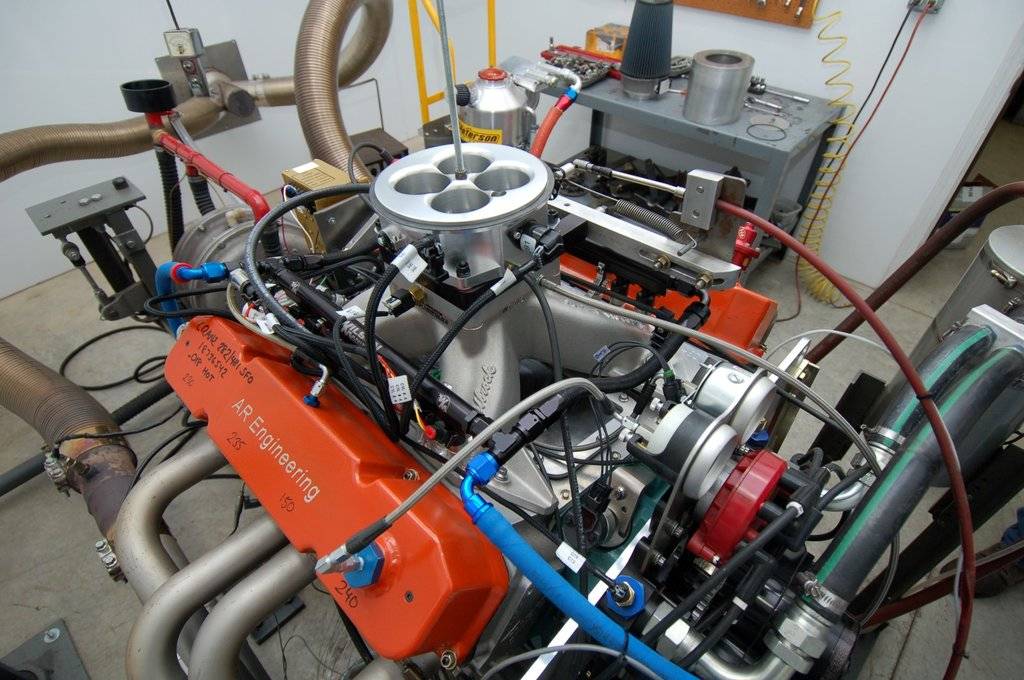

Just finished a couple days of dyno testing on this 514 inch big block with sequential EFI. Tuning has never been so easy! We just click the mouse to change the fuel curve or the ignition timing. I'm using the Holley HP system on this engine which allows me to change the fuel by cylinder if I want or to run all cylinders the same. The Holley system also has extensive data logging capability so we can playback all kinds of things from coolant temp, manifold vacuum, pan vacuum, fuel consumption, oil pressure, fuel pressure, etc.,etc. Tons of fun!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

900 hp big block with EFI

- Thread starter AndyF

- Start date

-

GeorgeH

Well-Known Member

dadodgekid

When in doubt... floor it

Had my 514 inch big block on the dyno this week. It has CNC ported EZ heads, a Super Victor with Wilson porting and a 1250 Dominator. We were testing different race fuels. The Q16 made the most power with just a hair over 900 hp. I'll post a couple of pictures and a link to a video.

View attachment 1715002697

View attachment 1715002698

famous bob

mopar misfit

Big thanks to Rich from Fast Man EFI. He flew into town and helped me get the tune up correct. Here is a video of the startup:

surly not a stock 440 block !

I am the opposite of depressed. I am elated. I think it is just GREAT and I don't care if you are doing it just to advertise AREngineering. You don't have to give us any more information on the build. It gives us all hope. Keep it up!

EchoSixMike

Well-Known Member

Awesome. I'm doing something similar with B1 heads, although I was going to try a dual sync distributor, not a crank trigger. Dry sump, so no oil pump, so I am hoping timing won't be so "meh."

What sensor are you pulling of the standard distributor shaft area? I can't hear the commentary. S/F....Ken M

What sensor are you pulling of the standard distributor shaft area? I can't hear the commentary. S/F....Ken M

Awesome. I'm doing something similar with B1 heads, although I was going to try a dual sync distributor, not a crank trigger. Dry sump, so no oil pump, so I am hoping timing won't be so "meh."

What sensor are you pulling of the standard distributor shaft area? I can't hear the commentary. S/F....Ken M

I have a Holley dual sync distributor but decided not to use it. If you want to buy an unused dual sync shoot me a note since I don't have any plans for it. I ended up making my own cam sensor. I'll attach a couple of pictures of the cam sensor that I made.

I am the opposite of depressed. I am elated. I think it is just GREAT and I don't care if you are doing it just to advertise AREngineering. You don't have to give us any more information on the build. It gives us all hope. Keep it up!

Here is a video of the console during a couple of pulls. Camera work is a little poor as I pan between screens. I need to move the two screens closer together next time.

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,801

- Reaction score

- 3,578

Curious why you started the pull at 5k?

Old Man Mopar

Righteous Dude

Very impressive Andy!

So is this a 400 Low Deck based 512 with Trick Flow PP 240 or 270 heads?

So is this a 400 Low Deck based 512 with Trick Flow PP 240 or 270 heads?

Very impressive Andy!

So is this a 400 Low Deck based 512 with Trick Flow PP 240 or 270 heads?

No, this is an RB block with Indy EZ heads. It is 514 inches not 512.

Curious why you started the pull at 5k?

Because I don't really care about anything below 5000 rpm on this engine. Torque peak is higher than 5000 rpm so no reason to go below 5000.

Any specs on this beast?

There are specs in the article on the Hot Rod website: How to Modify Your Carburetor to Run Oxygenated Race Gas - Hot Rod Network

Old Man Mopar

Righteous Dude

Thanks. Sorry - I asked about Trick Flow because at a glance I thought that was a new Trick Flow intake but after blowing the picture up I see it is an Edelbrock.No, this is an RB block with Indy EZ heads. It is 514 inches not 512.

It is an Edelbrock Super Victor that has been heavily modified by Wilson Manifolds. That intake really works!Thanks. Sorry - I asked about Trick Flow because at a glance I thought that was a new Trick Flow intake but after blowing the picture up I see it is an Edelbrock.

Old Man Mopar

Righteous Dude

That intake looks much modified. Take a hint Edelbrock.

jbc426

Well-Known Member

Big thanks to Rich from Fast Man EFI. He flew into town and helped me get the tune up correct. Here is a video of the startup:

This is awesome, and a huge step in the direction of the future. Nice to see our top minds AndyF, Rich from FAST and Wilson manifolds collaborating to help big block Mopars take advantage and showcase the brilliant work that the entire Holley EFI team has created to retrofit our old carb'd motors to sequential EFI.

That cam sensor is brilliant and super clean. I'd like to see the crank trigger & cam sensor package that Andy sold by Holley, for a tidy fee to AndyF of course.

I haven't decided yet. They are fairly expensive to make in low qty so I need to see if there is a way to reduce the cost. Holley sells a Mopar dual sync distributor for $450 but it doesn't fit most aftermarket cylinder heads without a lot of grinding. So there is a need for a different solution. Here is a picture of the cam sensor I used as well as the crank trigger.Andy - very nice, are you going to make and sell the cam sensors for B and RB's? I would be interested in one for a B motor.

CP

I looked thru my parts and I do have a spare low deck cam sensor housing if you are interested. You would need to buy the sensor which is a Standard Motor Products LTX260T. You will also need some sort of pigtail harness which you can either grab off of a Ford Explorer in a wrecking yard or you can buy the Motocraft WPT196 pigtail. The housing with the shutter wheel is $200 plus shipping. If you are interested just shoot me a PM and we can work out the details.Andy - very nice, are you going to make and sell the cam sensors for B and RB's? I would be interested in one for a B motor.

CP

This cam sensor produces a 1 pulse per cam rotation. It uses a 180 degree shutter so the voltage is high for 180 degrees then low for 180 degrees. This setup works perfectly with the Holley system and Rich says it works with other EFI systems also but I've only tested it with the Holley. Here is a picture of the shutter inside of the housing. The LTX260T sensor sits on top of the housing and it senses the shutter wheel with a Hall effect sensor.

-