I have watched a lot of his videos. He does mostly Chevy stuff but he has a lot of good content.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cam gone flat? Here's a interesting video.

- Thread starter toolmanmike

- Start date

-

Interesting video although I don't think he came to any conclusions about the issue other than to just use roller cams because he doesn't know what the actual issue is. I would love for a cam manufacturer to explain what exactly goes on during the break in phase. The way I see it if either the cam lobe slope/angle or lifter crown are not matching the band of contact will be too narrow and cause partial film lubrication and rapid failure. Often people mix and matches cams and lifters so no wonder there are issues not that buying them from the same manufacturers would be any sort of a guarantee these days as there are supposedly only a few lifter manufacturers left. I read an article last week saying each auto manufacturer used to have its own lifter crown spec. As he mentions these specs and input from the auto manufacturers has probably long ago disappeared. Buying a cam and lifters that match may well be a crap shoot these days.

I'm in the middle of a budget build and got my hydraulic cam and lifters from Oregon Cams. They say they haven't had issues with the lifters they supplied (cheapies I think). I checked for lifter rotation and it looks good. I'll run proper break in oil and cross my fingers. I really didn't want to spend another $2k for a roller cam (lifters, cam, springs, pushrods, rocker arms) on a stock 340.

I'm in the middle of a budget build and got my hydraulic cam and lifters from Oregon Cams. They say they haven't had issues with the lifters they supplied (cheapies I think). I checked for lifter rotation and it looks good. I'll run proper break in oil and cross my fingers. I really didn't want to spend another $2k for a roller cam (lifters, cam, springs, pushrods, rocker arms) on a stock 340.

What he said although he didn't say it was the actual cause of the failure.Interesting video although I don't think he came to any conclusions about the issue other than to just use roller cams because he doesn't know what the actual issue is. I would love for a cam manufacturer to explain what exactly goes on during the break in phase. The way I see it if either the cam lobe slope/angle or lifter crown are not matching the band of contact will be too narrow and cause partial film lubrication and rapid failure.

True that. Not a good idea to mis match cam and lifters if you need warranty later.Often people mix and matches cams and lifters so no wonder there are issues not that buying them from the same manufacturers would be any sort of a guarantee these days as there are supposedly only a few lifter manufacturers left. I read an article last week saying each auto manufacturer used to have its own lifter crown spec. As he mentions these specs and input from the auto manufacturers has probably long ago disappeared. Buying a cam and lifters that match may well be a crap shoot these days.

I'm with you there. A roller set up is not cheap. I have been lucky not to have a failure but I haven't swapped many cans either.I'm in the middle of a budget build and got my hydraulic cam and lifters from Oregon Cams. They say they haven't had issues with the lifters they supplied (cheapies I think). I checked for lifter rotation and it looks good. I'll run proper break in oil and cross my fingers. I really didn't want to spend another $2k for a roller cam (lifters, cam, springs, pushrods, rocker arms) on a stock 340.

Thanks. I’m not a motor master, but I learned a few new things there.

He is probably on track with his guess as to the reasons for failure though. The reality is that the flat tappet is becoming ancient so the market is not there. If I owned a manufacturing company, I would concentrate on upcoming products, not outgoing.

He is probably on track with his guess as to the reasons for failure though. The reality is that the flat tappet is becoming ancient so the market is not there. If I owned a manufacturing company, I would concentrate on upcoming products, not outgoing.

Last edited:

Dartnut

Don't hate me because i'm beautiful

Good video.

I Thought he explained things quite well and used his experiences to back up his views.

Using the right oil from day one is the key to cam and lifter life on flat tappet cam and lifter combos.

Or buck up to a roller cam and lifters and eliminate most of the headaches...

I Thought he explained things quite well and used his experiences to back up his views.

Using the right oil from day one is the key to cam and lifter life on flat tappet cam and lifter combos.

Or buck up to a roller cam and lifters and eliminate most of the headaches...

plumkrazee70

Well-Known Member

Where it hit home with me isn't the hardness of the cam or lifters that is the issue. There was two things.

1. Using PROPER break in oil and PROCEDURE

2. The cam/lifter QC isn't what it used to be because it doesn't have to be (no need to supply oe) he mentioned the taper of the cam lobe and the flatness of the lifters.

1. Using PROPER break in oil and PROCEDURE

2. The cam/lifter QC isn't what it used to be because it doesn't have to be (no need to supply oe) he mentioned the taper of the cam lobe and the flatness of the lifters.

The number one thing besides breakin lube and the right oil is rpm. Upon initial start up, directly to 2500 rpm for 20-30 minutes for cam and lifter break in. Of course you need to have quality parts in your valve train.

my68barracuda

Well-Known Member

When installing new flat lifters / cam, one should always check that the basic machining characteristic that causes the lifter to spin as the engine is running is present.

1) place the cam side of the lifter against a very flat surface like a piece of window pane glass. Viewing from the side of the lifter down at the cam interface, the convex profile of the lifter should be apparent. The very center of the lifter should be pointed out with a very slight fall away to the outside diameter.

2) Place a straight edge across the cam lobs where the lifters contacts it. You will need to position the straight edge, so it is level and contacting two or more lobes at a time. Peering under the straight edge and maybe using a flash light you should be able to see the taper that is machined into the cam lob. With one side of each lob being higher than the other side of the same lob.

and lastly, I often wonder how many flat cam lobes that are wiped during break in are due to poor assembly practices, like verifying that the tappets spin with very light hand pressure at install. Lifter bore to lifter body clearance is pretty small. It would not take much soap scum or debris left in a lifter bore after a hot tank, or a slight nick on a lifter body due to carless handling to lock up a lifter and wipe a cam. The best oil and the best break in procedure will not overcome poor assembly practices.

1) place the cam side of the lifter against a very flat surface like a piece of window pane glass. Viewing from the side of the lifter down at the cam interface, the convex profile of the lifter should be apparent. The very center of the lifter should be pointed out with a very slight fall away to the outside diameter.

2) Place a straight edge across the cam lobs where the lifters contacts it. You will need to position the straight edge, so it is level and contacting two or more lobes at a time. Peering under the straight edge and maybe using a flash light you should be able to see the taper that is machined into the cam lob. With one side of each lob being higher than the other side of the same lob.

and lastly, I often wonder how many flat cam lobes that are wiped during break in are due to poor assembly practices, like verifying that the tappets spin with very light hand pressure at install. Lifter bore to lifter body clearance is pretty small. It would not take much soap scum or debris left in a lifter bore after a hot tank, or a slight nick on a lifter body due to carless handling to lock up a lifter and wipe a cam. The best oil and the best break in procedure will not overcome poor assembly practices.

Two things:

- I have never lost a flat tappet cam

- I am slowly getting everything on roller cam before my streak of good luck comes to an end

It’s been a while since I’ve reviewed it for any updates, but this is a good read form our friends at the crankshaft coalition that covers a lot of potential issues encountered during the break in process, as well as describes the forces at play. There are some hydraulic cam companies and certain new old stock grinds that I still trust. But, for the most part, I find myself drifting towards the stock type roller cam club, too.

Camshaft install tips and tricks

Camshaft install tips and tricks

Last edited:

The number one thing besides breakin lube and the right oil is rpm. Upon initial start up, directly to 2500 rpm for 20-30 minutes for cam and lifter break in. Of course you need to have quality parts in your valve train.

Yeah do all the right things like proper break in oil, cam lube, get it started right away (make sure everything is right with fuel, cooling and ignition and you have a timing gun ready to go), hold above 2000 rpm for 20 minutes and that is all you can do. Of course light springs for break in will help if you have heavy springs in it.

And check the lifter bottoms for convex and measure the cam lobes for taper.Yeah do all the right things like proper break in oil, cam lube, get it started right away (make sure everything is right with fuel, cooling and ignition and you have a timing gun ready to go), hold above 2000 rpm for 20 minutes and that is all you can do. Of course light springs for break in will help if you have heavy springs in it.

Problem is you can’t measure how much very easily. Hopefully the lifter isn’t dead flatAnd check the lifter bottoms for convex and measure the cam lobes for taper.

my68barracuda

Well-Known Member

sure you can, see post #8.

its either there or its not,

its either there or its not,

My point was knowing if the crown was correct or not. Sure you should be able to tell if its flat which would be a total fail. You can make sure they all rotate in the bores (tested mine yesterday) but it doesn't mean everything is totally right. It probably just means that they won't burn the edges off of the cam lobe.sure you can, see post #8.

its either there or its not,

How To Check Flat-Tappet Lifter Crown, Lobe Taper, And Lifter BoresMy point was knowing if the crown was correct or not. Sure you should be able to tell if its flat which would be a total fail. You can make sure they all rotate in the bores (tested mine yesterday) but it doesn't mean everything is totally right. It probably just means that they won't burn the edges off of the cam lobe.

my68barracuda

Well-Known Member

That is a great article,

If I need to do all those checks I'm going roller

The actual radius on the lifter is not as important as some think...as long as it has a radius [ high point in the centre ]. What it will affect is the speed of rotation of the lifter & long term, possibly how many miles it will do. Doesn't cause a failure during break in.

The original 6 pack cam had the same timing specs as the Magnum cam. The 6 pack lifters were low taper & had a separate part # [ & were used because the 6 pack used stronger v/springs ]. This allowed more contact area at the lobe/lifter interface.

The original 6 pack cam had the same timing specs as the Magnum cam. The 6 pack lifters were low taper & had a separate part # [ & were used because the 6 pack used stronger v/springs ]. This allowed more contact area at the lobe/lifter interface.

Right at the 20 minute mark, he hit on what may have caused the failure of the MP '528 in my car.

High detergent oil with zddp is pointless.....

I learned that the hard way. From early on, I used VR-1 with the Comp Cams supplement at every oil change.

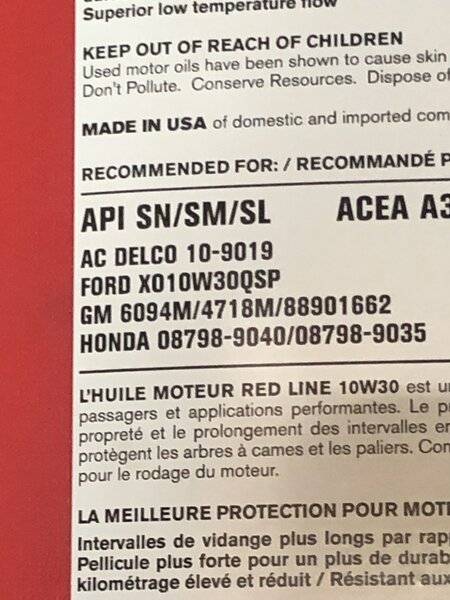

Then in early 2021, I had the oil pan off to pound out a dent. I switched to the Redline synthetic with this rating:

SN SM SL are the highest detergent ratings available. Yeah, the label claimed the oil had ZDDP but so what? This was pointless. The ZDDP splashes on the parts and the detergent prevents it from sticking.

Secondly:

The reason for the 2000 rpm break in is because the camshaft and lifters rely on splash oiling. The cam gets no direct oiling. The oil squirts out the rods and mains and flings onto the underside of the cam and lifters. Below 2000 rpms, there isn't adequate movement of oil to reach the cam.

High detergent oil with zddp is pointless.....

I learned that the hard way. From early on, I used VR-1 with the Comp Cams supplement at every oil change.

Then in early 2021, I had the oil pan off to pound out a dent. I switched to the Redline synthetic with this rating:

SN SM SL are the highest detergent ratings available. Yeah, the label claimed the oil had ZDDP but so what? This was pointless. The ZDDP splashes on the parts and the detergent prevents it from sticking.

Secondly:

The reason for the 2000 rpm break in is because the camshaft and lifters rely on splash oiling. The cam gets no direct oiling. The oil squirts out the rods and mains and flings onto the underside of the cam and lifters. Below 2000 rpms, there isn't adequate movement of oil to reach the cam.

The other recommendation I saw was to run 10W30 oil and not anything heavier although this may be more for proper lifter operation. It was in the Lifter section. Their articles don't mention this:

While on the subject, I think it’s worth mentioning that the big GMC industrial truck V6 gasoline engines had a well or wells in the valley between the cam and crank that stayed full of engine oil. I don’t know if there was a constant pressure supply to this area or if it was just oil that came from the top end on its return path, but the overflow point was above the lifters. All in a relatively low rpm heavy duty engine built in the pre-EPA Detroit Iron Age. It makes me think that running a spray bar through the valley with a hole drilled above each cam lobe plumbed to an oil gallery wouldn’t be a bad thing to have if it could be done without causing oil supply issues elsewhere. My machinist says that some of his most frequent customers have flat tappet cam hot rods they like to take through parades or rod runs. Too much idle time without enough splash.

pishta

I know I'm right....

My 82 Mazda has a spray bar over the cam and it's an OHC so I'm sure it's needed as there is no crank sling on an OHC. I've never wiped a lobe ( knock on wood) but I don't deal with battleship springs or wild lifts either. Spray bar would be easy to fab up. Just a small closed end brass pipe with some strategically drilled .010 holes on the underside plumbed to an oil feed. Mount on bottom of a Moroso lifter valley pan, bottom of intake or rigid directly across the valley above the camshafts. R blocks need not apply as they have a restricted camshaft exposure valley. 340 shown with all it's camshafts oiling access.

pishta

I know I'm right....

Could also go with EDM lifters...direct oil pressurized onto cam lobes at lifter base. Maybe grooving the lifter bores so lifter galley oil bleeds out onto camshaft. More than one way to skin the cat.

-