You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

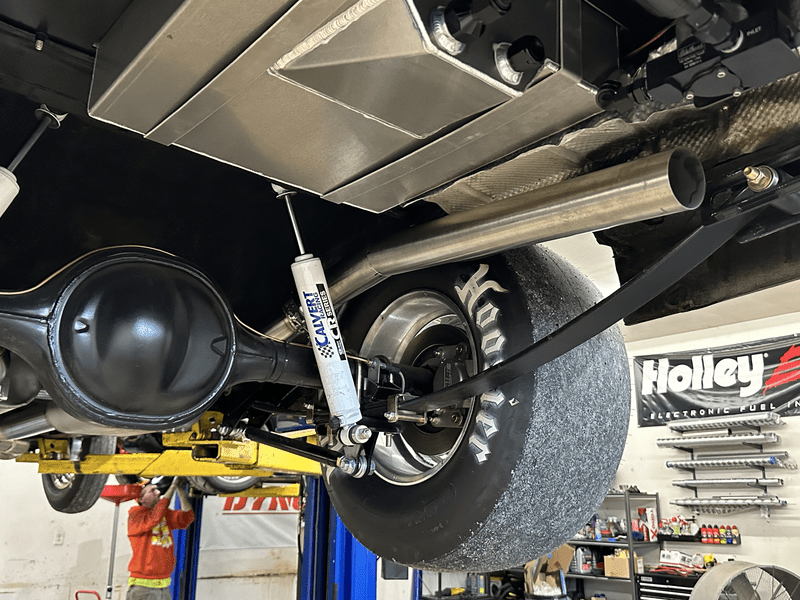

70 dart 470 ci drag car build.

- Thread starter MOPARMAGA

- Start date

-

10 gallons

Street car size. Lol

As usual things take way longer than I wish they would but I'm really trying to make a nice car.

This is my fuel cell frame, great plan until I noticed I couldn't get fuel lines on lol, so I fixed that. I made some .125 tabs that I will weld nuts too on the underside of the car for when I'm 90 years old (thank myself).

View attachment 1716223011

View attachment 1716223012

View attachment 1716223020

View attachment 1716223021

View attachment 1716223032

Hopefully I put it in a good spot.

Ask Shadow how you did. He's in full supervisor mode right now. He won't lie to you. The wife?? They all lie to us. But Shadow won't lie.

Yeah that was just in case but I might need to run it full depending on how the weight bias is.Street car size. Lol

Shadow is very proud of his daddy.Ask Shadow how you did. He's in full supervisor mode right now. He won't lie to you. The wife?? They all lie to us. But Shadow won't lie.

Shadow is very proud of his daddy.

One day soon you'll have Popcorn out there to supervise. Once he's out there you won't be able to get away with dang thing with his big, hairy *** watching your every move.

Yep he will definitely willOne day soon you'll have Popcorn out there to supervise. Once he's out there you won't be able to get away with dang thing with his big, hairy *** watching your every move.

-Boosted-

Hard Member

Looking good but why are you adding so much weight to the car? My fuel cell is held in place with aluminum straps that weight less than a pound total.... lol

Simple answer I have steel, I don't have money for aluminum.Looking good but why are you adding so much weight to the car? My fuel cell is held in place with aluminum straps that weight less than a pound total.... lol

View attachment 1716223127

I also wanted one more cross member in the back.

Not to mention I'm going to be hitting the tires at around 650 ft lbs of torque, id like to hook lol.

Also I like building stuff.

-Boosted-

Hard Member

I get it.Simple answer I have steel, I don't have money for aluminum.

I also wanted one more cross member in the back.

Not to mention I'm going to be hitting the tires at around 650 ft lbs of torque, id like to hook lol.

Also I like building stuff.

I didn't get a hole lot done today.

Lol Since Bill was mean to me about making my car heavy I had to go find so weight to remove from the trunk. Now my fuel cell frame is -2 pounds.

I was going to drill some holes in that frame but my stupid 1/4 inch pilot drill bit bent at some point and was wobbling, I sez f it... Good enough.

Then I cleaned up paint and rust , cut stuff out & made some trunk floor panels.

I did my "okay" best on it .

Drill holes for spot welds.... yeah 160 of them lol

Lol Since Bill was mean to me about making my car heavy I had to go find so weight to remove from the trunk. Now my fuel cell frame is -2 pounds.

I was going to drill some holes in that frame but my stupid 1/4 inch pilot drill bit bent at some point and was wobbling, I sez f it... Good enough.

Then I cleaned up paint and rust , cut stuff out & made some trunk floor panels.

I did my "okay" best on it .

Drill holes for spot welds.... yeah 160 of them lol

-Boosted-

Hard Member

Since Bill was mean to me about making my car heavy I had to go find so weight to remove from the trunk.

I'd tell Tim. lolSince Bill was mean to me

I just learned a very crappy lesson.

My spot weld holes are too big and I'm burning my new metal.

My mig won't work well in the lowest setting.

I have the wire speed up max and on the 2nd setting it's an .035 wire only millermatic 35

Piss me off.

I'll fix it or just put some light weight carpet in.

From now on I'm using a 1/16 drill bit.

My spot weld holes are too big and I'm burning my new metal.

My mig won't work well in the lowest setting.

I have the wire speed up max and on the 2nd setting it's an .035 wire only millermatic 35

Piss me off.

I'll fix it or just put some light weight carpet in.

From now on I'm using a 1/16 drill bit.

He'd just laugh at me & be mean too lolI'd tell Tim. lol

Just don't let him off the leash, and don't feed him raw wild game. lolHe'd just laugh at me & be mean too lol

That's his wife's job....lolJust don't let him off the leash, and don't feed him raw wild game. lol

To keep him on a leash? I doubt that. but maybeThat's his wife's job....lol

She can't control what varmints he might encounter outside his shop. I hear there's a few coyote around. lol

He'd just laugh at me & be mean too lol

Step on his foot.

Snakes are probably popping out this week too.To keep him on a leash? I doubt that. but maybe

She can't control what varmints he might encounter outside his shop. I hear there's a few coyote around. lol

He hates the woodpecker that made a hole in his garage. Coyotes are out like bandits now

TT5.9mag

Two atmospheres are better than one

Ive found on my millermatic 211 and other small welders that the wire speed adds a percentage of voltage to the weld. Keep the power the same and turn your wire down and try it.I just learned a very crappy lesson.

My spot weld holes are too big and I'm burning my new metal.

My mig won't work well in the lowest setting.

I have the wire speed up max and on the 2nd setting it's an .035 wire only millermatic 35

Piss me off.

I'll fix it or just put some light weight carpet in.

From now on I'm using a 1/16 drill bit.

Edited to add, from weldingweb forums;

Wire speed tracking is where the wire speed increases or decreases as VOLTAGE control is increased or decreased in order to help the operator stay within the weld parameters when making voltage changes.

Last edited:

Hey thanks, that's worth a try for sure !Ive found on my millermatic 211 and other small welders that the wire speed adds a percentage of voltage to the weld. Keep the power the same and turn your wire down and try it.

Edited to add, from weldingweb forums;

Wire speed tracking is where the wire speed increases or decreases as VOLTAGE control is increased or decreased in order to help the operator stay within the weld parameters when making voltage changes.

ValiantS

Well-Known Member

Are you going to gusset the sliders at the overhang on the framerails?I didn't get a hole lot done today.

Lol Since Bill was mean to me about making my car heavy I had to go find so weight to remove from the trunk. Now my fuel cell frame is -2 pounds.

I was going to drill some holes in that frame but my stupid 1/4 inch pilot drill bit bent at some point and was wobbling, I sez f it... Good enough.

Then I cleaned up paint and rust , cut stuff out & made some trunk floor panels.

I did my "okay" best on it .

Drill holes for spot welds.... yeah 160 of them lol

View attachment 1716223591

View attachment 1716223592

View attachment 1716223593

ValiantS

Well-Known Member

For those areas you could try a strip of metal as filler if it's easier to 'repair'. 1/16 is pretty standard because you can cleko pin/fit the sheet metal.I just learned a very crappy lesson.

My spot weld holes are too big and I'm burning my new metal.

My mig won't work well in the lowest setting.

I have the wire speed up max and on the 2nd setting it's an .035 wire only millermatic 35

Piss me off.

I'll fix it or just put some light weight carpet in.

From now on I'm using a 1/16 drill bit.

-

Similar threads

- Replies

- 9

- Views

- 378

- Replies

- 10

- Views

- 1K

- Locked

- Replies

- 0

- Views

- 301

- Replies

- 1

- Views

- 2K