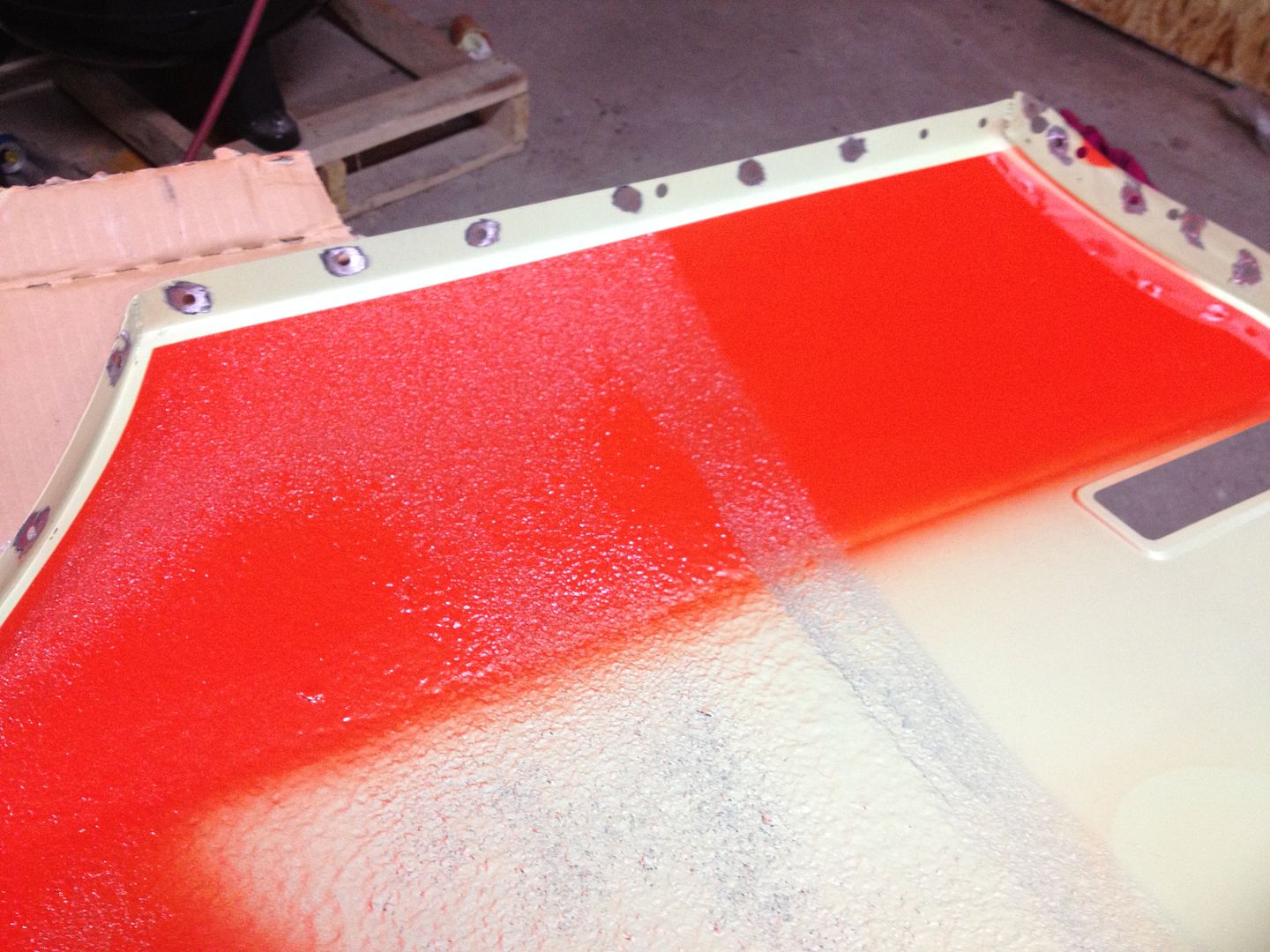

Hemiorangeswinger

Dodge Material

very nice work, how are you liking the fitment of that amd steel so far

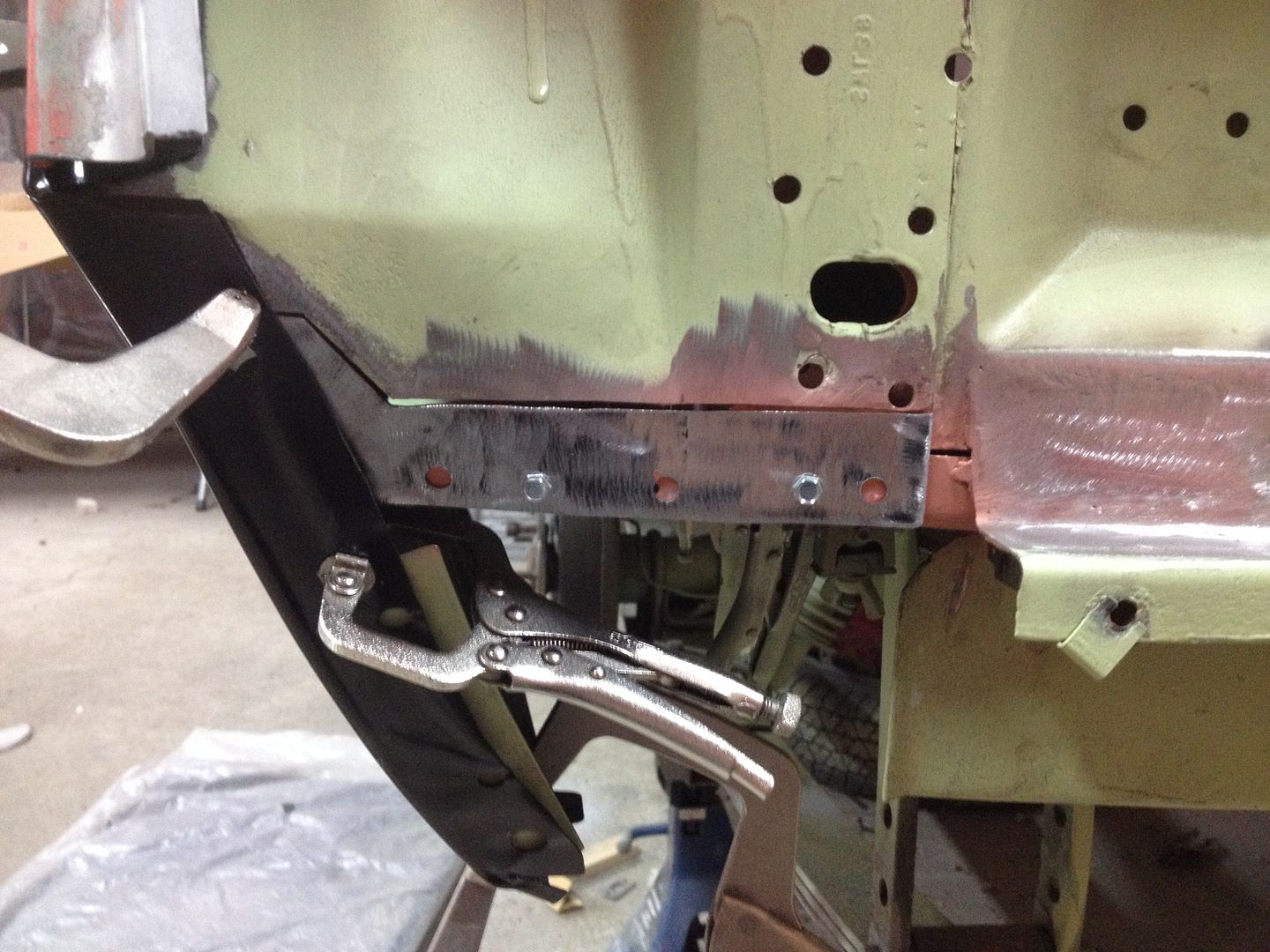

Thanks! So far everything is fitting great with very little adjusting. All the panels are just as thick and sometimes thicker than original.

very nice work, how are you liking the fitment of that amd steel so far

Nice work...It's refreshing to see stuff done the correct way, there's a lot of half-assed work that people on this his forum are proud to post, glad to see your doing it right. Keep up the good work.

Super nice

I love your resto thread and your attention to detail! I can't wait to see it all come together. I too have an EV2 70 Swinger 340. Its almost a twin of this one except for mine came with a 3spd stick originally. Great work so far, keep it going!!