THANKS HERB

had guy at Chrysler look for that, he never found it.

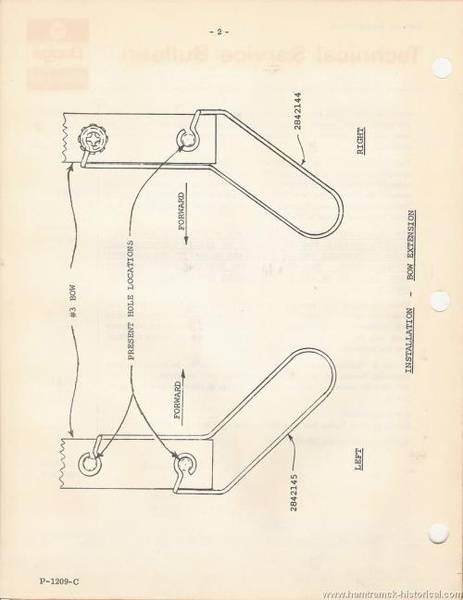

I made the ones on my car and had one original to use for a pattern. Gave that one back to the owner plus a set I made for him. Doug Carpenter got the other good set I had and what I have now isn't good to use as pattern.

The wire is .063 piano wire (mic'ed original) I spent a lot of time bending to get them to fit right. When I tried to make some with request I just couldn't get motivated to do it. (Once I got one done was easy, getting that 1st one done took weeks) but this has been 8 years ago, so today like starting from scratch

I offered to send what I have left of the wire and the left and right I have that were early prototype. One guy said he would try it but that was a long time ago and haven't heard nothing since.

If someone has the desire to recreate these I will offer again the stuff for free. Will mail it to you. And maybe you can make some. Personally the material is minimal but labor is high to make by hand. A jig that could hold and bend would make reproducing much more simple. But I was making a set for my car and a spare for Jim (guy that let me use his original)

Don't know how many could be made with the wire I have left. Bought the wire at Fastenal.