Hey everyone I'm looking for some decent roller rockers in a 1.6 ratio not wanting junk but don't want to break the budget with jesels either. I was looking at the PRW rockers what are your thoughts and opinions on these?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Decent 1.6 ratio roller rockers?

- Thread starter V8-valiant

- Start date

-

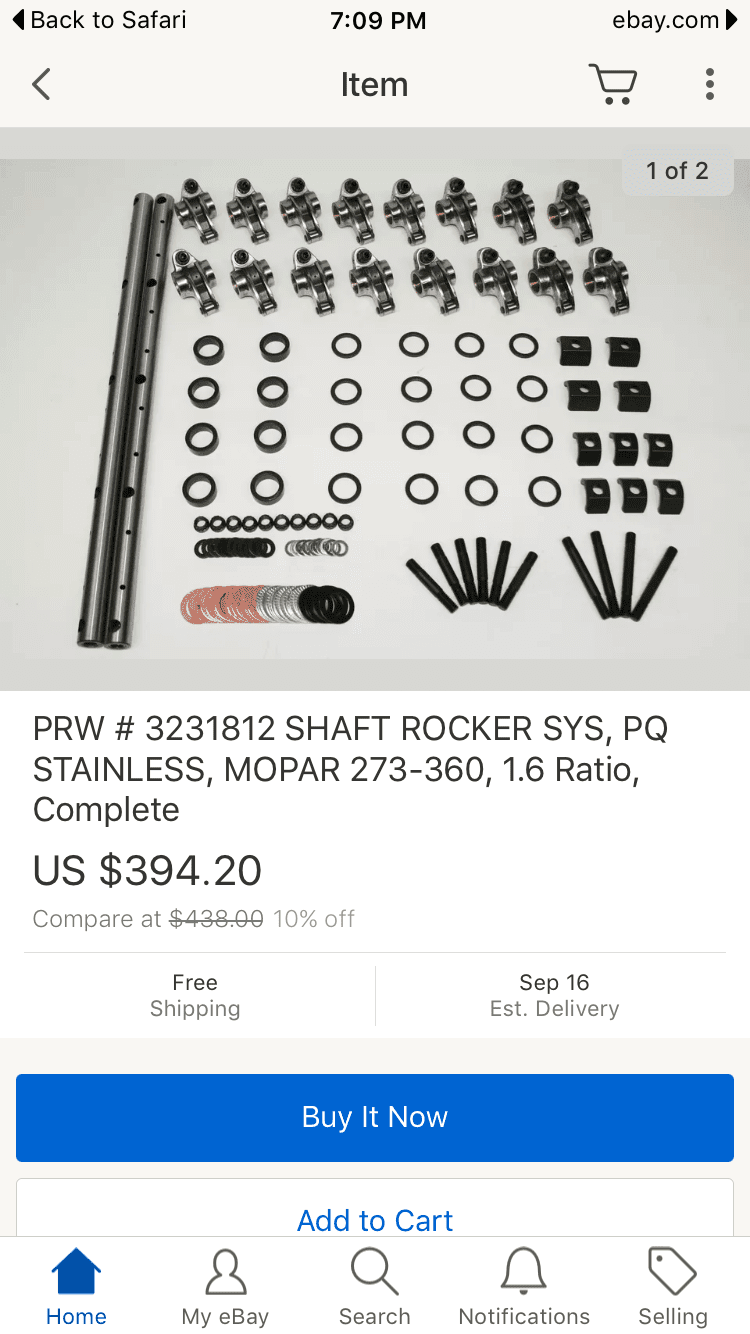

They look very similar to these:

Mopar Chrysler SB 318 340 360 160 Ratio Stainless Steel Roller Rocker Arm Set

Mopar Chrysler SB 318 340 360 160 Ratio Stainless Steel Roller Rocker Arm Set

The main thing is, though, why do you want the 1.6 ratio? The Factory and aftermarket standard is 1.5 and cams are ground to this.

Unless it would be a cheap upgrade to mimic a larger camshaft without actually installing one... there is always that reason.

- boingk

Unless it would be a cheap upgrade to mimic a larger camshaft without actually installing one... there is always that reason.

- boingk

the factory non adjustable rockers are no where 1.5......small block 59 degree rocker system also contributes for loss of gross lift...the 1.6 get it back and a little more...

Rockers/pushrods are one area you don't want to go the cheap route. I use and recommend Harland Sharpe. And on the subject of factory rockers, there have been a few articles on the factory ratio. They have found them to be anywhere from 1.35-1.50.

Inertia

Well-Known Member

I don't see where it says bearing, or bushing on the shaft, and I would never use a needle bearing/shaft again. I prefer a bushed shaft rocker for longevity.

jmo.

jmo.

mopowers

Well-Known Member

Those rockers have bushings. Inspect the hell out them. I had one in the set that I bought that was all buggered up. Other than that, I like them in my engine with a mild hydraulic flat tappet. What cam are you planning on using?

Mark with bullet cams that will be providing my cam suggested for what my build is gonna be to run a set of 1.6 rockers.The main thing is, though, why do you want the 1.6 ratio? The Factory and aftermarket standard is 1.5 and cams are ground to this.

Unless it would be a cheap upgrade to mimic a larger camshaft without actually installing one... there is always that reason.

- boingk

What is your intended use ? ...what cam...solid hydraulic roller or what?...spring pressure?

The cam is a custom grind from bullet cams. Solid roller for a turbo motor that will be going together this winter. Spring pressure if I remember is 300.

I agree the last set I ran were the aluminum 1.6 rockers from PRW and they had needle bearings in them. I didn't like the idea but ran them anyways. These have bushings.

Rockers/pushrods are one area you don't want to go the cheap route. I use and recommend Harland Sharpe. And on the subject of factory rockers, there have been a few articles on the factory ratio. They have found them to be anywhere from 1.35-1.50.

I agree I don't want to skimp but the Harland sharp rockers are a bit pricy and require longer valves. Would like to run my Indy RHS heads on this motor without having to change all the valves also....

"Harland Sharp SB Mopar kits require taller valves. Approximately .100-.150 are necessary for correct geometry but sometime lash caps can be used."

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,074

- Reaction score

- 4,065

The cam is a custom grind from bullet cams. Solid roller for a turbo motor that will be going together this winter. Spring pressure if I remember is 300.

If it's a solid roller I'll bet that 300# is on the seat.

Do they have a "ball" or a "cup" end on them. The one set we tried had 15 "ball" ends and 1 with no threads! I ask this because you then may need a custom set of pushrods. The "valve spring shims" used as spacers is a bit cheezy . They also had needle bearings. These PRW rockers and custom pushrods looks like a similar cost to a real set of rockers, perhaps a set of comp cams!

dadodgekid

When in doubt... floor it

Dont waste your time with those ebay rockers, espically building a turbo motor?!?! There is going to be more stress on the rocker body itself, let alone extra spring pressure of the solid roller. I vote hughes rockers, killer oiling to the tip of the valve, and its a super tough rocker. Even a used set of harlands or crane aluminum bodys, is better than the chinese rockers. Ive got a set of my 440 and i had to hone the bushings and, while i was at it polished the rocker shifts. Every bolt passage on the shafts was super sharp, like they never de-burred the shafts before polishing. the shaft finish was not the best either. Dont skimp on a turbo build IMO.

nm9stheham

Well-Known Member

I would suggest avoiding the eBay PRW's regardless any type. We bought a set of the aluminum PQ's with needle bearings (for about $224). The shafts were too soft and had bad grooves in them after 1000 miles, with just .500 lift and about 300# open pressure. The problem is that you may well be getting seconds for any and all of the parts, and the sellers doesn't check the parts out at all; they may just kit parts up from here and there to make a complete set and sell them off.

Ours actually came from PRW (per both the shipping address and the PayPal receipt), although the ebay seller was another name, and claimed they were obsolete production parts that PRW had sold off to them. That was not true, I found out later.

Ours actually came from PRW (per both the shipping address and the PayPal receipt), although the ebay seller was another name, and claimed they were obsolete production parts that PRW had sold off to them. That was not true, I found out later.

I have used the PRW stainless rockers on 600+ hp big blocks with hyd roller cams and over 400# open spring pressure. With proper oiling, set up, and installation protocols, they work very well. Pushrod side geometry is way better than Harland Sharp, or even Hughes. Comp doesn't offer anything other than 1.5 ratio. The PRW aluminum rockers are no different in design from a Harland Sharp rocker, so not so good there. Btw, using a longer valve, as recommended by Harland Sharp, will make the already terrible rocker geometry much, much worse. The shafts need to be relocated to fix geometry.I would suggest avoiding the eBay PRW's regardless any type. We bought a set of the aluminum PQ's with needle bearings (for about $224). The shafts were too soft and had bad grooves in them after 1000 miles, with just .500 lift and about 300# open pressure. The problem is that you may well be getting seconds for any and all of the parts, and the sellers doesn't check the parts out at all; they may just kit parts up from here and there to make a complete set and sell them off.

Ours actually came from PRW (per both the shipping address and the PayPal receipt), although the ebay seller was another name, and claimed they were obsolete production parts that PRW had sold off to them. That was not true, I found out later.

There is no other way.

nm9stheham

Well-Known Member

My concern is not with the rockers, B3RE... it is with the sourcing. eBay sourcing on something like this is a possible crapshoot IMHO on what parts you are actually getting..... new, seconds, mixed? We can't see who the OP is thinking of buying from.I have used the PRW stainless rockers on 600+ hp big blocks with hyd roller cams and over 400# open spring pressure. With proper oiling, set up, and installation protocols, they work very well.

Sorry, my reply wasn't supposed to be directed at you. I knew what you where referring to, because I've made that same point myself. I guess I'm too accustomed to the Moparts format where REPLY doesn't include a quote.My concern is not with the rockers, B3RE... it is with the sourcing. eBay sourcing on something like this is a possible crapshoot IMHO on what parts you are actually getting..... new, seconds, mixed? We can't see who the OP is thinking of buying from.

Yes, buying from a direct dealer, who will stand behind the product, is your best bet. The problem you mentioned with the soft shafts was addressed, and I know PRW directly stood behind them in the instances I am aware of. They have even sent me extra individual rockers, in case I need to warranty any. So far that has been 1, and failure was likely due installing dry.

cannucky

The Guy With No Birthday

I just recieved a hand picked set of those direct from PRW after wearing out the bearings and shafts on the last set . The story of the employee that was building sets from reject parts he was smuggling out the back door and selling on ebay is well known but I would only buy this sort of part from a reputable dealer such as B3RE who will be making my rocker relocation kit once the heads come home from being lapped.My last set did see 25k miles over 5years in a 410 inch stroker making over 520hp so even tho they eventually ate themselves I have no fears using them again.

-