I would not mill the intake. Mill the intake side of the heads, .020 means .019 off the intake side of the head for small block Mopars. I always do both.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

273 302 318 340 build

- Thread starter 4spdragtop

- Start date

-

If you mill the intake, the intake and heads will always have to be installed together. I did that with my 273 and wish I hadn't.

4spdragtop

Well-Known Member

Thanks for the specs 66fs! Those ones I posted are out of a mopar sb engine book.

I dont want to do any machining on the intake.

What about the bigger valves? Is it worth it with stock pistons? My spidey sense says no but the cost is the same.

Thanks guy's

I dont want to do any machining on the intake.

What about the bigger valves? Is it worth it with stock pistons? My spidey sense says no but the cost is the same.

Thanks guy's

I would not mill the intake. Mill the intake side of the heads, .020 means .019 off the intake side of the head for small block Mopars. I always do both.

If you mill the intake, the intake and heads will always have to be installed together. I did that with my 273 and wish I hadn't.

I think the bigger valves are only worth it if you are seriously porting the heads. Not really necessary for what you want, I think.

4spdragtop

Well-Known Member

I am not against doing diy port work on the heads. I just seem to be going down the same road with the 318 (stock low comp pistons)

Makes me almost contemplate putting Kanter commando pistons in the 273. I think landed to me about $600 canadian. Then bearings gaskets and now call it close to a grand.

Makes me almost contemplate putting Kanter commando pistons in the 273. I think landed to me about $600 canadian. Then bearings gaskets and now call it close to a grand.

I think the bigger valves are only worth it if you are seriously porting the heads. Not really necessary for what you want, I think.

nm9stheham

Well-Known Member

IMHO, I would not hesitate to go with the 1.88" valves if the price is the same IN THE smaller chamber heads. In low to mid range, I am sure it will translate into better cylinder filling. Remember, with low compression, not only is the compression lower, the amount of spent gases pushed out each exhaust stroke is less (due to more uncleared volume) and any spent gases left in the cylinder is like having an EGR system in the engine..... So anything you can do to help make it easier to clear and then refill the cylinder is gonna help. It is one of those things that contributes to overall efficiency. It is also going to make the heads respond better to any cam changes you make, both in cam specs and cam timing; the small size of the stock valves is one factor that 'gets in the way' to some extent of the cam controlling the air flow.

If you are having trouble with the idea of higher CR pistons, then forget the 3671587 heads. They are going to just mean more CR work to make it work for you in street use.

If they mention any option like a Serdi cut under the seats, I would do that too if not too pricey and in budget. But not all shops have that and it is not normally free!

If you are having trouble with the idea of higher CR pistons, then forget the 3671587 heads. They are going to just mean more CR work to make it work for you in street use.

If they mention any option like a Serdi cut under the seats, I would do that too if not too pricey and in budget. But not all shops have that and it is not normally free!

Last edited:

mullinax95

Well-Known Member

Hi Mully, haven't heard from you in a while...

Good to see you're back....

It's good to be back with you numb skulls..... lol

I have started tinkering with my cuda again and needed yalls advise. Replacing the top end on my 360. Been PMing some members on here to get much needed advise.

Chart shows it starting at .020" Can I then assume head could be milled 0.015" (assume safely) without needing to machine intake?

[/QUOTE

You need to read this.... just so you won't run into problems. I wished I had read this before I put together my 360 because I had problems with my heads sucking in oil from the lifter valley.

INTAKE SEALING

I'm going to do this procedure with the new intake and the Eddy heads just to make sure the mating surfaces are correct.

Last edited:

It's good to back with you numb skulls..... lol

I have started tinkering with my cuda again and needed yalls advise. Replacing the top end on my 360. Been PMing some members on here to get much needed advise.

We can help you with advice if you need it...

and I'm not numb skull - I'm numb nuts....

4spdragtop

Well-Known Member

So another option.

I found a 1974 318.No heads or intake. Bore is .030 over, pistons have 4 valve reliefs. Seller sounds honest. It was in his Duster(340 car)

He didn't do the "work" on the engine but was told to only run it on 93 octane and was told it was approx 9.5 to one compression.

He is going to get measurements how deep in the hole and the bore.

It also has a "purple cam" 429/444

Opinions on this 318 vs the one I already bought (1985 date).

1985 318 I can keep/refresh and drop in my 84 Prospector.

Thanks for the input

I found a 1974 318.No heads or intake. Bore is .030 over, pistons have 4 valve reliefs. Seller sounds honest. It was in his Duster(340 car)

He didn't do the "work" on the engine but was told to only run it on 93 octane and was told it was approx 9.5 to one compression.

He is going to get measurements how deep in the hole and the bore.

It also has a "purple cam" 429/444

Opinions on this 318 vs the one I already bought (1985 date).

1985 318 I can keep/refresh and drop in my 84 Prospector.

Thanks for the input

Mullinax , WELCOME BACK....It's good to be back with you numb skulls..... lol

I have started tinkering with my cuda again and needed yalls advise. Replacing the top end on my 360. Been PMing some members on here to get much needed advise.

You need to read this.... just so you won't run into problems. I wished I had read this before I put together my 360 because I had problems with my heads sucking in oil from the lifter valley.

INTAKE SEALING

I'm going to do this procedure with the new intake and the Eddy heads just to make sure the mating surfaces are correct.

mullinax95

Well-Known Member

So another option.

I found a 1974 318.No heads or intake. Bore is .030 over, pistons have 4 valve reliefs. Seller sounds honest. It was in his Duster(340 car)

He didn't do the "work" on the engine but was told to only run it on 93 octane and was told it was approx 9.5 to one compression.

He is going to get measurements how deep in the hole and the bore.

It also has a "purple cam" 429/444

Opinions on this 318 vs the one I already bought (1985 date).

1985 318 I can keep/refresh and drop in my 84 Prospector.

Thanks for the input

You say you found a 360?

I just about made up my mind that everything needs to run on 93 octane. No matter the compression ratio. The gas we get now days sucks.... sucks really bad. Talked to a self employed mechanic who has been doing mechanic work for like 50 years. He said he runs 93 in every engine he has... even his lawnmower and weed eater. My dodge ram likes the 93 better than the 87. However my Triumph Rocket III Roadster doesn't like 93 but likes 87... strange. I think the compression of the bike is 8.5. I do remember it is in the 8s. I'm sure there are other factors involved.

4spdragtop

Well-Known Member

No 360 lol. Alrho I will be tackling the 360 in my 84 Prospector.

Maybe the 1st 318 I bought will go in the truck.

I read on fabo where factory compression for 2bl 273 was 8.8:1?

Just wondering if the 85 318 I bought is worth putting in vs 74 .030 318 (with valve reliefs)?

Maybe the 1st 318 I bought will go in the truck.

I read on fabo where factory compression for 2bl 273 was 8.8:1?

Just wondering if the 85 318 I bought is worth putting in vs 74 .030 318 (with valve reliefs)?

You say you found a 360?

I just about made up my mind that everything needs to run on 93 octane. No matter the compression ratio. The gas we get now days sucks.... sucks really bad. Talked to a self employed mechanic who has been doing mechanic work for like 50 years. He said he runs 93 in every engine he has... even his lawnmower and weed eater. My dodge ram likes the 93 better than the 87. However my Triumph Rocket III Roadster doesn't like 93 but likes 87... strange. I think the compression of the bike is 8.5. I do remember it is in the 8s. I'm sure there are other factors involved.

nm9stheham

Well-Known Member

If these are the standard 4 valve relief pistons for a 318 (the only ones I can think of that have 4 valve reliefs), they'll be down in the hole about .075-.080, and then even with 273 closed chamber heads milled down to the NHRA minimum 57 cc chambers, and a .028" head gasket, the Static CR would be 8.4 LOL. So the only way it would be 9.5 static CR would be if the block was decked a LOT, AND the head chambers were small AND the head gasket were thin. Those 4 valve reliefs add 8-10 cc's of displacement per hole by themselves.So another option.

I found a 1974 318.No heads or intake. Bore is .030 over, pistons have 4 valve reliefs. Seller sounds honest. It was in his Duster(340 car)

He didn't do the "work" on the engine but was told to only run it on 93 octane and was told it was approx 9.5 to one compression.

He is going to get measurements how deep in the hole and the bore.

It also has a "purple cam" 429/444

Opinions on this 318 vs the one I already bought (1985 date).

1985 318 I can keep/refresh and drop in my 84 Prospector.

Thanks for the input

Sorry, but this story and seller sounds fishy, or at best, just not knowledgeable; this sounds like a standard, low compression rebuilt 318 short block. I would not simply take his word for the 'down in the hole' measurement. How will he measure the piston-to-deck height.... with a wooden kindergarten ruler?

4spdragtop

Well-Known Member

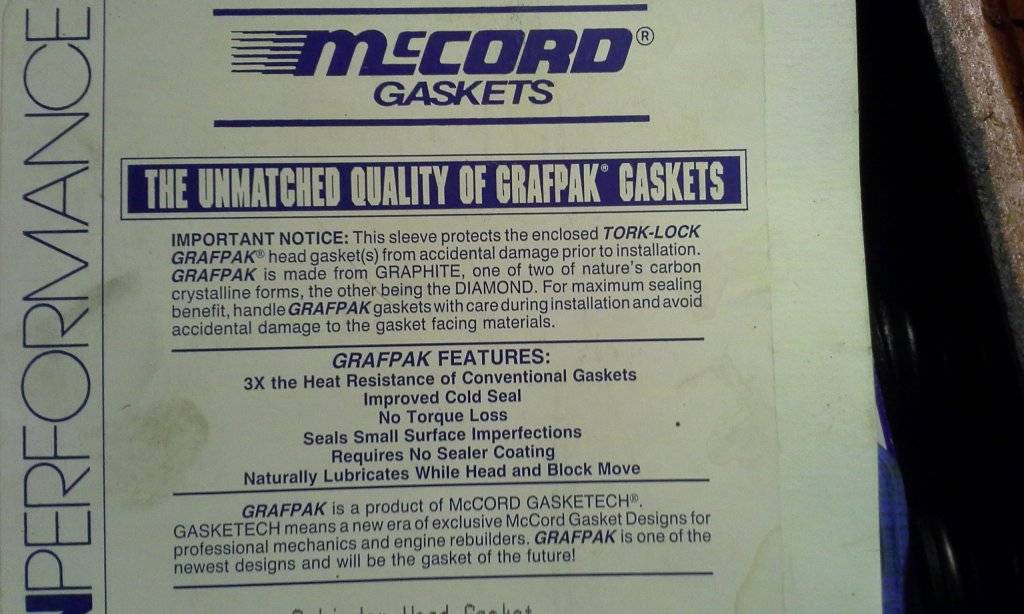

I got to look at the Mccord head gaskets. They are new and measured .0460" thick

[QUOTE="nm9stheham,

[QUOTE="nm9stheham,

How about pull the McCord head gaskets out of the box and look at them? Put a caliper on them to see if they are thick, like .050" or more. If you are lucky, these will be stock shim gaskets. I'll be straight-up with you: I think it is penny foolish to use thick head gaskets and expecting this engine to be a lot better for torque. The originals were shim gaskets around .022 thick; going with .050" thick head gaskets is just one more torque killer. Even with a smaller cam, you still need to fight for CR with those low CR pistons. 1121G gaskets are only $23 each. [/QUOTE]

nm9stheham

Well-Known Member

Interesting.... I would venture to guess they will compress down a bit more... maybe low .040" range ?? Are they a composite material like a typical Felpro? I'd still go with the 1121G's....that's worth about .2 point in Static CR. Get a little here and a little there and it'll add up.

BTW, I just looked back at you teardown pix of the 318 and noticed the valves have some very deep 'dimples' in them. I am willing to bet that those dimples shown are worth about 3 extra cc's of displacement per hole; I have measured 2 cc's on some less drastically dimpled valves. If you are doing the 302's see if you can dig up some flat faced valves out of your stash and reduce the chamber volume that way...with around .1 to .15 in CR. A little here, a little there.....every trick adds up.

BTW, I just looked back at you teardown pix of the 318 and noticed the valves have some very deep 'dimples' in them. I am willing to bet that those dimples shown are worth about 3 extra cc's of displacement per hole; I have measured 2 cc's on some less drastically dimpled valves. If you are doing the 302's see if you can dig up some flat faced valves out of your stash and reduce the chamber volume that way...with around .1 to .15 in CR. A little here, a little there.....every trick adds up.

4spdragtop

Well-Known Member

Good point on the dimpled valves. I would think the head gaskets will compress to .040".

I will chk on the material of them.

I also have located another set of 302 heads "ready to run". I will know more about them tonight. Apparently the intake ports were opened up a bit and gasket matched to work with a 360 intake. We will see how much they are opened up

Thanks again for the replies/advice I do appreciate it. Some is sinking in lol

I will chk on the material of them.

I also have located another set of 302 heads "ready to run". I will know more about them tonight. Apparently the intake ports were opened up a bit and gasket matched to work with a 360 intake. We will see how much they are opened up

Thanks again for the replies/advice I do appreciate it. Some is sinking in lol

Interesting.... I would venture to guess they will compress down a bit more... maybe low .040" range ?? Are they a composite material like a typical Felpro? I'd still go with the 1121G's....that's worth about .2 point in Static CR. Get a little here and a little there and it'll add up.

BTW, I just looked back at you teardown pix of the 318 and noticed the valves have some very deep 'dimples' in them. I am willing to bet that those dimples shown are worth about 3 extra cc's of displacement per hole; I have measured 2 cc's on some less drastically dimpled valves. If you are doing the 302's see if you can dig up some flat faced valves out of your stash and reduce the chamber volume that way...with around .1 to .15 in CR. A little here, a little there.....every trick adds up.

4spdragtop

Well-Known Member

Made from graphite.

4spdragtop

Well-Known Member

So more info on #2 318

Measured 3 holes. Average depth in hole was .0470" below deck.

Believe these are TRW pistons for 67-70 318. Advertised compression is 9.2 when used with 69cc heads and .039 thick gasket.

The guy sounds helpful/knowledgeable I hope to get a look at it this week.

Measured 3 holes. Average depth in hole was .0470" below deck.

Believe these are TRW pistons for 67-70 318. Advertised compression is 9.2 when used with 69cc heads and .039 thick gasket.

The guy sounds helpful/knowledgeable I hope to get a look at it this week.

I was just asking Calvin about you a week ago. Where have you been?I vote 318 with 302 heads (milled down to bump up compression) with the 273 adjustable valve train. Don't forget to plug the smog ports on the 302 heads.

65cuda340

Well-Known Member

Since you mentioned that you are considering other options, I have a '68 340 available. I just honed the cylinders when I built it in 1975, so first oversize is still available. It has not been cranked since it was pulled out of my car almost two years ago, and after 40 years since the rebuild you would certainly want to go through it again. All stock internals except it has the old purple shaft cam, Crane lifters, double roller timing chain, and high volume oil pump. Stock "X" heads. Crank has been turned .010" undersize. Direct Connection electronic distributor, but that is also 40 years old. I have the stock cast iron 4 barrel manifold, but it is not installed on the engine. Everything is currently in Chicago if you are interested.

mullinax95

Well-Known Member

I was just asking Calvin about you a week ago. Where have you been?

I don't want to hi-jack 4spdragtop's thread....so I'll keep short... I've been busy with riding my Triumph motorcycle .... whirl wind of other stuff.

nm9stheham

Well-Known Member

Just keep repeating..... "I need more CR.... I need more CR..." LOL

Buuut, I compute 8.25 SCR with:

- 8 cc in 4 valve reliefs total

- .047 below the deck

- 64 cc head chambers with your 302 heads

If the 4 valve reliefs have only 4 cc's total displacement volume, then SCR is 8.6.

So much for 'advertised' compression... for 8 cc valve reliefs, it bumps up to 8.45 with the the .028 head gasket, and is 8.55 with the old .022 shim head gasket.

So you are in the low to mid 8's, it looks like...I wonder if his block was decked....

Well that would be better (I hope I AM wrong on this guy.) Clean/Scrape off a piston top and see if you find an Lxxxxy number on the top; the Lxxxx was standard TRW-ese. F in the 'y' position is for forged...I can't recall what the suffix was for cast.So more info on #2 318

Measured 3 holes. Average depth in hole was .0470" below deck.

Believe these are TRW pistons for 67-70 318. Advertised compression is 9.2 when used with 69cc heads and .039 thick gasket.

The guy sounds helpful/knowledgeable I hope to get a look at it this week.

Buuut, I compute 8.25 SCR with:

- 8 cc in 4 valve reliefs total

- .047 below the deck

- 64 cc head chambers with your 302 heads

If the 4 valve reliefs have only 4 cc's total displacement volume, then SCR is 8.6.

So much for 'advertised' compression... for 8 cc valve reliefs, it bumps up to 8.45 with the the .028 head gasket, and is 8.55 with the old .022 shim head gasket.

So you are in the low to mid 8's, it looks like...I wonder if his block was decked....

Last edited:

Hi all, looking for some guidance here. May be a little long winded here, with lots of questions lol. Like the title states Im looking at a budget build involving(possibly) above components.

This is going in dads 67 cuda, factory S fastback with factory 904 3:23 SG and 8 3/4.

For engine right now it has a 66 date code 273. Originally a 2bl engine, so pistons are low compression. Factory adjustable valve train.

When dad bought the car we installed a comp cams kit #CL20-246-4 and upgraded to the double roller timing chain set. New cam bearings. We also topped it with Eddy 1406, then added an elec choke. It has MP elec ignition.

Factory 273 exhaust manifolds.

Sounds and idles great, oil psi good(approx 45-50 at idle) but did not have the power low end I thought it would.

Unsure of what stall the torque converter is. I know I had to grind a weight off of it as per recommendations. 360 converter maybe?

Last year I removed factory heads with comp springs and retainers. I stripped them down, sandblasted, relapped valves and did a diy "port" job.

Reinstalled heads and added an LD4B.

Still not much in low end power, but its been a reliable motor since dad n I put it together in 2012. Probably around 10-12,000 miles since then.

Im unsure of where timing is at and rods and jets in carb are orig Eddy spec.

I believe that I have over cammed the 273 due to the low comp pistons

My plan is to drop in a budget build respectable small block using as much as what I have and still have the swap done in the course of a weekend. Hoping to add maybe 50 HP??

What I bought was an 87(I think) 318, I was hoping for the 302 casting heads, but came with heads #4027163. But it did come with LD340 and Eddy 1405 and brand new oil pan. Compression test was over 120(using a lousy battery, and engine was out of vehicle, so we stopped at 120). All plugs removed and WOT. No disassembly has begun yet so unsure of pistons, bottom end.

I continued my search for heads and have located 2 sets of 302 heads. 1 is bare and 3 are loaded. Machine shop magnafluxed bare one and came back no cracks.

3 loaded ones I brought home to disassemble and then have them magnafluxed.

I am hoping to be able to strip down the 87 318, use 302 heads, which will bump compression a little bit. Then there is the option of intake. I have an LD4B unmodded currently on 273. I also have the LD340 that came on the 87 318. LD340 can wait for my 340 build for my 69 ragtop(whenever I get to it lol)

Heres list of parts on hand and hope to use most of these to keep costs down(if 302's need machining it gets pricey!)

On hand

-runnning 66 273 2bl pistons, Eddy 1406, LD4B, factory manifolds, adjustable valve train

Comp cams 270-s cam and lifters(10-12,000 miles)

-LD340

-complete 340 x heads

-factory iron 273 4bl intake

-factory iron 70 340 intake

-68-70 HP 340 exhaust manifolds.

-302 heads

-complete 87 318

-set of 4027163 318/360 heads

Would stock 273 adjustable valve train work on 302 heads? Also whats the opinion of using the complete Comp Cams kit from the 273 and installing in 318? Is that cam an overkill even for the 318 with 302 heads?

If 302 heads come back good, Im open to do the DIY cleanup/port job as well.

Combinations/advice?

Thanks all

Steve

View attachment 1715035617

View attachment 1715035620

View attachment 1715035621

View attachment 1715035622

View attachment 1715035623

Would this head gasket have been more helpful for you?

https://www.summitracing.com/parts/mrg-1121g/overview/make/plymouth

4spdragtop

Well-Known Member

Thanks, it may be thinner than the one I used on the 273 I used Felpro, can't remember which one.

Im not sure whether I will use this 85 318 in the cuda or not. At worst I will put in my 84 1/2 ton.

Thanks

Steve

Im not sure whether I will use this 85 318 in the cuda or not. At worst I will put in my 84 1/2 ton.

Thanks

Steve

Would this head gasket have been more helpful for you?

https://www.summitracing.com/parts/mrg-1121g/overview/make/plymouth

Then u know what to do. Put the 318 back together witha re-ring kit. Install in truck. 360 has a new home. Kim

-