daniel9843

Active Member

Hi all,

Just wondering if somebody could help with my ballast resistor bypass on how to wire it correctly?.

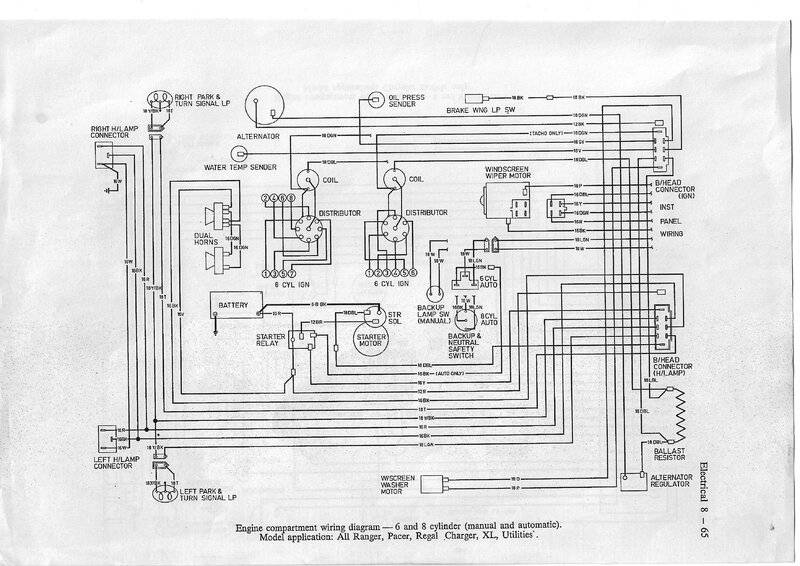

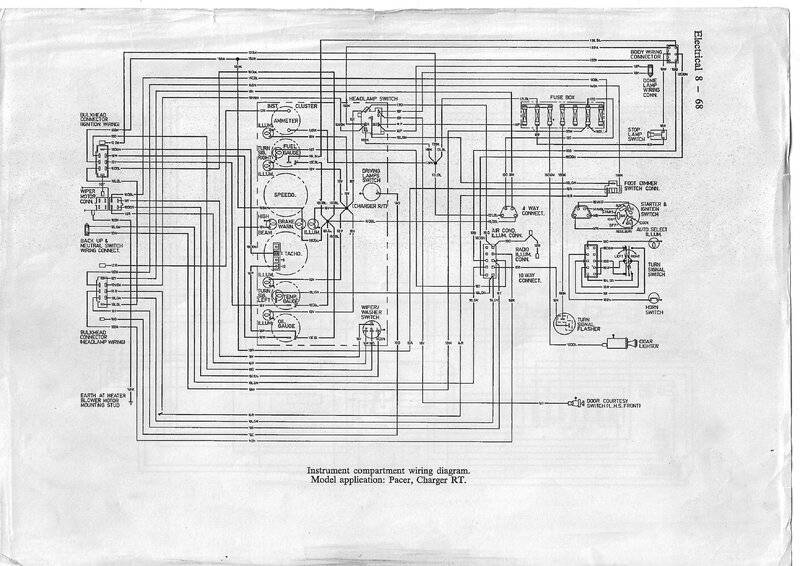

I live in Australia, this is a Chrysler Valiant VH series 1972 wiring diagram supplied.

I have a 1 wire altenator in the system now and a crane H I 6 ignition system.

I have bypassed the resistor with 1 wire across where the resistor originally ran,

just wondering if I have done it right ?. As I feel it has never ran quite right at idle.

Cheers Daniel

Just wondering if somebody could help with my ballast resistor bypass on how to wire it correctly?.

I live in Australia, this is a Chrysler Valiant VH series 1972 wiring diagram supplied.

I have a 1 wire altenator in the system now and a crane H I 6 ignition system.

I have bypassed the resistor with 1 wire across where the resistor originally ran,

just wondering if I have done it right ?. As I feel it has never ran quite right at idle.

Cheers Daniel