You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

71 Duster 360 turbo build

- Thread starter turbovan

- Start date

-

I’m still so impressed with the intercooler setup behind the dash. Everything is looking great!

Thank you both! I love how the intercooler worked out, and it was not a difficult project. I certainly believe I have too much fuel, and planned it that way. Supply side is 1/2” 8an, and return is 3/8” 6an.

Does anyone know if the loops in the brake lines coming off the master cylinder are necessary? I’m not too fond of them.

Does anyone know if the loops in the brake lines coming off the master cylinder are necessary? I’m not too fond of them.

Fuel pumps wired and everything pressure tested. Things really came together today and the car fired up on the first turn of the key! New setup runs fantastic(in the driveway). If I knew it would be that easy I wouldn’t have wasted my time firing it on the bad engine.

Next week I’ll pull the engine and send the converter out to drop the stall 1k rpm. Head studs showed up out of nowhere so things are coming together! Also picked up paint for the engine bay today so I’ll get that prepped and painted while the motor is out.

View attachment 1715972125

Next week I’ll pull the engine and send the converter out to drop the stall 1k rpm. Head studs showed up out of nowhere so things are coming together! Also picked up paint for the engine bay today so I’ll get that prepped and painted while the motor is out.

View attachment 1715972125

Finished painting the engine bay today and pretty happy with how it turned out(first time). Rebuilt the steering column and installed a new coupler to help with clearance. Built inner fender braces with angle iron that seem pretty sturdy, and hopefully they’re effective. Reinforced and seam welded the K frame, and built a radiator support brace to further stiffen the front end.

turbodart68

Well-Known Member

Looks great!

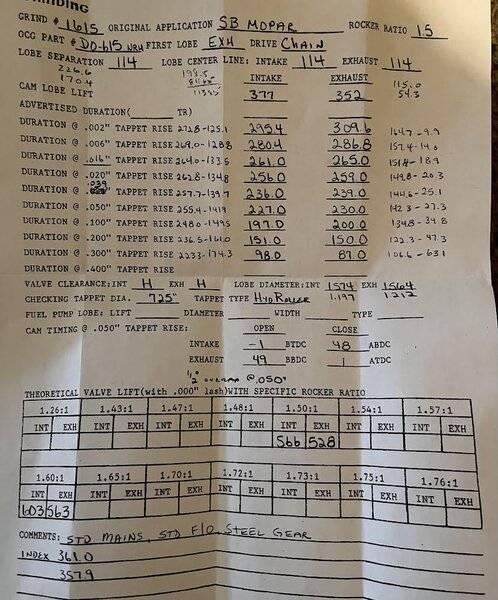

I was able to finish assembling the shortblock yesterday, and expect to have the rest together in the next couple days. I installed the cam 4° advanced, but I’m not positive that’s where I want it. I’m contemplating installing it straight up. I would like to make power up to 6500, but have little interest in spinning it higher than that. It has Elgin HL-2269S hydraulic roller lifters and they may not support that much rpm anyways.

I’m running prw 1.6 rockers with a B3 geometry correction kit

I’m running prw 1.6 rockers with a B3 geometry correction kit

Matts440

Well-Known Member

Do you have a degree wheel? Would utilize the power of the cam better.

Yes, and it’s currently degreed in with 4° advance; 110 ICL.Do you have a degree wheel? Would utilize the power of the cam better.

Matts440

Well-Known Member

Oh okay wasn't sure if you did. Should be able to pull 6500 pretty easy and have a good power band curve.Yes, and it’s currently degreed in with 4° advance; 110 ICL.

Ouch.Finished assembling the motor today. It’s my first time assembling a roller motor. I hope this thin metal thingy isn’t important…

View attachment 1716007844

View attachment 1716007845

Matts440

Well-Known Member

Looking awesome. I mounted mine just behind the front bumper mount. Trans cooler in in the rear due to no room in front.

I REALLY appreciate those pictures. My oil cooler is about the same size as yours, but I think there is a little less room behind the grill on dusters. I’ll look into that spot again tomorrow. I was also thinking about mounting it under the car just in front of the rear axle, but that’s more of a last resort spot.

Matts440

Well-Known Member

Anytime, not sure on the room on dusters, been a long time since I've been around one lol it took a bit to get in the right position, and I looked at different areas but hopefully you can make it work in front to help cool more then under the car.

Finished assembling the motor today. It’s my first time assembling a roller motor. I hope this thin metal thingy isn’t important…

View attachment 1716007845

I hope you are kidding about that spider if running OEM style lifters and dogbones. It's REALLY important with oem rollers

Oh I definitely forgot it, but I already pulled the intake to get it back home.I hope you are kidding about that spider if running OEM style lifters and dogbones. It's REALLY important with oem rollers

What are you running for boost control? Dual MAC valves? Did your GT45 come with a tapped hole for compressor discharge?

I’ll just be running off the wastegate spring for now, but will switch to a ball/spring boost controller when I want to turn it up. They bring boost in much harder so I’ll have to see how the tires handle it.

It did not have a hole so I tapped the back side of the compressor housing for a 1/8npt nipple. When I switch to the ball spring valve I’ll use manifold pressure.

It did not have a hole so I tapped the back side of the compressor housing for a 1/8npt nipple. When I switch to the ball spring valve I’ll use manifold pressure.

Last edited:

dusted

Well-Known Member

I drilled and tapped a hole also. Just ran the boost controller/adjuster straight off that.I’ll just be running off the wastegate spring for now, but will switch to a ball/spring boost controller when I want to turn it up. They bring boost in much harder so I’ll have to see how the tires handle it.

It did not have a hole so I tapped the back side of the compressor housing for a 1/8npt nipple. When I switch to the ball spring valve I’ll use manifold pressure.

-

Similar threads

- Replies

- 244

- Views

- 8K