Those will make all that header work worth it Stan

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Dodge Colt

- Thread starter Hyper_pak

- Start date

-

Hyper_pak

Old School Chrysler Fan

I am counting on it.

Speaking about that, I have to make another set for the 170 project.

I will start that this winter.

I hope I learned from my mistakes.

Speaking about that, I have to make another set for the 170 project.

I will start that this winter.

I hope I learned from my mistakes.

That's just sexy right there.

Hyper_pak

Old School Chrysler Fan

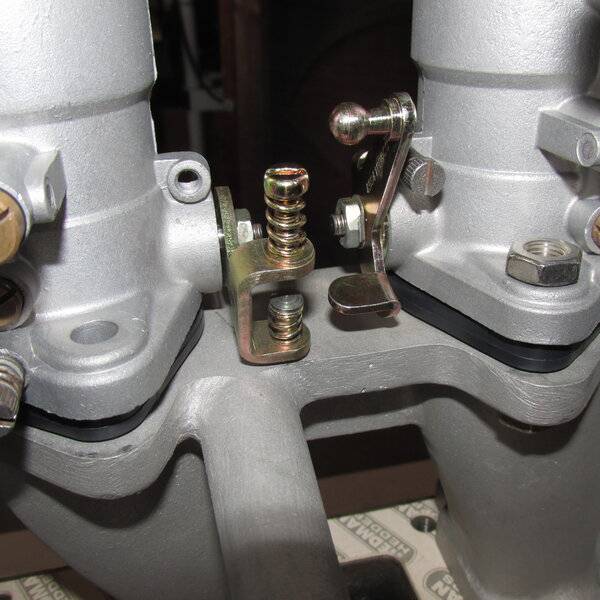

Linkage is always a challenge.

I had purchased a lever set that controlled 2 carbs at the same time.

This is what that looks like installed.

The right lever is supposed to fit between the 2 spring parts on the left lever.

As you can see spacing is something I didn't expect a problem with.

These carbs are spaced too far apart to use this linkage "solution"

And you can see in this picture the dual lever has a different ratio than the single.

So if it had worked I would have created another issue.

And of course the Clifford throttle shaft is shorter than the Redline system.

This is why one of the carbs is an issue on throttle action.

2 Rod End Bearing Supports VS 3 on the Redline.

Redline

If it was easy........

I had purchased a lever set that controlled 2 carbs at the same time.

This is what that looks like installed.

The right lever is supposed to fit between the 2 spring parts on the left lever.

As you can see spacing is something I didn't expect a problem with.

These carbs are spaced too far apart to use this linkage "solution"

And you can see in this picture the dual lever has a different ratio than the single.

So if it had worked I would have created another issue.

And of course the Clifford throttle shaft is shorter than the Redline system.

This is why one of the carbs is an issue on throttle action.

2 Rod End Bearing Supports VS 3 on the Redline.

Redline

If it was easy........

So you're using the Clifford intake?Linkage is always a challenge.

I had purchased a lever set that controlled 2 carbs at the same time.

This is what that looks like installed.

The right lever is supposed to fit between the 2 spring parts on the left lever.

As you can see spacing is something I didn't expect a problem with.

These carbs are spaced too far apart to use this linkage "solution"

View attachment 1715969862

And you can see in this picture the dual lever has a different ratio than the single.

So if it had worked I would have created another issue.

View attachment 1715969864

And of course the Clifford throttle shaft is shorter than the Redline system.

This is why one of the carbs is an issue on throttle action.

2 Rod End Bearing Supports VS 3 on the Redline.

View attachment 1715969865

Redline

View attachment 1715969870

If it was easy........

Hyper_pak

Old School Chrysler Fan

Yea, got in too deep before I saw the light!

It's ok, however.....

The intake has shorter runners, problem with headers on cylinders 2 and 5.

Redline is much straighter because of the longer runners.

And the 2 supports vs 3 on the Redline.

Shorter runners should allow higher RPM.

I bought my intake and 2 carbs off ebay a few years ago.

I found another DCOE in another ebay auction.

Same model numbers, just serial number differences.

All of my Webers are made in Italy, not in Spain.

I am just about at 1K now, after rebuilds and all the little stuff.

I was lucky the 4 barrel and carb clear the hood.

Always planned to run the Webers, and no hood scoop.

It's ok, however.....

The intake has shorter runners, problem with headers on cylinders 2 and 5.

Redline is much straighter because of the longer runners.

And the 2 supports vs 3 on the Redline.

Shorter runners should allow higher RPM.

I bought my intake and 2 carbs off ebay a few years ago.

I found another DCOE in another ebay auction.

Same model numbers, just serial number differences.

All of my Webers are made in Italy, not in Spain.

I am just about at 1K now, after rebuilds and all the little stuff.

I was lucky the 4 barrel and carb clear the hood.

Always planned to run the Webers, and no hood scoop.

Are the Italian Webers better somehow? Forgive me as I know nothing about them.Yea, got in too deep before I saw the light!

It's ok, however.....

The intake has shorter runners, problem with headers on cylinders 2 and 5.

Redline is much straighter because of the longer runners.

And the 2 supports vs 3 on the Redline.

Shorter runners should allow higher RPM.

I bought my intake and 2 carbs off ebay a few years ago.

I found another DCOE in another ebay auction.

Same model numbers, just serial number differences.

All of my Webers are made in Italy, not in Spain.

I am just about at 1K now, after rebuilds and all the little stuff.

I was lucky the 4 barrel and carb clear the hood.

Always planned to run the Webers, and no hood scoop.

Hyper_pak

Old School Chrysler Fan

Like everything today, made somewhere else, cheaper, faster, different.

I have never seen any differences, suppliers just ask the question.

I don't even know the dates on mine but I guess I could find out.

And then there is the history.

Italy.

Ferrari, Maserati, Alfa Romeo.

Spain???

Not so much.

I have never seen any differences, suppliers just ask the question.

I don't even know the dates on mine but I guess I could find out.

And then there is the history.

Italy.

Ferrari, Maserati, Alfa Romeo.

Spain???

Not so much.

Linkage is always a challenge.

I had purchased a lever set that controlled 2 carbs at the same time.

This is what that looks like installed.

The right lever is supposed to fit between the 2 spring parts on the left lever.

As you can see spacing is something I didn't expect a problem with.

These carbs are spaced too far apart to use this linkage "solution"

View attachment 1715969862

And you can see in this picture the dual lever has a different ratio than the single.

So if it had worked I would have created another issue.

View attachment 1715969864

And of course the Clifford throttle shaft is shorter than the Redline system.

This is why one of the carbs is an issue on throttle action.

2 Rod End Bearing Supports VS 3 on the Redline.

View attachment 1715969865

Redline

View attachment 1715969870

If it was easy........

Can you simply weld a piece on the tab to extend it sideways to engage the other linkage?

Hyper_pak

Old School Chrysler Fan

Maybe on the tab, but I have found some right and left hand throttle levers.

I will see what I can work out.

I will see what I can work out.

Hyper_pak

Old School Chrysler Fan

I want my Colt to leave like this!

weedburner

Well-Known Member

Put a 'tamer on it and you may be able to leave like this!

coyote stock nmra drag racing - Search

Factory sealed 460hp NA 302ci Coyote crate engines @ 3000lbs on a spec tune. Dead hooking to mid 9's and low 1.3 60's with a clutchtamer controlling the hit of a diaphragm clutch. They would leave even higher if they could, but if you hit the factory set limit of 7800 the throttle closes.

Grant

coyote stock nmra drag racing - Search

Factory sealed 460hp NA 302ci Coyote crate engines @ 3000lbs on a spec tune. Dead hooking to mid 9's and low 1.3 60's with a clutchtamer controlling the hit of a diaphragm clutch. They would leave even higher if they could, but if you hit the factory set limit of 7800 the throttle closes.

Grant

Hyper_pak

Old School Chrysler Fan

Hi Grant!

Just trying to figure out the install.

Just trying to figure out the install.

Codi

New Member

Hi Stan,

New member here. I build model cars as a hobby and I'm currently doing a mid-70's Pro Stock mid-70's Hardy design (I'll make it in brass btw). I discovered your build and have learned so much from it. My one big question is what diameter are the double main frame rails.........from pics I've found they appear to be about 1 1/4" but in others they appear to be 1 1/2". Your reply would be most welcome.

Thanks in advance,

Codi

New member here. I build model cars as a hobby and I'm currently doing a mid-70's Pro Stock mid-70's Hardy design (I'll make it in brass btw). I discovered your build and have learned so much from it. My one big question is what diameter are the double main frame rails.........from pics I've found they appear to be about 1 1/4" but in others they appear to be 1 1/2". Your reply would be most welcome.

Thanks in advance,

Codi

Hyper_pak

Old School Chrysler Fan

Hello Codi

Welcome to FABO and thanks for your 1st message to me!

Glad you are doing your homework.

Sounds like you are going to do a very detailed build.

The upper and lower frame rails are indeed 1.5 inch.

The main frame bars out to the sills are 1.5 also.

The diagonal bars from the 2 frame rails are 5/8.

Mr. Hardy used a lot of different size bars, the passenger side bar on the cage is smaller.

Feel free to ask any questions about the construction as it has not been changed in 40+ years.

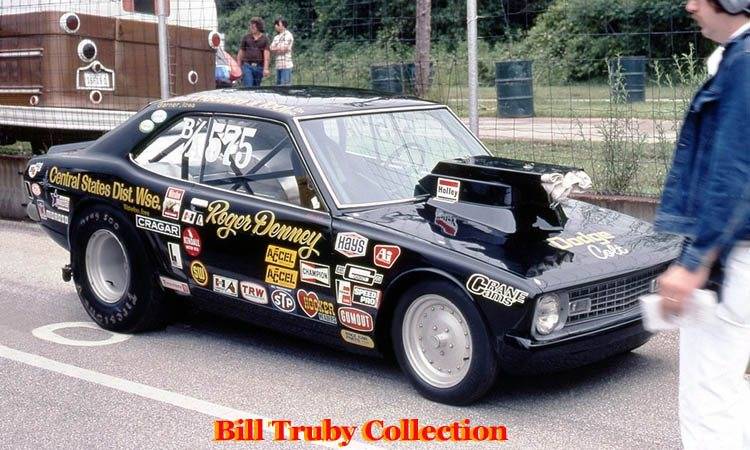

Pretty sure there were many Hardy Colts done but I can only be sure of 4.

Roger Denny, became the Rod Shop Colt, Became the Sox White Colt, Mark Panos last.

Pretty sure Roger Denny had the first Hardy Colt.

Ronald Lyles, this was a Sox team Colt, was later driven by Ronnie Sox Red/White and Blue.

Billy Stepp got one.

Cashed at Bristol after the wheelie bars were not put down.

There are pictures of it being taken apart and statements about that being the end of it.

However..... I will just leave it as gone.

And mine, Kocanda and Patrick.

The current restored S&M Colt is the Lyles Colt.

It originally had rectangular front frame rails per the NHRA Rules at the time.

Welcome to FABO and thanks for your 1st message to me!

Glad you are doing your homework.

Sounds like you are going to do a very detailed build.

The upper and lower frame rails are indeed 1.5 inch.

The main frame bars out to the sills are 1.5 also.

The diagonal bars from the 2 frame rails are 5/8.

Mr. Hardy used a lot of different size bars, the passenger side bar on the cage is smaller.

Feel free to ask any questions about the construction as it has not been changed in 40+ years.

Pretty sure there were many Hardy Colts done but I can only be sure of 4.

Roger Denny, became the Rod Shop Colt, Became the Sox White Colt, Mark Panos last.

Pretty sure Roger Denny had the first Hardy Colt.

Ronald Lyles, this was a Sox team Colt, was later driven by Ronnie Sox Red/White and Blue.

Billy Stepp got one.

Cashed at Bristol after the wheelie bars were not put down.

There are pictures of it being taken apart and statements about that being the end of it.

However..... I will just leave it as gone.

And mine, Kocanda and Patrick.

The current restored S&M Colt is the Lyles Colt.

It originally had rectangular front frame rails per the NHRA Rules at the time.

Codi

New Member

Hello Codi

Welcome to FABO and thanks for your 1st message to me!

Glad you are doing your homework.

Sounds like you are going to do a very detailed build.

The upper and lower frame rails are indeed 1.5 inch.

The main frame bars out to the sills are 1.5 also.

The diagonal bars from the 2 frame rails are 5/8.

Mr. Hardy used a lot of different size bars, the passenger side bar on the cage is smaller.

Feel free to ask any questions about the construction as it has not been changed in 40+ years.

Pretty sure there were many Hardy Colts done but I can only be sure of 4.

Roger Denny, became the Rod Shop Colt, Became the Sox White Colt, Mark Panos last.

Pretty sure Roger Denny had the first Hardy Colt.

Ronald Lyles, this was a Sox team Colt, was later driven by Ronnie Sox Red/White and Blue.

Billy Stepp got one.

Cashed at Bristol after the wheelie bars were not put down.

There are pictures of it being taken apart and statements about that being the end of it.

However..... I will just leave it as gone.

And mine, Kocanda and Patrick.

The current restored S&M Colt is the Lyles Colt.

It originally had rectangular front frame rails per the NHRA Rules at the time.

View attachment 1715973615 View attachment 1715973616 View attachment 1715973618 View attachment 1715973619

Codi

New Member

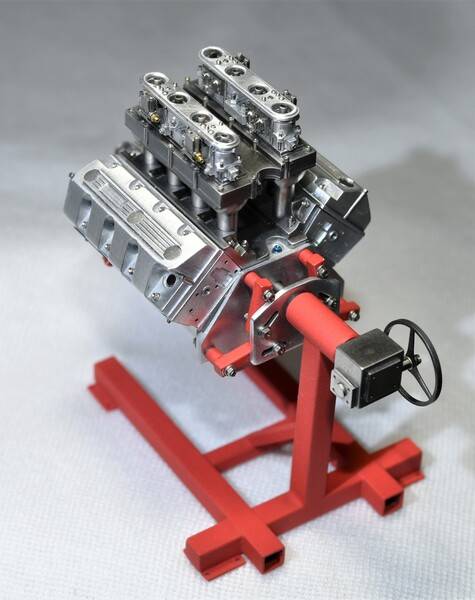

WOW, what a fast reply sir. The information is exactly what I was seeking. I also appreciate your willingness to let me reach out should I have further questions. I'll probably have some more but yes, I've been doing my best to research Mr. Hardy's work and timelines. I'm building it as a 75' Pro Stock / Match Race car. I build 1/25th scale (car is about 6 1/2" long) Sadly, I LOVE Colt's but there are no kits produced for me to do one. I did buy a Japanese kit and cut it up to get the proportions correct but I set it aside and went Maverick instead. It's not going to be an exact replica but more of a "what if". Big fan of Gapp & Roush. The completed engine I machined out of aluminum as a Boss 494 Can Am motor with dual in-line Autolite carbs. Engines done and some other important bits but now onto the chassis which I'm about to draw up. Will do the double frame rail with ladder bar set-up. Dana 60 among other goodies.

I don't mean to hi-jack your thread and if you're curious you can find my builds at "Steppenwolf56" (FOTKI pics)......again, my sincerest thanks and I'll be sure to follow along as you near completion of your car. Cheers

I don't mean to hi-jack your thread and if you're curious you can find my builds at "Steppenwolf56" (FOTKI pics)......again, my sincerest thanks and I'll be sure to follow along as you near completion of your car. Cheers

Hyper_pak

Old School Chrysler Fan

I don't mind, waiting for early Sept to race again.

I have the Doyusha Colt, Arrow and Challenger kits for my projects when I start back on models.

There is a guy on Ebay who had resin pro stock kits for sale.

I am going to use some Ross Gibson resin Hemi's in my kits.

Sox and Glidden cars will get small blocks.

Here is Don and I next to the Billy Stepp-Ronnie Sox Arrow that he built.

I have the Doyusha Colt, Arrow and Challenger kits for my projects when I start back on models.

There is a guy on Ebay who had resin pro stock kits for sale.

I am going to use some Ross Gibson resin Hemi's in my kits.

Sox and Glidden cars will get small blocks.

Here is Don and I next to the Billy Stepp-Ronnie Sox Arrow that he built.

Just curious about what role, if any, the AMC Hornets might have had in the big time?

Hyper_pak

Old School Chrysler Fan

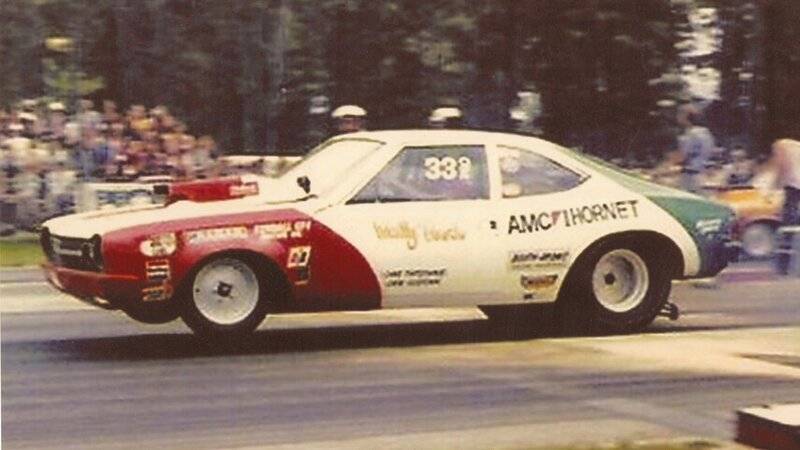

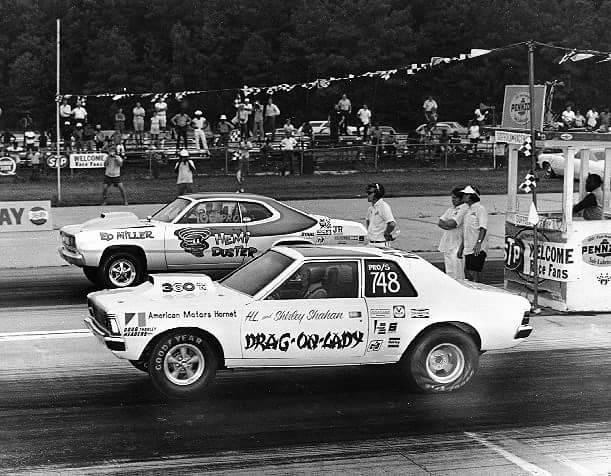

Shirley Shahan ran a early Hornet Pro Stock.

AMC played with the Gremlin first, but performance was not great.

Booth ran the later Hornet with a lot of success.

AMC played with the Gremlin first, but performance was not great.

Booth ran the later Hornet with a lot of success.

II was thinking Shirley was into those AMCs.Shirley Shahan ran a early Hornet Pro Stock.

AMC played with the Gremlin first, but performance was not great.

Booth ran the later Hornet with a lot of success.

View attachment 1715973775

View attachment 1715973773

RockinRobin

Well-Known Member

Just in case you haven't seen this video:

Hyper_pak

Old School Chrysler Fan

I have seen it and asked him some questions, never heard back from him.

I plan on some long stacks after seeing the fog in the intakes, that was interesting.

I plan on some long stacks after seeing the fog in the intakes, that was interesting.

Hyper_pak

Old School Chrysler Fan

Working on life stuff.

My oldest son had the engine in his escape go bad.

I am changing that out to help him out.

That 1.6 is so stuffed in this little SUV, I could not be a mechanic in this day and age.

It took me a week and a half to get the head off.

Only to find a crack in the cylinder wall.

I was planning on towing to Clay City for the Slant Six race a week ago.

The weather was iffy and with my 1000 mile tow each way I chose not to go.

They were able to get the qualifying runs in on Saturday before the rain came.

The track ended up cancelling the rest of Sat. and Sunday.

Sucks for the racers, but I saved my tow money for the next event.

I have been working on the Weber linkage in my spare time.

I think, think, I have it worked out.

I forgot to buy left handed 10-32 nuts from McMaster Carr for the linkage rods.

I hope I can find them locally.

In this picture you can see most of the parts used to open 3 carbs at the same time.

I need to fab the throttle cable bracket now.

My oldest son had the engine in his escape go bad.

I am changing that out to help him out.

That 1.6 is so stuffed in this little SUV, I could not be a mechanic in this day and age.

It took me a week and a half to get the head off.

Only to find a crack in the cylinder wall.

I was planning on towing to Clay City for the Slant Six race a week ago.

The weather was iffy and with my 1000 mile tow each way I chose not to go.

They were able to get the qualifying runs in on Saturday before the rain came.

The track ended up cancelling the rest of Sat. and Sunday.

Sucks for the racers, but I saved my tow money for the next event.

I have been working on the Weber linkage in my spare time.

I think, think, I have it worked out.

I forgot to buy left handed 10-32 nuts from McMaster Carr for the linkage rods.

I hope I can find them locally.

In this picture you can see most of the parts used to open 3 carbs at the same time.

I need to fab the throttle cable bracket now.

Jeff Seighman

aka jeffnmo

Great stuff, get er done.

-

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 3

- Views

- 165

- Replies

- 3

- Views

- 872