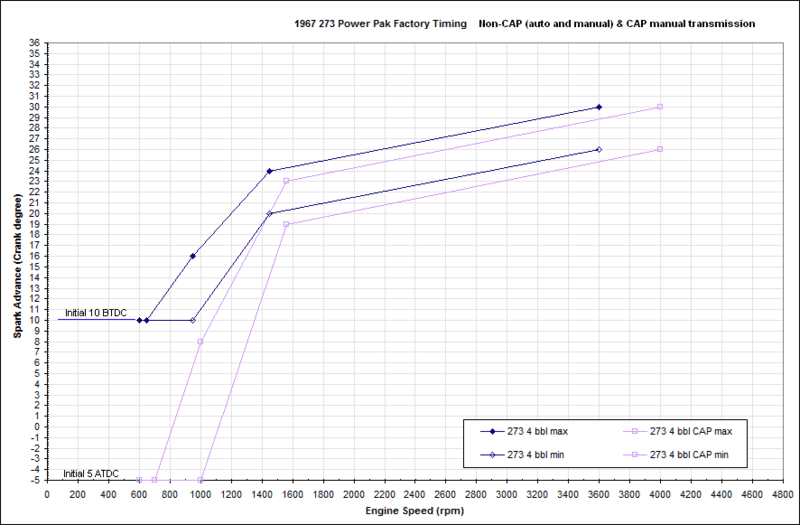

To see the differences between a non CAP and CAP (Clean Air Package) advance on a high performance small block, take a look at the specifications for the 1967 4 bbl 273.

You can see why its important to know something about the distributor's advance before choosing the initial timing.

Also how it can be helpful when you can't get the rpms slow enough to set the initial.

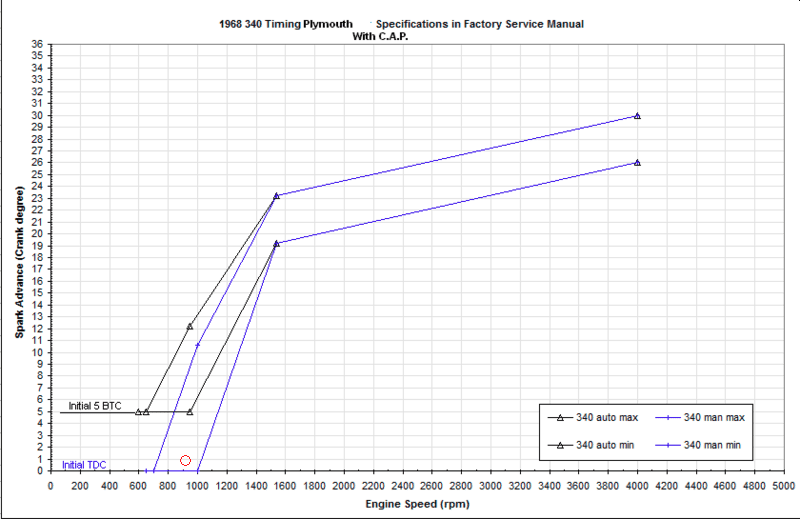

For an example: Lets take your 340 and assume that it has an unaltered distributor from a 1968 340 automatic. At 900 rpm you set the initial at close to TDC. I'll call it 1* BTDC.

That means the timing at other rpms will be something like shown with the dotted line.

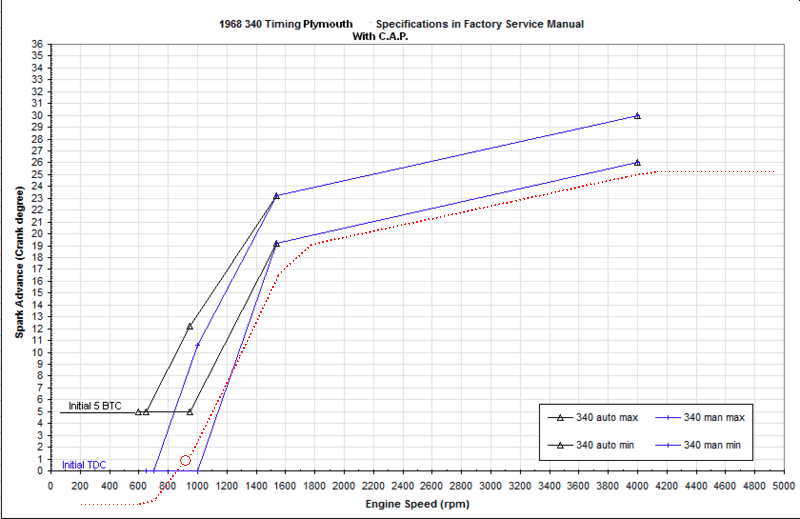

So for that distributor, set the timing at 900 rpm to be somewhere between 5 and 12 BTDC.

Lets say we set it for 9.5* BTDC at 900 rpm; then the rest of the timing will look something like shown with this dotted line.

If the cooling system leaks, then there won't be enough pressure to increase the boiling point.

Could be as simple as a cap leaking or not holding pressure.

Run the engine with the radiator cap off. Starting cold of course.

You should be able to observe (feel and see) the coolant flow. First it will be in the bypass hose and heater hoses only.

when the thrmostat opens you will see the coolanat coming into the top tank and the pump sucking the coolant level down.

You'll have to shut the engine off then or put the cap on.

Engine RPM for slow idle.

Could be many things. Without being there best we can do is give you some general approaches.

Running rough could be the timing but I'm going to guess lean (mixture ratio) or too little air (throttles closed too much).

Look for other sources of air bypassing the entry through the choke horn such as PCV or any other connections that exposes to manifold vacuum. For example there may be an external connection for the choke pull off.

Rather than hunting for various maybe this or that, begin by looking at the spark plug for clues.

Then after fixing the cooling system leak(s), start with a clean set of plugs.

As far as the correct initial timing goes, it will depend on the distributor. If the tag is still on the distributor, see if it matches the number in the shop manual. I can tell you this much. If the timing was advancing very quickly between 750 and 1100 rpm, thats a good indication the mechanism is intended for a low initial timing. If it seems very stable in that range, then it may be that it is non-smog and should use initial around 12* BTDC. (There were no factory non-CAP 340 cars sold in US that I'm aware of)

Plymouth factroy timing was supposed to fall in the range shown here. Initial could be set a degree or two higher or lower as needed but the recommended initial was 5 BTDC (auto) and TDC (manual).

Every year there were changes made to the beginning of the advance, and sometimes Dodge used a slightly different initial than Plymouth.

Every engine combination had different timing needs. So a distributor for a different engine will have a different advance. Replacement distributors are too often a mix of parts - close enough for them to sell as one size fits all.

To see the differences between a non CAP and CAP (Clean Air Package) advance on a high performance small block, take a look at the specifications for the 1967 4 bbl 273.

You can see why its important to know something about the distributor's advance before choosing the initial timing.

Also how it can be helpful when you can't get the rpms slow enough to set the initial.

For an example: Lets take your 340 and assume that it has an unaltered distributor from a 1968 340 automatic. At 900 rpm you set the initial at close to TDC. I'll call it 1* BTDC.

That means the timing at other rpms will be something like shown with the dotted line.

So for that distributor, set the timing at 900 rpm to be somewhere between 5 and 12 BTDC.

Lets say we set it for 9.5* BTDC at 900 rpm; then the rest of the timing will look something like shown with this dotted line.

Last edited: