Backstory is that I’m building a 5.9 magnum engine and wanted to A) use a serpentine belt and B) use billet pulley from March Performance.

I got my pulleys a while back but it turns out that March doesn’t make a cap or nose cone piece to dress out the water pump if you are going with an electric fan. So I designed my own and sent the CAD file off to be CNC machined from aluminum. It arrives tomorrow!

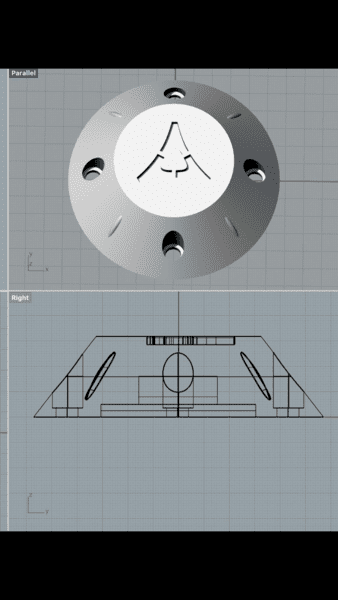

Below is a pic of the water pump with no cap, and the one I designed. I’ll post a pic of the part when it arrives (assuming I made it right and it was machined right!)

If there’s a few others interested in this part let me know and I’ll see what the price will be to do a small batch.

I got my pulleys a while back but it turns out that March doesn’t make a cap or nose cone piece to dress out the water pump if you are going with an electric fan. So I designed my own and sent the CAD file off to be CNC machined from aluminum. It arrives tomorrow!

Below is a pic of the water pump with no cap, and the one I designed. I’ll post a pic of the part when it arrives (assuming I made it right and it was machined right!)

If there’s a few others interested in this part let me know and I’ll see what the price will be to do a small batch.