73ScampSS

Active Member

Hi everyone I am new to the forum here. I am having some issues with my transmission on a fresh rebuild.

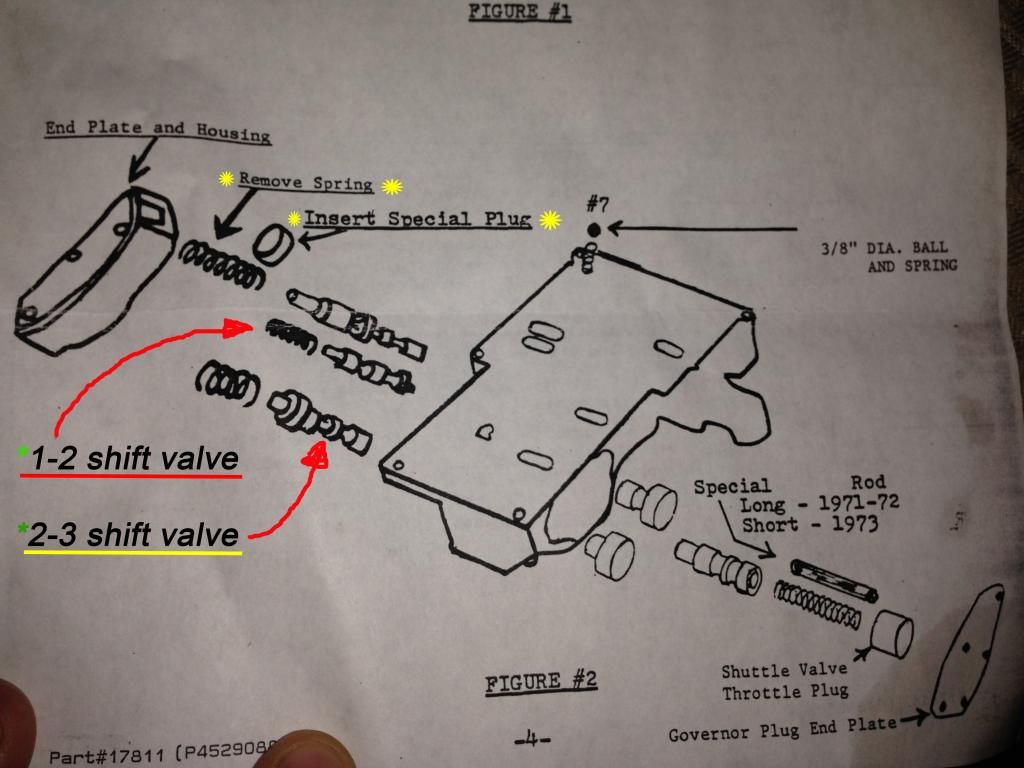

It is a 1973 904, and I added a Turbo Action Cheetah Power shift kit, and it will not shift into 3rd gear.

I have had the rpms up to 5000 and speedo says 70 mph, which I know is not accurate since I added 3.55 gears. It goes into reverse, and shifts 1-2 solid and is great in 2nd, but will not hit 3rd.

I am wondering if this is a problem with the valve body since the internals seem to be working fine, or possible governor pressure problem.

Has anyone else had a problem like this? Thanks in advance for any help..

It is a 1973 904, and I added a Turbo Action Cheetah Power shift kit, and it will not shift into 3rd gear.

I have had the rpms up to 5000 and speedo says 70 mph, which I know is not accurate since I added 3.55 gears. It goes into reverse, and shifts 1-2 solid and is great in 2nd, but will not hit 3rd.

I am wondering if this is a problem with the valve body since the internals seem to be working fine, or possible governor pressure problem.

Has anyone else had a problem like this? Thanks in advance for any help..