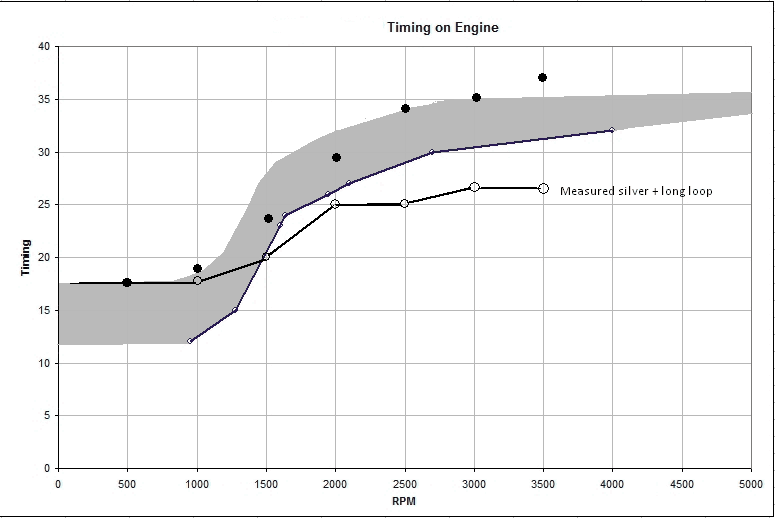

Not sure where to go at this point. The heavy long looped spring obviously did not do what I had expected. There are two springs remaining in the kit (gold and silver) that could replace the heavy long looped one. Neither would bring in timing at lower speeds, I think.View attachment 1715766129

He's getting there.

He learn more going step by step and seeing the changes he makes.

View attachment 1715766130

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Distributor curve help needed

- Thread starter Ricks70Duster340

- Start date

-

Mattax

Just the facts, ma'am

Lets see what you got.I found a heavy long looped spring in my stash, so replaced the black spring with that. Also replaced the gold spring with the lightest which is silver. That change produced:

500-18*

1000-18*

1500-20*

2000-25*

2500-25*

3000-27*

3500-27*

Still holding the weights back at 1000 rpm.

Might be better yet if you have a Chrysler light spring in your stash.

Softer spring rate will have thinner wire and/or more coils.

With the existing two springs, on the silver spring increase the loop or slightly bend in the sping perch.

It's the spring tension that is keeping the weight from moving outward with acceleration.

The tension is a combination of the distance the spring is stretched and the spring rate.

Reducing the tension on the primary spring will let the weights move out at lower rpm.

Advance curve will start earlier

Then to delay the heavy spring, bend the long loop perch slightly in.

Mattax

Just the facts, ma'am

Yea. That's why its good to do this stuff step by step.The heavy long looped spring obviously did not do what I had expected.

Its not as obvious as it first looks.

Since you changed the gold spring for the silver spring, anything was possible.

Sometimes the 'soft' spring has more tension so initially applies more force. The books and magazines never mention that.

Force = spring rate x distance stretched.

Last edited:

I left those two springs in there and bent the tabs in. I noticed that the two pegs that slide in and out of the crossmember are already 1/2 way in the slot. Strange?Yea. That's why its good to do this stuff step by step.

Its not as obvious as it first looks.

Since you changed the black spring for the silver spring, anything was possible.

Sometimes the 'soft' spring has more tension so initially applies more force. The books and magazines never mention that.

Force = spring rate x distance stretched.

Mattax

Just the facts, ma'am

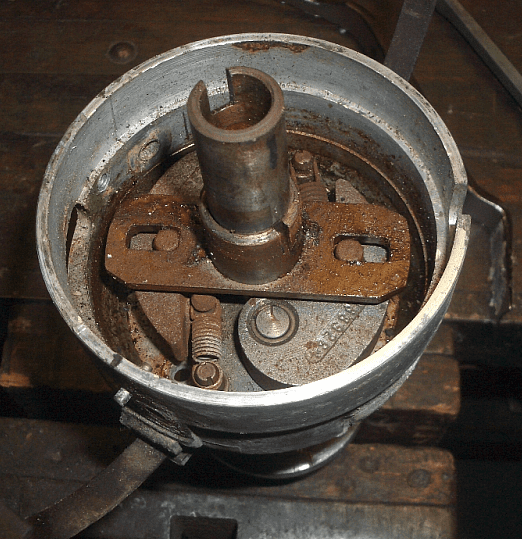

Halfway on the long loop would be about half of the advance available. 8.5* crankshaft degreesI left those two springs in there and bent the tabs in. I noticed that the two pegs that slide in and out of the crossmember are already 1/2 way in the slot. Strange?

View attachment 1715766142

The primary spring should have enough tension to hold the weight at the bottom of the slot.

Otherwise you will find the timing changing with idle rpm.

Last edited:

The heavy long loop spring was preventing the weight from fully retracting. I removed that spring and put in a silver one with the following results:Halfway on the long loop would be about half of the advance available. 8.5* crankshaft degrees

The primary spring should have enough tension to hold the weight at the bottom of the slot.

Otherwise you will find the timing changing with idle rpm.

View attachment 1715766154

View attachment 1715766155

500-18*

1000-19*

1500-23*

2000-29*

2500-34*

3000-35*

3500-37*

Mattax

Just the facts, ma'am

Well you got it in the ballpark now.

Hopefully you see what the different adjustments do now.

I'd like to see faster rise in the timing from 1200 to 1800 rpm. Especially if you find the engine likes a little less intial (tested in gear) you can set it with less intial and still have the off-idle WOT timing it probably wants. Same if you find the 37 at 3500 is too much at WOT.

Probably will need something closer to a factory set of springs like used in a 4bbl points car.

No idea how the long loop spring you have would block the weights but you can take some pics and/or contact halifaxhops.

Maybe Halifaxhops will have some springs that will work with the points distributor.

Next steps are up to you. If you want to continue refining the initial and mechanical, or make a trial with vacuum advance then come back to tuning the initial and mechanical. Depends on your focus and what your plans are. If your taking it to the drag strip or on family cruise thise weekend can shift the test plan big time!

If you do hook up the vac advance, the timing from 2500 - 3000 may contribute to pinging when cruising. Its borderline right there depending on the vac advance and the engine specifics. Yes the vac advance can be adjusted to some extent but no point in making major mods there if the mechanical advance still needs tweaking.

A little ping at cruise is tolerable. Any ping under heavy throttle is not.

Hopefully you see what the different adjustments do now.

I'd like to see faster rise in the timing from 1200 to 1800 rpm. Especially if you find the engine likes a little less intial (tested in gear) you can set it with less intial and still have the off-idle WOT timing it probably wants. Same if you find the 37 at 3500 is too much at WOT.

Probably will need something closer to a factory set of springs like used in a 4bbl points car.

No idea how the long loop spring you have would block the weights but you can take some pics and/or contact halifaxhops.

Maybe Halifaxhops will have some springs that will work with the points distributor.

Next steps are up to you. If you want to continue refining the initial and mechanical, or make a trial with vacuum advance then come back to tuning the initial and mechanical. Depends on your focus and what your plans are. If your taking it to the drag strip or on family cruise thise weekend can shift the test plan big time!

If you do hook up the vac advance, the timing from 2500 - 3000 may contribute to pinging when cruising. Its borderline right there depending on the vac advance and the engine specifics. Yes the vac advance can be adjusted to some extent but no point in making major mods there if the mechanical advance still needs tweaking.

A little ping at cruise is tolerable. Any ping under heavy throttle is not.

Mattax

Just the facts, ma'am

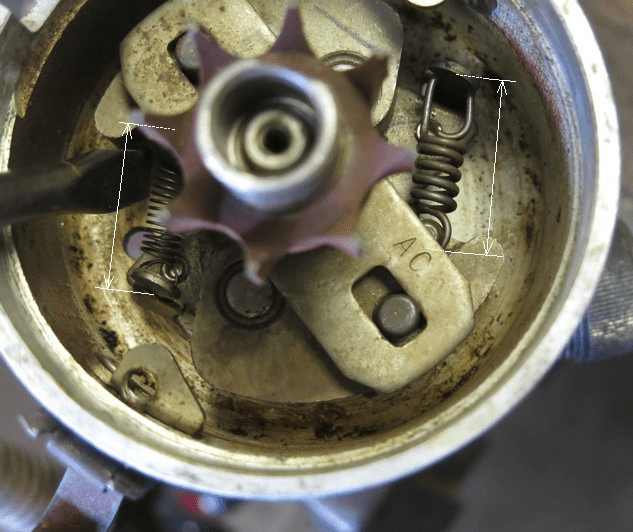

Sure looks like the weight is free to move in this photo.No idea how the long loop spring you have would block the weights but you can take some pics and/or contact halifaxhops

Really appreciate you working with me on this. I'll drive it tomorrow morning and see what we have. That garage was so hot this afternoon that it ran me out and into the shower!Sure looks like the weight is free to move in this photo. View attachment 1715766241

View attachment 1715766242

When I pulled the top off, the weight connected to the heavy spring was not fully retracted. The spring was on the pin but had a lot of slop in it so did not provide any tension. After this change I did see the idle drop from 750 to 650 in gear. Was a bigger drop before making these changes. Tomorrow's test will tell more. Thanks again!

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,636

- Reaction score

- 13,870

Are your Post #1numbers with the V-can defeated?I did put it back to 16* initial and it is most certainly a bow-wow. Very lazy at low speeds. Will put it up to 18 and try again.

Mattax

Just the facts, ma'am

Sounds good. Cool off!

I've got to get ready for two days playing in the sun and rain.

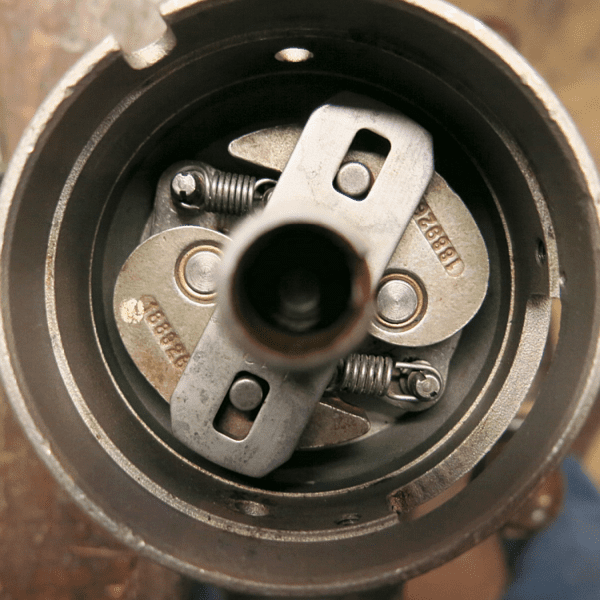

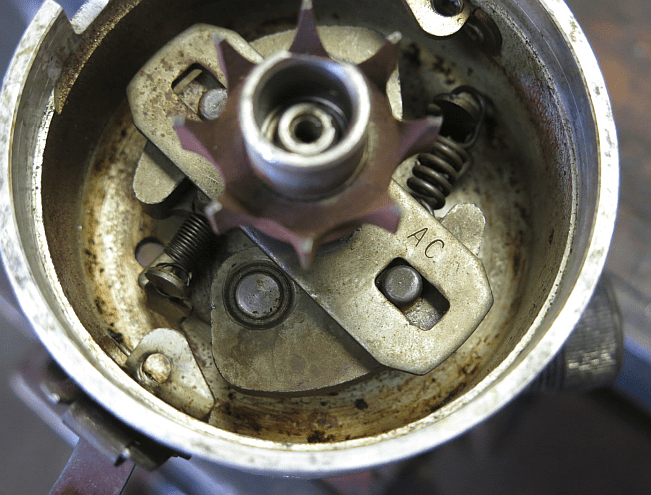

The primary spring needs to pull its weight against the inside of its slot.

The secondary weight will then follow. There may be a little slop between the slot and the second weight's pin. That's OK.

Here's an ugly example. You can see ther secondary weight has some play but the primary one is tight to the inside.

There needs to be enough side play between the slots and the pins so they run free. The machining on most of these are not that precise. It doesn't effect operation and sometimes even helps it.

A cleaner example (with a heavier primary spring installed).

Direct Connection race distributor (no vac advance) initial.

When the governor plate has rotated enough degrees, the secondary spring will engage its weight and slow the advance.

I've got to get ready for two days playing in the sun and rain.

ExactlyThe spring was on the pin but had a lot of slop in it so did not provide any tension

It will retract from the motion of the governor plate.the weight connected to the heavy spring was not fully retracted

The primary spring needs to pull its weight against the inside of its slot.

The secondary weight will then follow. There may be a little slop between the slot and the second weight's pin. That's OK.

Here's an ugly example. You can see ther secondary weight has some play but the primary one is tight to the inside.

There needs to be enough side play between the slots and the pins so they run free. The machining on most of these are not that precise. It doesn't effect operation and sometimes even helps it.

A cleaner example (with a heavier primary spring installed).

Direct Connection race distributor (no vac advance) initial.

When the governor plate has rotated enough degrees, the secondary spring will engage its weight and slow the advance.

Yes, the can was unplugged.Are your Post #1numbers with the V-can defeated?

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,636

- Reaction score

- 13,870

Well then yes, I would limit the cam to 20* and reset the power-timing to in the range of; 34* at 3200 to 36* at 3600, and just drive it. This should make the Idle-timing to be 20 degrees less, which should be lots.

If you need more power below stall, the right thing to do is increase the cylinder pressure.

If you need more power at low speed then you need a higher stall.

If the power sucks all the time in first gear, you need a bigger number rear gear. Or a bigger engine.

If you just need a lil more power at Part Throttle and low speed, get more timing from the Vcan.

My stocker made 22*. @TrailBeast got 24* out of his. Just map out at what throttle opening yours starts dropping off, and run in the zone, for max torque. I installed a vacuum gauge on the signal line, to tell me where I was on the throttle. Easy-Peasy.

BTW

I run that one-long loop 318 spring and it is what helps my combo run 87E10 at 11/1 Scr; by delaying my "all-in" to ~3400rpm.

The little one gets me 28*@2800 starting from 14* initial at about 900/1000rpm. Great curve for my combo. Yes it had more torque with more low-rpm timing, but if smokes the tires just the same with less timing,lol.

My V-can brings 22* to the table any time the throttle is reduced. By 1600 or so, at PT, the timing is getting to be over 40, and by 2000, it could be as high as 44. At 2800 with the Vcan it could be 50* and all-in, with the Vcan, it could be 56*, and to that I can add up to 6 more with the dial-back.

The dial back is also great for starting because with it, I can take 9* out during cranking so it cranks on 5*. Then as soon as it starts (cold) I can dial all 15 back in for 20* at idle, during the warm up, so no choke is needed. Then, after the warm up, I take the 6 out again, and leave it alone. All from the saddle.

If you need more power below stall, the right thing to do is increase the cylinder pressure.

If you need more power at low speed then you need a higher stall.

If the power sucks all the time in first gear, you need a bigger number rear gear. Or a bigger engine.

If you just need a lil more power at Part Throttle and low speed, get more timing from the Vcan.

My stocker made 22*. @TrailBeast got 24* out of his. Just map out at what throttle opening yours starts dropping off, and run in the zone, for max torque. I installed a vacuum gauge on the signal line, to tell me where I was on the throttle. Easy-Peasy.

BTW

I run that one-long loop 318 spring and it is what helps my combo run 87E10 at 11/1 Scr; by delaying my "all-in" to ~3400rpm.

The little one gets me 28*@2800 starting from 14* initial at about 900/1000rpm. Great curve for my combo. Yes it had more torque with more low-rpm timing, but if smokes the tires just the same with less timing,lol.

My V-can brings 22* to the table any time the throttle is reduced. By 1600 or so, at PT, the timing is getting to be over 40, and by 2000, it could be as high as 44. At 2800 with the Vcan it could be 50* and all-in, with the Vcan, it could be 56*, and to that I can add up to 6 more with the dial-back.

The dial back is also great for starting because with it, I can take 9* out during cranking so it cranks on 5*. Then as soon as it starts (cold) I can dial all 15 back in for 20* at idle, during the warm up, so no choke is needed. Then, after the warm up, I take the 6 out again, and leave it alone. All from the saddle.

Last edited:

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,636

- Reaction score

- 13,870

yes; at the crank that would be 17*

Dartfreak75

Restore it, Dont part it!

Multiply that by 2 to get your total mechanical advance.Post #29. Pic shows 8.5 on the T piece. That is cam degrees, not crank degrees, Correct?

-

Similar threads

- Replies

- 28

- Views

- 5K

- Replies

- 5

- Views

- 895

- Replies

- 1

- Views

- 1K