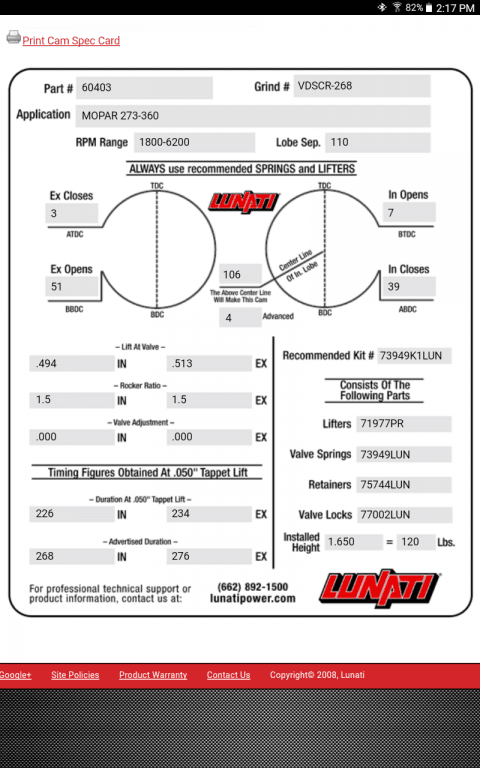

Trying to degree the cam in a 360 I've been building for the last year or so, it's a Lunati 60403 that I bought used. ProGear 9 keyway timing chain, on the crank at 0. Grabbed a stock timing chain set off the shelf, keyways line up the same. Double and triple checked myTDC with a piston stop. Lunati's instructions are to check at .050" lift, and the cam card says 7 degrees BTDC. I keep ending up at 1-2 degrees ATDC. Rolled it around to the intake closing side, and at .050" off the base circle got 47 degrees ABDC, when it's supposed to be 39. Can this thing actually be ground 8+ degrees retarded? That seems absolutely nuts to me. I'm hoping that (once again) I'm just having a simple brain freeze.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can't be the cam, it has to be me?

- Thread starter fshd4it

- Start date

-

yellow rose

Overnight Sensation

Degree the cam to 106 Intake Center Line and don't worry if the @ .050 numbers ain't perfect. The lifter bank angles and lifter bore axes are pro all off a bit, making the @ .050 numbers off a little.

Verify TDC. Set the dial indicator on the lifter and find max lift. With the lobe at max lift, rotate the crank to 106 degrees ATDC. Put the gears and chain on and VERIFY ICL and correct as you may not be exactly at the center of the lobe.

Verify TDC. Set the dial indicator on the lifter and find max lift. With the lobe at max lift, rotate the crank to 106 degrees ATDC. Put the gears and chain on and VERIFY ICL and correct as you may not be exactly at the center of the lobe.

I had same cam and similar issue... There was something funky about the directions or card... can't remember now.

I about wore out the engine spinning that motor with a breaker bar ! I even went and bought a new dial indicator thinking it was the issue.

I about wore out the engine spinning that motor with a breaker bar ! I even went and bought a new dial indicator thinking it was the issue.

Thanks YR, I'll go out and give that a shot.Degree the cam to 106 Intake Center Line and don't worry if the @ .050 numbers ain't perfect. The lifter bank angles and lifter bore axes are pro all off a bit, making the @ .050 numbers off a little.

Verify TDC. Set the dial indicator on the lifter and find max lift. With the lobe at max lift, rotate the crank to 106 degrees ATDC. Put the gears and chain on and VERIFY ICL and correct as you may not be exactly at the center of the lobe.

A long time ago there was a member found the same offset or deviation. Someone replied that 7 degrees retarded is carved in stone by the mechanical engineering aspects. The explanation ( simple or complicated ) I don't recall. According to him 100% OEM parts would check the same.

yellow rose

Overnight Sensation

Are you using a solid lifter or a hydraulic?

Evildart

Dart Member

Are you using offset keys?

I know I had to use them on mine.

I got it with in 2 degrees of what it was suppose to be.

I know I had to use them on mine.

I got it with in 2 degrees of what it was suppose to be.

Before I did as Yellow Rose posted, I checked the ICL with the cam as it was (degrees @ .020 before and after max lobe lift, difference divided by 2, I was assuming the nose is the same radius on both sides). Got 113.5 degrees ATDC. Followed his directions, ended up with the chain fitting at the 8 degree keyway. ICL is now at 106, but I'll put my piston stop plate back on and verify TDC one more time. Am I still correct in thinking this cam is 8 degrees off?

SolidAre you using a solid lifter or a hydraulic?

yellow rose

Overnight Sensation

Before I did as Yellow Rose posted, I checked the ICL with the cam as it was (degrees @ .020 before and after max lobe lift, difference divided by 2, I was assuming the nose is the same radius on both sides). Got 113.5 degrees ATDC. Followed his directions, ended up with the chain fitting at the 8 degree keyway. ICL is now at 106, but I'll put my piston stop plate back on and verify TDC one more time. Am I still correct in thinking this cam is 8 degrees off?

It is off with all the tolerance stack up, but all it will know is where you have it installed. It won't know anything else. If you have the ICL at 106 that will be golden.

This is the very best example of why you have to degree every cam. Every time. You can have this much stack up between the cam, crank and gear key ways.

Here's the crank sprocket. Well, since I bought 2, it's actually a picture of the other one. But I did compare them, and they match. The other fun part is that only half of the keyways (of either one) allow the sprocket to slide onto the crank. I ended up using the 8 degree retarded keyway when putting the chain back on. as it was the one that lined up best. It should have been th 8 advanced, correct?There is the possibility that the crank sprocket is marked incorrectly.

Ted

nm9stheham

Well-Known Member

Sure can be that far off.

We can't check your technique without knowing a few things. These are probably dumb question and not meant to insult you.

- Using a degree wheel? Yes? Degrees CW from the 0 on the degree wheel are BTDC, and CCW from the 0 are ATDC.

- Are you measuring at .050" TAPPET lift? Not at .050" valve lift right? (But that would not show up both intake events off in the same direction....)

- If you needed to advance the cam, then yes, use the 8* advance marked slot. Your last question is perplexing....

We can't check your technique without knowing a few things. These are probably dumb question and not meant to insult you.

- Using a degree wheel? Yes? Degrees CW from the 0 on the degree wheel are BTDC, and CCW from the 0 are ATDC.

- Are you measuring at .050" TAPPET lift? Not at .050" valve lift right? (But that would not show up both intake events off in the same direction....)

- If you needed to advance the cam, then yes, use the 8* advance marked slot. Your last question is perplexing....

Subscribed

No offence taken. Using a degree wheel, same one I've had for 20+ years, just not used all that much. Heads aren't on the motor, and the dial indicator plunger is directly into the lifter. As I mentioned before, 4 or 5 of the 9 keways on the crank sprocket won't go over the crank key, or bind up for some other reason...so after setting everything up as Yellow Rose posted, I just played with combinations (ignoring the dots on the sprocket) until I found one that lined up correctly. I'm thinking it was coincidence that it happened to be the 8 degree retarded slot.Sure can be that far off.

We can't check your technique without knowing a few things. These are probably dumb question and not meant to insult you.

- Using a degree wheel? Yes? Degrees CW from the 0 on the degree wheel are BTDC, and CCW from the 0 are ATDC.

- Are you measuring at .050" TAPPET lift? Not at .050" valve lift right? (But that would not show up both intake events off in the same direction....)

- If you needed to advance the cam, then yes, use the 8* advance marked slot. Your last question is perplexing....

yellow rose

Overnight Sensation

No offence taken. Using a degree wheel, same one I've had for 20+ years, just not used all that much. Heads aren't on the motor, and the dial indicator plunger is directly into the lifter. As I mentioned before, 4 or 5 of the 9 keways on the crank sprocket won't go over the crank key, or bind up for some other reason...so after setting everything up as Yellow Rose posted, I just played with combinations (ignoring the dots on the sprocket) until I found one that lined up correctly. I'm thinking it was coincidence that it happened to be the 8 degree retarded slot.

The eight degree slot makes sense. If in the straight up position if you get basically a 114 ICL (or as you said 113.5) and you now have it at 106, you advanced the cam 8 degrees to actually get installed straight up.

I hope that makes sense.

MOPAROFFICIAL

Oogliboogli

A lot of cams end up advanced dot to dot and so its pretty common to end up regarding it. Mp cams are the poster child for this.Here's the crank sprocket. Well, since I bought 2, it's actually a picture of the other one. But I did compare them, and they match. The other fun part is that only half of the keyways (of either one) allow the sprocket to slide onto the crank. I ended up using the 8 degree retarded keyway when putting the chain back on. as it was the one that lined up best. It should have been th 8 advanced, correct?

nm9stheham

Well-Known Member

Without any of us begin there, it sure SOUNDS like you got it right. One way to check that you advanced it: Assuming you still have the dot on the cam sprocket at 6 o'clock with #1 at TDC, then that dot now ought to be about 1/2 a tooth to the left of where it was before.

BTW, some keyways on some parts are tight, but being OK on some and not OK on others on the same part may say that the machining is poor, like having multiple bits on a machine that are not all the same size.

BTW, some keyways on some parts are tight, but being OK on some and not OK on others on the same part may say that the machining is poor, like having multiple bits on a machine that are not all the same size.

-