i run factory upgraded parts , bigger t bars frame connectors QA-1 2 way adjustable shocks and big sway bars front and back does fine on back roads and the track , Suspension mods are verboten in Quebec so am stuck using factory parts . Car is tons of fun have no trouble keeping up with new cars , many of the parts are from Bergman , great guy to deal with

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DOES THE HDK SUSPENSION K-MEMBER HANDLE BETTER THAN A T-BAR SUSPENSION?

- Thread starter racerjoe

- Start date

-

Dale Davies

Well-Known Member

Randy was running in about 74, so the aftermarket parts were not available like now. I think he put a big block anti roll bar on but still had a fair bit of body roll mid corner. The only way to get camber gain would have been to do a Shelby style UCA relocation 1" lower, like was done on the Shelby Mustangs. Much more difficult on the A body Mopar vehicles.I run .5 neg camber. I've found two things. One, more negative camber directly affects tracking over poor surfaces. Second, in my setup the camber gain is good enough that I don't need all that negative static camber. I do run 7.5 degrees caster, taller upper ball joint and F spindles.

Last edited:

Dale Davies

Well-Known Member

A little bit nanny state like Germany with their TUV. Can not put wider tires on than came on the car.i run factory upgraded parts , bigger t bars frame connectors QA-1 2 way adjustable shocks and big sway bars front and back does fine on back roads and the track , Suspension mods are verboten in Quebec so am stuck using factory parts . Car is tons of fun have no trouble keeping up with new cars , many of the parts are from Bergman , great guy to deal with

This is simple actually. Hence the taller spindle and ball joint.Randy was running in about 74, so the aftermarket parts were not available like now. I think he put a big block anti roll bar on but still had a fair bit of body roll mid corner. The only way to get camber gain would have been to do a Shelby style UCA relocation 1" lower, like was done on the Shelby Mustangs. Much more difficult on the A body Mopar vehicles.

His duster had shims for the upper control arm?I would take it your specification of 1.5° camber would be negative.

A friend decided to road race his Duster after a tiff with the drag racing bunch. Upgrsded the front brakes to factory discs and a few other things like an AC water pump. I suggested increasing the caster and starting with 1° negative camber. He could out accelerate a race prepared Sunbeam Tiger on the straight but got passed at the corner. Most corners were right hand so the left front tire pretty much melted the outside two ribs. I tried to get him to pull about 1/4" of shims out of the upper adjustment, but he said his alignment guy knew what he was doing. Obviously not. Pull the shims out and reset toein and good to go, but no dice. Cost him on tires through that summer as the left front had to be replaced after every race weekend.

At the end of the summer he refreshed the engine with rings, bearings and timing chain. Sold it to a kid whose father was a hotshot lawyer. Kid blew the engine within a week. He told the kid the engine had been refreshed but did not put on the bill of sale "no warranties expressed or implied". Had to give the kid back the full purchase price and then find another 340 engine. Kid had missed a shift big time and scattered parts all over the road.

Makes sense why you shouldn’t share mounting points and such. No argument there.

But things like a potential roll center, camber gain, scrub radius, wheel rate, etc. are all easy to calculate and validate (or invalidate) a design and make it easier to compare to other designs. Like comparing CD on different makes of cars, doesn’t expose the design but it gives hard numbers to compare when one design says “better aerodynamics“.

Certainly things like ride height, alignment and wheel/tire sizes can have a huge impact on those numbers making an apples to apples comparison hard. But honestly, if I was marketing a kit as having better geometry, first thing I would do is drag in a stock car, standarize those values and take some measurements. Then I would set up my kit the same way and if they were improved I would publish them every place I could. But I don’t see anyone doing that which makes me wonder…

I understand that you aren’t making that claim, not pointing this at you. But there are other companies that do make that claim, without anything to back it up. And based on the OP’s initial set up, I would bet at the very least the roll center is not better on those other kits.

It’s not like the stock suspension has to be all that modified either. Toss on an adjustable UCA and leave the rest alone. Bolt up a 17” or 18” tire similar to what the COC would run and match the ride height. Then give it an alignment of something like -0.5 camber and +6 caster and take measurements of the pivot points. Then cycle the suspension and measure the camber gain. With that someone would have a baseline and could set up a COC with the same values and take the same measurement and actually see if their suspension had better geometry.

I understand why they don’t though. Most people in the community believe a COC is better, so why spend time and money to prove it when it might not be true and it’s already generally accepted.

What I think you are missing is on OEM or aftermarket, there are sooooo many variables that one size (setting) will NEVER fit all. HDK offers two spindle heights and 3 different shock settings. Add that to not everybody has the same size front tire or preference in ride height. there could be a 4-5" difference in ride height alone. I will make the claim again....HDK has MORE out of the box adaptability than ANY set-up to accommodate individual needs and preferences. The fine-tuning of any package (as with other components) has always been up to the skill level of the installer and available components.

And don't forget to add several other factors like different applications, not to mention the skill, comprehension and knowledge level that changes with every individual.

for example.....I have had more than one call asking why their new front suspension is now stiff.....My first question is "what setting (compression / rebound) are your shocks on? and guess what their answer is?..."I have no idea".

Another good one.... it has been a while but I had one customer tell me he was not impressed with the way the car now drives. To be honest, and after over a decade of satisfied customers, I was surprised because I had NEVER heard that before. My first question was..."what alignment specs did you use?...and the reply...."I have not aligned it yet".

....and then you have the other side....Tim aka Race Joe, 72 Blu Blu, Peter Bergman and others all filled with extensive knowledge, not to mention skill

Please don't be too critical. Every one of us began because of our personal needs, the fact that others wanted us to build them a similar platform (regardless of each individual perfect roll center) has been a plus to the Mopar hobby.

Last edited:

Dale Davies

Well-Known Member

I can not remember. It may be the cam washers. Bottom lineHis duster had shims for the upper control arm?

is he needed to move the UCA in about 1/4".

DionR

Well-Known Member

What I think you are missing is on OEM or aftermarket, there are sooooo many variables that one size (setting) will NEVER fit all. HDK offers two spindle heights and 3 different shock settings. Add that to not everybody has the same size front tire or preference in ride height. there could be a 4-5" difference in ride height alone.

And don't forget to add several other factors like different applications, not to mention the skill, comprehension and knowledge level that changes with every individual.

Certainly every car is going to be different and the final setup is going to have significant differences. And no, not every end user has the same goal, skill or knowledge. Nope, not missing there is a huge spread of options and setups.

That’s why I suggested fixing the variables. If someone is going to claim better suspension geometry and handling, then they should be able to find a common “handling” setup for a TB suspension, setup their suspension to match and remove as many variables as possible and then show the comparison results.

Not so they can say every car with this suspension will have these results, but so they can show actual differences. Comparable numbers, not just sales taglines.

Otherwise the claim is made up.

Please don't be too critical.

I’m not being critical of you, don’t take this as something really pointed at you in any way. I know you are the manufacturer of this kit, but I understand that you didn’t get into this market for better geometry or handling nor do you claim that. But others do claim better geometry and handling and I am just pointing out that it wouldn’t be hard for them to back up their claims.

Every one of us began because of our personal needs, the fact that others wanted us to build them a similar platform (regardless of the perfect roll center) has been a plus to the Mopar hobby.

Absolutely, I agree it is a plus. Not suggesting that everyone should care about their roll center.

What does annoy me though is a company (again not you) that makes a claim about better handling without any support. I am annoyed by it because most of those same guys you mention that can’t even get an alignment or setup the shocks run around telling everyone how much better the car handles because the company they bought it from said so. And most of those guys never even drove the car stock let alone with a suspension that wasn’t worn out. And then even the knowledgeable guys start parroting this claim. All without anything more than “the website claims better handling”.

I will add though, that if Joe hadn’t put the time and effort to further refine your kit I don’t think he would have made an improvement to the handling of his car. I am sure it would have worked fine, it certainly will make the G3 swap easier. But at its initial baseline install I am of the opinion that handling was probably worse.

And I think that his current setup probably isn’t significantly better than his old one with a set of 1.12 TB’s and a set of adjustable shocks. But just my gut feel.

What I am jealous of though is the sealed bearing and hub with at least the potential of an integrated wheel speed tone ring.

I will add though, that if Joe hadn’t put the time and effort to further refine your kit I don’t think he would have made an improvement to the handling of his car. I am sure it would have worked fine, it certainly will make the G3 swap easier. But at its initial baseline install I am of the opinion that handling was probably worse.

And I think that his current setup probably isn’t significantly better than his old one with a set of 1.12 TB’s and a set of adjustable shocks. But just my gut feel.

What I am jealous of though is the sealed bearing and hub with at least the potential of an integrated wheel speed tone ring.

That is the number one reason Tim was picked for the HDK. I had been following Tim for years and gathered he is one of the last guys I would expect to leave anything "out of the box". His performance resume and his Duster including the evolution of it..... speak for themselves.

And what did Tim change from out of the box HDK other than alignment specs? ....I made him a different sway bar (same material / size) bent for tire clearance and he added an additional 1" to the upper ball joint stud. The long list of changes appear to be what he did to his OEM suspension BEFORE the HDK install.

The point of my handing a HDK to Tim and this thread is simply to shed light on the never ending question....with data to back it. And it was important to me that the data came from someone as independent as possible and preferably one of us (FABO).

And lastly, could you provide me with any evidence of your claims????....otherwise (to quote you) the claim is made up.......

How about staring with these two dandy's....."I will add though, that if Joe hadn’t put the time and effort to further refine your kit I don’t think he would have made an improvement to the handling of his car. I am sure it would have worked fine, it certainly will make the G3 swap easier. But at its initial baseline install I am of the opinion that handling was probably worse.

And I think that his current setup probably isn’t significantly better than his old one with a set of 1.12 TB’s and a set of adjustable shocks. But just my gut feel."

Did you see the list of things he did to his OEM suspension BEFORE the HDK install?????....lets refresh from page 1 of this thread

My t-bar setup consisted of the following parts.

- Sway a way 1.08 bars

- Hotchkis front and rear sway bar, non-adjustable shocks, and leaf springs

- SPC gen 1 upper control arms

- FMJ Spindles

- Aluminum tie rod sleeves

- QA1 adjustable strut rods

- Fully welded biscuit type K-member and LCAs

- Borgeson steering box

- 14” front discs and 12” rear discs

- Falken Azenis 200TW 235/40-18 front tires, 275/35-18 rear tires

- Alignment- 6.25 degrees caster, 1.5 degrees camber

Just trying to keep it real....

Last edited:

Or change the camber curve.I can not remember. It may be the cam washers. Bottom line

is he needed to move the UCA in about 1/4".

DionR

Well-Known Member

That is the number one reason Tim was picked for the HDK. I had been following Tim for years and gathered he is one of the last guys I would expect to leave anything "out of the box". His performance resume and his Duster including the evolution of it..... speak for themselves.

...

The point of my handing a HDK to Tim and this thread is simply to shed light on the never ending question....with data to back it. And it was important to me that the data came from someone as independent as possible and preferably one of us (FABO).

Completely agree. Absolutely he was the right choice. He certainly isn't going to leave things as "out of the box" and he is going to be honest about his assessments as well. I think you picked a winner and found someone that will help you make your product better.

And what did Tim change from out of the box HDK other than alignment specs? ....I made him a different sway bar (same material / size) bent for tire clearance and he added an additional 1" to the upper ball joint stud. The long list of changes appear to be what he did to his OEM suspension BEFORE the HDK install.

Big thing was calculating the roll center and adding an even longer ball joint. You shipped it with the 1" longer than stock ball joints, that's "out of the box". Out of the box with the known and "traditional" parts for your kit put the roll center underground and had a less than favorable camber gain.

No one that I know of has spent the time to find and validate a 2" longer ball joint which had a significant improvement on at least the roll center if not the camber gain. I don't see how you can call that out of the box, best I can tell it wasn't even on your radar to suggest it.

I'm not suggesting it is in the same league as having to cut and reweld stuff, but it's not out of the box either. If it is, then aftermarket control arms, strut rods and stiffer torsion bars are "out of the box" as well.

And lastly, could you provide me with any evidence of your claims????....otherwise (to quote you) the claim is made up.......

How about staring with these two dandy's....."I will add though, that if Joe hadn’t put the time and effort to further refine your kit I don’t think he would have made an improvement to the handling of his car. I am sure it would have worked fine, it certainly will make the G3 swap easier. But at its initial baseline install I am of the opinion that handling was probably worse.

Let me start by saying I am reading between the lines and forming an opinion. So not a hill I am going to die on but let me give some idea of why I feel that way.

To further clarify the above comment, I think if Joe had put your suspension in with non-adjustable shocks and the 400# springs, I think he would have found it was less than what he had before because the roll center would cause him issues. The rest of the suspension would have been close to an apples to apples (about the same wheel rate and style shock) but the roll center being under ground would be a fair negative.

12:05 Garage- ’70 Duster build

I believe at some point the retractable mechanism was recessed into the rear panel, not on exposed on the floor. Perhaps this was in 73 when they changed the interior panel design to plastic?? It was '74 when they changed it. Still had a retractor on the floor for the lap belt segment, but...

www.forabodiesonly.com

www.forabodiesonly.com

In this post Joe was about even with the Cobra he couldn't beat before. That's after upping his wheel rate with the 450# springs and adding adjustable shocks but before fixing the roll center. Hard to say but I lean in the direction that the stiffer springs and adjustable shocks were the source of the increase and had little to do with the new suspension. And the degradation of the suspension geometry cost him some of that increase (see below).

And I think that his current setup probably isn’t significantly better than his old one with a set of 1.12 TB’s and a set of adjustable shocks. But just my gut feel."

12:05 Garage- ’70 Duster build

Denny, I'm not "bitching". You made some comments about bump steer on these cars with factory suspension that are in fact not accurate. I know that for a fact because I've literally done the EXACT things you said would cause bump steer. And they don't. And frankly that shouldn't be that...

www.forabodiesonly.com

www.forabodiesonly.com

And then in this post, he beat the guy in the Cobra (same guy? not certain) after fixing the geometry issue. I think the only real improvement was the geometry and more seat time.

So now he has a suspension with double adjustable shocks and stiffener springs along with a roll center that is at least close to the TB suspension. Unfortunately, that isn't an apples to apples comparison and makes it harder to say which made the most difference. So now we have to make guesses and my guess is that the springs and shocks make a good difference and the same change to the TB suspension would have resulted to at least the same if not a little more improvement. Maybe a little better only because I don't think the modified roll center is yet as good as the TB setup was.

The other thing I noticed is the attitude the car has in the corners from this years Moparty. I tried to go back and compare them to pictures with the TB suspension and couldn't find anything definitive as it was hard to find pictures in the same place in a corner and such. But it sure looks to me that the car has a good more roll in the corner with the COC verses the TB suspension. Note that this is before the geometry fix from the taller UBJ.

Did you see the list of things he did to his OEM suspension BEFORE the HDK install?????....lets refresh from page 1 of this thread

My t-bar setup consisted of the following parts.

- Sway a way 1.08 bars

- Hotchkis front and rear sway bar, non-adjustable shocks, and leaf springs

- SPC gen 1 upper control arms

- FMJ Spindles

- Aluminum tie rod sleeves

- QA1 adjustable strut rods

- Fully welded biscuit type K-member and LCAs

- Borgeson steering box

- 14” front discs and 12” rear discs

- Falken Azenis 200TW 235/40-18 front tires, 275/35-18 rear tires

- Alignment- 6.25 degrees caster, 1.5 degrees camber

Confused, I've never said the TB suspension didn't need mods. Straw man?

BTW, I hope you do not confuse claiming better handling claims in the context of adding a sway bar as false.

Nope.

Hey DionR

Our opinions obviously vary and I see no value in going back and forth getting this thread off track. I do value the fact that you are just searching for the perfect set-up. All good IMHO!!!

Denny

Our opinions obviously vary and I see no value in going back and forth getting this thread off track. I do value the fact that you are just searching for the perfect set-up. All good IMHO!!!

Denny

Dale Davies

Well-Known Member

Changing the camber curve usually involves relocating something. 50 years ago taller spindles to raise the upper ball joint were not readily available. Maybe spindles from a full size car or truck could work.Or change the camber curve.

The easy way on early Mustangs was to drill the UCA pivot bolt holes 1" lower. Inexpensive and functional to change the camber curve to gain negative camber to offset body roll. The Mustang 2 front suspension is not so easy. Those with cams to adjust camber would require cutting the mount off the frame and welding it back on lower.

Today there are a few options available for camber and bump steer correction.

Just money.

Longer upper ball joints.Changing the camber curve usually involves relocating something. 50 years ago taller spindles to raise the upper ball joint were not readily available. Maybe spindles from a full size car or truck could work.

The easy way on early Mustangs was to drill the UCA pivot bolt holes 1" lower. Inexpensive and functional to change the camber curve to gain negative camber to offset body roll. The Mustang 2 front suspension is not so easy. Those with cams to adjust camber would require cutting the mount off the frame and welding it back on lower.

Today there are a few options available for camber and bump steer correction.

Just money.

DionR

Well-Known Member

Hey DionR

Our opinions obviously vary and I see no value in going back and forth getting this thread off track. I do value the fact that you are just searching for the perfect set-up. All good IMHO!!!

Denny

But isn’t this thread about exactly what we are talking about? At least we aren’t in Joe’s build thread anymore.

Either way, I am ok agreeing to disagree.

Dale Davies

Well-Known Member

And 50 years ago those were not available.Longer upper ball joints.

Another issue is longer tie rods to correct bump steer. My brother in law had an 05 Mustang for track days that had those for bumpsteer correction. After 17 years he was in a turn at about 70 MPH when the outside ball joint for the tierod broke. The organizing club does scrutineering on the vehicles and my brother in law regularly checked the steering and brakes. No external cracks were noted prior to the failure.

Moral of the story is, if you use longer ball joints or tierod ends, have them magnaflux tested every couple of years and probably every year after 8 years use.

I helped with chassis setup on a 48 Merc pickup. We held the rack in place with c clamps and then jacked it up and down with no springs to check toe change. This way we could measure and minimize toe change. We had to order spacers for the inner tierod ends to get the pivot point centered along the line between the LCA and UCA pivot points. We yhen double checked bumpsteer before welding the rack mounts in place. This is a street driver so camber gain was not a consideration.

Lower the front end.And 50 years ago those were not available.

Another issue is longer tie rods to correct bump steer. My brother in law had an 05 Mustang for track days that had those for bumpsteer correction. After 17 years he was in a turn at about 70 MPH when the outside ball joint for the tierod broke. The organizing club does scrutineering on the vehicles and my brother in law regularly checked the steering and brakes. No external cracks were noted prior to the failure.

Moral of the story is, if you use longer ball joints or tierod ends, have them magnaflux tested every couple of years and probably every year after 8 years use.

I helped with chassis setup on a 48 Merc pickup. We held the rack in place with c clamps and then jacked it up and down with no springs to check toe change. This way we could measure and minimize toe change. We had to order spacers for the inner tierod ends to get the pivot point centered along the line between the LCA and UCA pivot points. We yhen double checked bumpsteer before welding the rack mounts in place. This is a street driver so camber gain was not a consideration.

racerjoe

Well-Known Member

I'm happy you finally chimed in Peter! @BergmanAutoCraft . Our discussion at Moparty is what influenced me to educate myself about camber curves, roll center, roll couple, etc. Talk about a stand up guy helping someone with a competitors product to become better. While there are plenty of people in the hobby with this mindset, we need more.I'm very late to this party. Tim is a great guy with a nice car too! He mentioned some good points, especially regarding the camber curves. I have some comparison photos on my phone I can add. You will never get an apples/apples comparison. Its like saying my new tires are better than my old ones.

I think the things to take home here are people like a clean bolt in solution with all new parts, regardless of what they do. Others are happy with getting dirty and doing modifications.

In terms of performance, the tires don't care where they get their angles or spring rate from. Excellent performance can be achieve many ways these days.

The things I like about my t bar setup is a good ride, turning radius and suspension travel. My setup uses delrin bushings which last almost forever. The room for tires is huge with 18s. I've run a 275 on the front pretty easily. My on center feel is excellent and the on center tracking is easily as good and my modern cars. The tires remain square throughout the turns maximizing the contact patch. I realize most won't go through the lengths I have to setup and refine like I have, but the results are impressive.

For anyone looking to compare lap times, that's another story entirely. Driving skill and tires are very big factors. Personally, I'm not the greatest driver, and I like to run tires I can use in any temp. Currently running Michelin Pilot Super Sports. 320 TW.

The biggest take away is be thankful there are options. I started navigating handling improvements in 1985, when it was just a joke..

racerjoe

Well-Known Member

I started with 400lb springs. Changing to the 450lb was a "knee jerk" reaction to trying to solve the body roll issue. Now I know the problem wasn't spring rate or sway bar size, it was the long roll couple. While I was making the adjustments, Denny and I discussed making a bigger sway bar. I wanted to hold off to see how the geometry changes affected the body roll. As it turns out, I think the standard bar is fine. Now physics is handling body roll as opposed to springs and sway bar. The 400lb springs may be fine, but I'm not changing them out because I haven't felt any feedback from the car that would indicated it being over sprung.Sure enough, you did. Looks like your 450# springs are about the same rate as a 1.12 TB which is up from the 1.08 bars you were running before the change.

I was just curious if the spring rate had been maintained between the 2 setups. Just a data point.

DionR

Well-Known Member

I started with 400lb springs. Changing to the 450lb was a "knee jerk" reaction to trying to solve the body roll issue. Now I know the problem wasn't spring rate or sway bar size, it was the long roll couple. While I was making the adjustments, Denny and I discussed making a bigger sway bar. I wanted to hold off to see how the geometry changes affected the body roll. As it turns out, I think the standard bar is fine. Now physics is handling body roll as opposed to springs and sway bar. The 400lb springs may be fine, but I'm not changing them out because I haven't felt any feedback from the car that would indicated it being over sprung.

I wouldn’t go backwards either.

J-c-c

Well-Known Member

Since I believe I might have been the first to voice my disappointment of not having IFS manufacturer measurements shared, let me recap a few key points:

1. All key measurements can be made by a purchaser ultimately

2. The main concern when doing so however IMO is accuracy

3. In my case it was needed after purchase and paid, for a $6K+ IFS

4. And was offered with a signed NDA, non-disclosure agreement, to meet the sellers concerns if needed

5. This would speed things up only tuning for my car and its parameters using owned suspension software programs.

Best thing to prevent someone from copying your product is don't build it, or design it poorly.

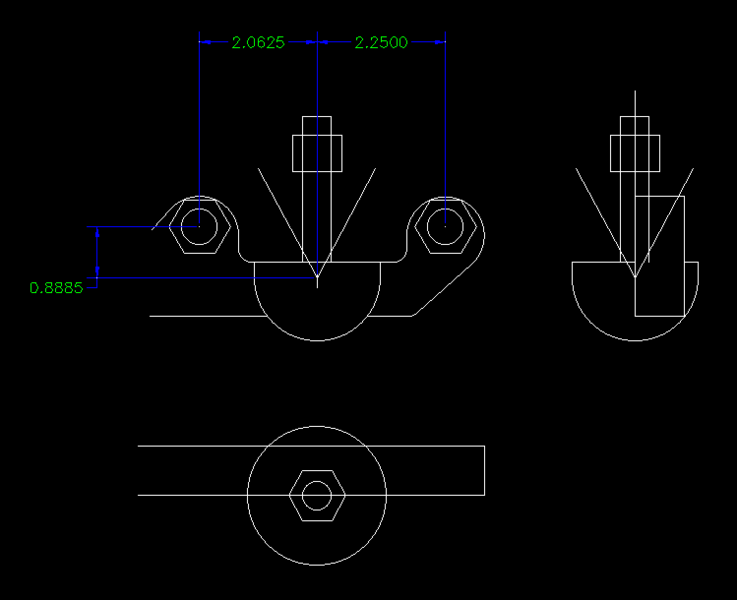

Speaking of RMS, here are my upgrade's that IMO addressed areas I felt needed some simple and little weight gain improvements, that gained some measurable stiffness improvements, and with the weight penalty of less than 10lbs, and all had below the COG. There is more here that this Pic doesn't show, for instance the shock/spring towers are fully boxed now.

This was built about 10 years ago, and I had it cyro'd before power coating, to help mitigate all the welding added.

1. All key measurements can be made by a purchaser ultimately

2. The main concern when doing so however IMO is accuracy

3. In my case it was needed after purchase and paid, for a $6K+ IFS

4. And was offered with a signed NDA, non-disclosure agreement, to meet the sellers concerns if needed

5. This would speed things up only tuning for my car and its parameters using owned suspension software programs.

Best thing to prevent someone from copying your product is don't build it, or design it poorly.

Speaking of RMS, here are my upgrade's that IMO addressed areas I felt needed some simple and little weight gain improvements, that gained some measurable stiffness improvements, and with the weight penalty of less than 10lbs, and all had below the COG. There is more here that this Pic doesn't show, for instance the shock/spring towers are fully boxed now.

This was built about 10 years ago, and I had it cyro'd before power coating, to help mitigate all the welding added.

Last edited:

DionR

Well-Known Member

If anyone wanted to measure their ball joint locations and calculate a roll center on their TB suspension, here are some dimensions for the lower ball joint that might make it easier to find the actual pivot location.

The idea being that maybe it would be easier to measure to one of the BJ mounting bolts, and then calculate the actual pivot location. So width wise the BJ aligns with the back of the nut and is about 7/8" below the center of the bolt. Note that caster will change this some as the front and back bolts probably aren't at the same elevation, but I bet it won't matter a whole lot. Same thing with the toe, but again probably not much variation.

So, get a horizontal dim off the end of the bolt and add whatever the bolt sticks out past the nut plus the thickness of the nut. Then get an elevation to the center of the bolt and subtract 7/8".

Also, I did the best I could to measure things, but the numbers probably aren't perfect. But they should be close.

The idea being that maybe it would be easier to measure to one of the BJ mounting bolts, and then calculate the actual pivot location. So width wise the BJ aligns with the back of the nut and is about 7/8" below the center of the bolt. Note that caster will change this some as the front and back bolts probably aren't at the same elevation, but I bet it won't matter a whole lot. Same thing with the toe, but again probably not much variation.

So, get a horizontal dim off the end of the bolt and add whatever the bolt sticks out past the nut plus the thickness of the nut. Then get an elevation to the center of the bolt and subtract 7/8".

Also, I did the best I could to measure things, but the numbers probably aren't perfect. But they should be close.

DionR

Well-Known Member

Since I believe I might have been the first to voice my disappointment of not having IFS manufacturer measurements shared, let me recap a few key points:

1. All key measurements can be made by a purchaser ultimately

2. The main concern when doing so however IMO is accuracy

3. In my case it was needed after purchase and paid, for a $6K+ IFS

4. And was offered with a signed NDA, non-disclosure agreement, to meet the sellers concerns if needed

5. This would speed things up only tuning for my car and its parameters using owned suspension software programs.

Best thing to prevent someone from copying your product is don't build it, or design it poorly.

Speaking of RMS, here are my upgrade's that IMO addressed areas I felt needed some simple and little weight gain improvements, that gained some measurable stiffness improvements, and with the weight penalty of less than 10lbs, and all had below the COG.

View attachment 1716196563

So you have numbers for the RMS, or maybe will in the future?

J-c-c

Well-Known Member

FWIW, Ron Sutton says any measurements that are >1/8" off in measurements, pretty much makes all calculations meaningless. less than 1/16" should be the goal he suggests for the DIY tuner. This was shared at one of his in-depth seminars that covered this topic years back.

Ron Sutton Race Technology :: Hardcore Parts & Tech Support

Ron Sutton Race Technology :: Hardcore Parts & Tech Support

J-c-c

Well-Known Member

Future I hope.So you have numbers for the RMS, or maybe will in the future?

-

Similar threads

- Replies

- 27

- Views

- 780

- Replies

- 21

- Views

- 761

- Replies

- 9

- Views

- 367

- Replies

- 42

- Views

- 2K

- Replies

- 7

- Views

- 402