You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

69 Notch Barracuda - Rebirth

- Thread starter JCJones

- Start date

-

JCJones

Well-Known Member

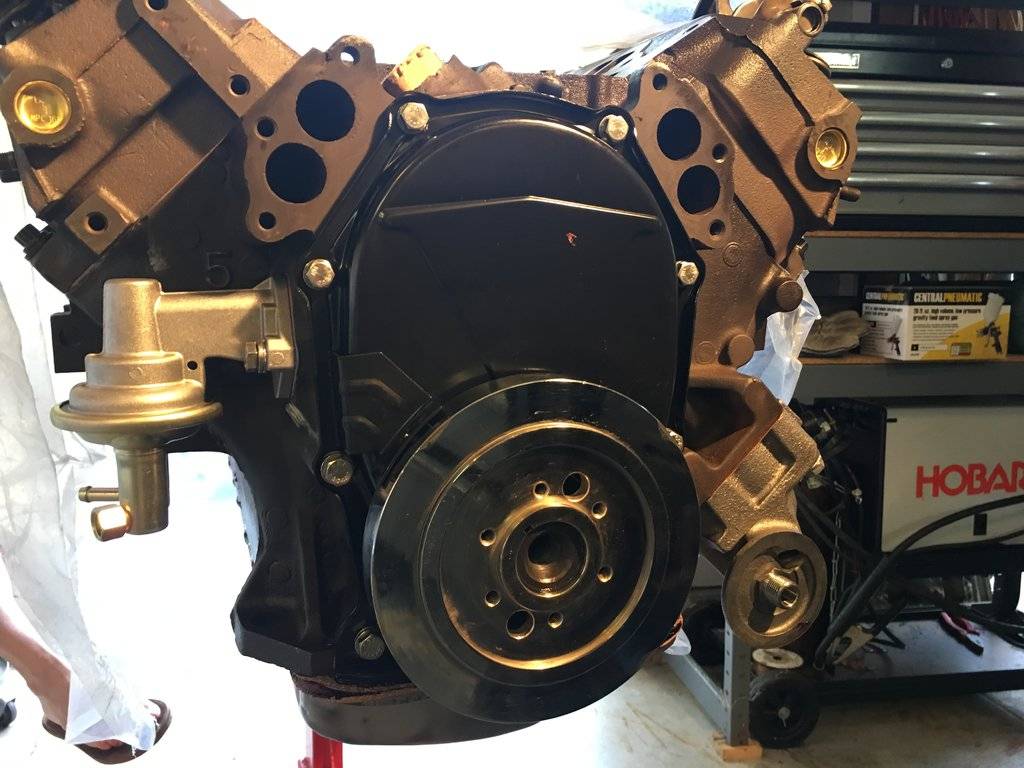

All ready to go..

JCJones

Well-Known Member

I decided that I want to go with a bare metal finish on my oil pan (purchased from another fabo member). I just love a tattered metal (brushed aluminum/wire wheel) look. So I searched around and found that people building 'rat rods' consider Gibbs Penetrating Lubricant to be the best of the best as far as keeping the rust from forming on their bare metal finishes. The best part is... if you decide you want to paint down the line, you can just paint right over it. Granted, I'm sure someone who produces Show Quality paint jobs wouldn't think of it, but that ain't me. Regardless, it can be cleaned off before paint.

JCJones

Well-Known Member

And the part I've been waiting to order for a long time… the Performer RPM.

Dude! you are charging it! Baddassery for sure!

4spdragtop

Well-Known Member

Great progress and documentation. You painting the block?

And the part I've been waiting to order for a long time… the Performer RPM.

View attachment 1715093289

I put the 440 version of that same intake on my car back in 2001. Between the block being decked, the heads being cleaned up and the intake the bolt holes for the intake did not even line up, it sat up too high. I ended up having to remove 0.110" from each face of the intake to get the ports to line up correctly. Just relaying this little tidbit in case you have not checked the alignment of the intake to the heads.

JCJones

Well-Known Member

Installed the harmonic balancer today. Holy god what an intense workout. I rented an installation kit and it was still a ton of work to crank it on. I did NOT use heat or freezer (next time I'll try that)... just lubed up the inside/outside of the balancer snout, as well as the threads of the installation tool and started cranking. Finally grabbed a big-arse pipe wrench (for the larger handle) toward the end when the muscles and tendons where giving out.

It seemed to bottom out, so that's when I stopped.

It seemed to bottom out, so that's when I stopped.

Yes... the intake alignment has totally been one of my worries. The deck and heads have been milled, so thanks for the reminder. I already installed the heads and torqued them down.

Hopefully I'll be able to do any milling on the intake without removing the heads?

Damn that's a purdy powerplant you have there!

The intake gets cut, so no worries, the heads stay on. Thanks, but that was the engine in 2001, it has a different set of heads and a new intake now:

JCJones

Well-Known Member

I realize now that I probably should have circled the entire bolt hole on the end rails under the valley pan, but I was trying to minimize the amount of RTV that could make its way inside the block. I'll do some cleaning and seal the bolt heads from the top to try and stop any oil seepage that may come up through the bolt hole. It's possible that enough of the RTV squished around the opening, but damn, this is one of those little details that will nag at me for a while.

JCJones

Well-Known Member

Great build man. I with you on function over ridiculous shiny cars. I like your style.

Hey, thanks a lot my friend.

I realize now that I probably should have circled the entire bolt hole on the end rails under the valley pan, but I was trying to minimize the amount of RTV that could make its way inside the block. I'll do some cleaning and seal the bolt heads from the top to try and stop any oil seepage that may come up through the bolt hole. It's possible that enough of the RTV squished around the opening, but damn, this is one of those little details that will nag at me for a while.

Those holes are blind, you should not have any problem.

JCJones

Well-Known Member

Last edited:

JCJones

Well-Known Member

Carb all rebuilt and lubed.

MrJLR

Built, not bought

Making real progress!!!

Jeff

Jeff

my68barracuda

Well-Known Member

Are you considering bending replacement brake lines? Asking as I saw your question concerning the wire armor on the bends,, before you bend your own, check out replacement brake line sets from Inline tube,, I put their replacement brake lines on two vehicles,, they fit great. Inline also has the distribution block.

Last edited:

JCJones

Well-Known Member

...

JCJones

Well-Known Member

I had to use an air hammer to get he pistons out. The inner walls look very smooth, so I decided to stick with the originals for Now.

Also... all of my old brake lines are pretty pristine. I only changed them for peace of mind. I’m assuming there is no resale value in fifty year old brake lines?

Also... all of my old brake lines are pretty pristine. I only changed them for peace of mind. I’m assuming there is no resale value in fifty year old brake lines?

MrJLR

Built, not bought

EVERY darn time I've rebuilt calipers they leaked....I gave up and just buy new ones....LOL

Looking good!

Jeff

Looking good!

Jeff

MrJLR

Built, not bought

The good news is they not "terribly" expensive!Good to know! This is my worry as well.

Jeff

4spdragtop

Well-Known Member

Nice work. Stupid as it sounds there was a thread on here for flaring. I've done it for year's and found it informative. I think it mentioned "filing" the edges?

Keep up the good work.

Keep up the good work.

Nice work!

moparmat2000

Well-Known Member

The wire that wraps the brake line is called gravel guard. Like the name implys it protects the tubing from a kicked up rock from the tire that might damage or puncture the brake line. Some brakeline places sell the coiled wire ready to go to slide over your brake tubing if your bending and flairing your own. I believe inline tube sells the gravel guard by itself. Cheap too i think a 20' long roll of it is $25Started breaking down and inventorying the replacement parts for the brake system. I'll be running all new lines, fittings, master cylinder, new rubber lines, etc. what a beast of a job to unbolt the MC plunger from the brake lever. Very little room to fit wrenches up underneath the steering column!

Anybody know if the wire that wraps the tight bends is necessary?

View attachment 1715114984

View attachment 1715114985

Last edited:

-

Similar threads

- Replies

- 1

- Views

- 155

- Locked

- Replies

- 0

- Views

- 318

- Locked

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 499