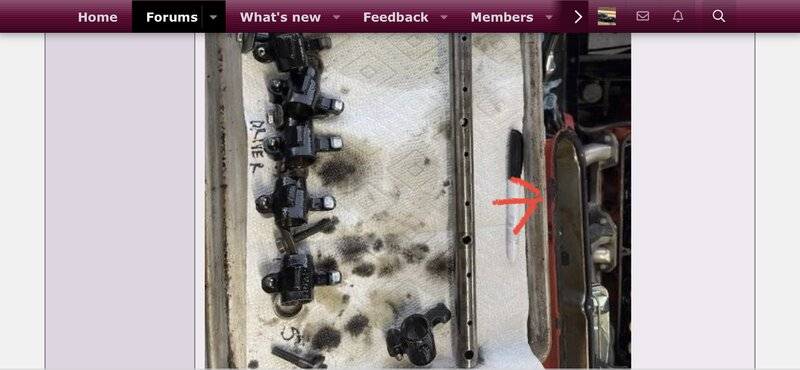

Moving forward. I have the driver side pulled. I can use some inspection and cleaning advice here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 Oil Priming Question First Start

- Thread starter 340inabbody

- Start date

-

Looks like Chrysler is no longer making the rocker shaft end freeze plugs. Mancini is out Year One out the dealerships are out. Nobody has them…..Moving forward. I have the driver side pulled. I can use some inspection and cleaning advice here.

View attachment 1716250114

When the oil hole was lined up, did you try putting the rocker shaft back on and letting the primer run for a bit?Looks like Chrysler is no longer making the rocker shaft end freeze plugs. Mancini is out Year One out the dealerships are out. Nobody has them…..

Doing that now. I just thought about that too! They looked clean.When the oil hole was lined up, did you try putting the rocker shaft back on and letting the primer run for a bit?

For the alignment the shaft small holes face down towards the motor right?

Inertia

Well-Known Member

Looks like Chrysler is no longer making the rocker shaft end freeze plugs. Mancini is out Year One out the dealerships are out. Nobody has them…..

Most auto parts stores will have a multi-compartment box behind the counter with both US and metric plugs.

If you drilled a hole in the plug to remove it, braze/weld the hole, or put the screw back in.

Or just leave the whole thing alone, you have oil to the top, you always did, (put the 2 bolts back in), put valve cover back on and drive it.

Last edited:

I did check for rocker shaft assembly orientation. The passenger end groove is in front pointing inward. See first pic....

View attachment 1716250108

View attachment 1716250109

So, as a minimum, the passenger side shaft appears to be installed incorrectly as the notch should be in the back.

Your right! The shaft is the wrong way. Can Should I reverse the shaft and maintain the rocker positions/orientations?So, as a minimum, the passenger side shaft appears to be installed incorrectly as the notch should be in the back.

After very careful inspection I found a very low relief notch in the driver shaft towards the front pointing to the engine centerline as the fsm states it should. See pic

Last edited:

TT5.9mag

Two atmospheres are better than one

YesShould I reverse the shaft and maintain the rocker positions/orientations?

Summary:

1. Couldn’t get flow at rocker arms during manual priming of the oil pump.

2. 60 psi was held continuously through slow crank rotation.

3. #2 and #4 rocker bolts removed and confirmed high volume flow on each side.

4. Passenger rocker shaft was reversed.

Update:

1. With the crank centered for high volume flow on the driver side (shaft not reversed) assembly torqued down and 60psi applied…no flow out most of the rockers but a small dribble out two or three.

Note: The driver side rocker shaft orientation notch is very faint and not prominent like on the reversed passenger side.

Tomorrow I plan to reverse the passenger rocker and reorient it correctly and see if I get flow that side.

Any other inputs are appreciated!

Thanks!!

1. Couldn’t get flow at rocker arms during manual priming of the oil pump.

2. 60 psi was held continuously through slow crank rotation.

3. #2 and #4 rocker bolts removed and confirmed high volume flow on each side.

4. Passenger rocker shaft was reversed.

Update:

1. With the crank centered for high volume flow on the driver side (shaft not reversed) assembly torqued down and 60psi applied…no flow out most of the rockers but a small dribble out two or three.

Note: The driver side rocker shaft orientation notch is very faint and not prominent like on the reversed passenger side.

Tomorrow I plan to reverse the passenger rocker and reorient it correctly and see if I get flow that side.

Any other inputs are appreciated!

Thanks!!

I would be surprised if the rocker shafts themselves are clogged. You could probe the mounting holes with electrical wire and carb cleaner to see if anything is in there. You can check the shaft exit oiling holes by removing the rockers and taking a look. You should carb cleaner the rockers thoroughly and inspect the oil exit holes for any clogs. Oil it all up and put it back together. It should oil.

I'll also add that I have always looked for the location where oil shoots up to the shaft. Keep the oil pump turning at that location and you should see oil exiting each rocker somewhere even if not so much at the top.

BTW, what rockers are you running? Are they 273 adjustable rockers with a flat tappet cam? I remember running a 273 with the valve covers off in an attempt to adjust valve lash while running. Not good. Oil got everywhere and made a mess. : )

BTW, what rockers are you running? Are they 273 adjustable rockers with a flat tappet cam? I remember running a 273 with the valve covers off in an attempt to adjust valve lash while running. Not good. Oil got everywhere and made a mess. : )

4spdragtop

Well-Known Member

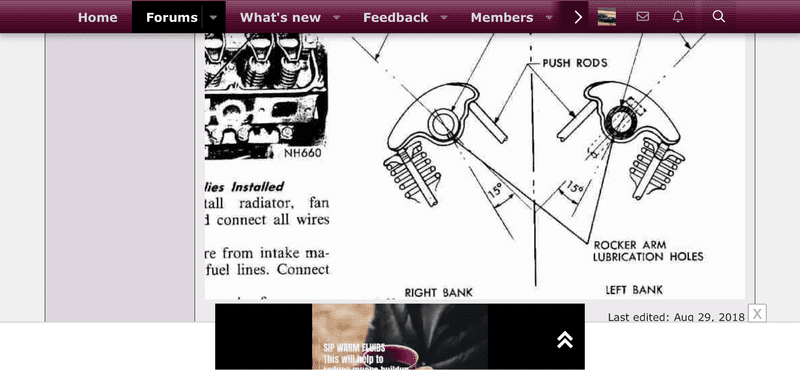

Some info, might help?

Camshaft oil timing to shafts

Camshaft oil timing to shafts

Hey I have no background info on this motor. I bought it as is. I don’t know what cam is in it but I did bore scope the cylinders and found 0.030 over TRW 12:1 slugs with what looked like clean tops and the walls looked good. It ran when I started work on the body.I'll also add that I have always looked for the location where oil shoots up to the shaft. Keep the oil pump turning at that location and you should see oil exiting each rocker somewhere even if not so much at the top.

BTW, what rockers are you running? Are they 273 adjustable rockers with a flat tappet cam? I remember running a 273 with the valve covers off in an attempt to adjust valve lash while running. Not good. Oil got everywhere and made a mess. : )

This is a flat tappet set up. Is there a way to identify the rockers and make sure they are properly clearanced

for oil flow? I plan to take them apart and clean them in the morning.

Ps I did see a little oil coming from under the rocker maybe not on all and not so much….

Last edited:

TT5.9mag

Two atmospheres are better than one

Those are 273 adjustable iron rockers. That’s a good rocker and about perfect for your application. There are two oil holes in them and you want to run a wire through each one to make sure they’re clear. Then do all the holes in the shaft.

@Dicer nailed it about the oil flow out of the top holes on the rockers. You will get very little. Just enough to drool down the rocker and lube the valve stems and rocker pads.

On the rocker shaft installation. Here's how they install. Passenger's side, the notch in the end goes to the REAR and DOWN. On the driver's side the notch goes to the FRONT and DOWN. Driver's side appears to be correct.

On the rocker shaft installation. Here's how they install. Passenger's side, the notch in the end goes to the REAR and DOWN. On the driver's side the notch goes to the FRONT and DOWN. Driver's side appears to be correct.

4spdragtop

Well-Known Member

Better shot of end of shaft?

Hey I have no background info on this motor. I bought it as is. I don’t know what cam is in it but I did bore scope the cylinders and found 0.030 over TRW 12:1 slugs with what looked like clean tops and the walls looked good. It ran when I started work on the body.

This is a flat tappet set up. Is there a way to identify the rockers and make sure they are properly clearanced

for oil flow? I plan to take them apart and clean them in the morning.

Ps I did see a little oil coming from under the rocker maybe not on all and not so much….

View attachment 1716250280

View attachment 1716250281

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,611

- Reaction score

- 2,345

So, a note of caution, when you put it back together. Make sure the pushrods are seated in the center of the lifter. Due to the small blocks crazy lifter angle, you can have the pushrod sitting were the lifter body and plunger meet. Off center, that can hold the valve open or it reduces your piston to valve clearance. You can look through the opening and see that the pushrod is center. I look at every one! It will scare the crap out of you when it SNAPS into place! Don’t ask me how I know…… Also if one adjuster is way different from the others. REALLY look at that one.

Also if one adjuster is way different from the others. REALLY look at that one.

Driver side front of shaft. Rear is completely smooth. It’s faint but it’s definitely the right size but not a notch more like an imprint.Better shot of end of shaft?

So I have removed the shaft and inspecting it. Are the rockers compatible with this rod? The rockers have teo small holes. Do the small lifter holes have to align with the hole on the shaft at some point to get flow? Does this all look right?

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,611

- Reaction score

- 2,345

So you see how the bolt holes are not inline with the oil holes? You want the oil holes down and more towards the valve springs.

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,611

- Reaction score

- 2,345

Remember the shaft is upside down in the picture, but the arrow points to valve springs.

The rocker adjusters seem to be all over the place adjustment wise. They also seem awful close to touching the spring retainers. Just an observation.

When I installed the shaft I did it with the alignment notch pointing towards the center of the motor for the driver side notch in front. Then I verified all the oiling holes pointing down. There is nothing else I can do with respect to geometry or alignment…..So you see how the bolt holes are not inline with the oil holes? You want the oil holes down and more towards the valve springs.

View attachment 1716250554

furrystump

Well-Known Member

- Joined

- Nov 13, 2004

- Messages

- 2,611

- Reaction score

- 2,345

The notches are an indicator of the location of the oil holes. Know the orientation of the oil holes themselves and you KNOW they are correct. If the oil holes are down and biased towards the springs they are correct. You don’t have to worry if your notch is a real notch or the notch was machine incorrectly or anything else, because you cut out the middleman and know where the oil holes actually are.

-