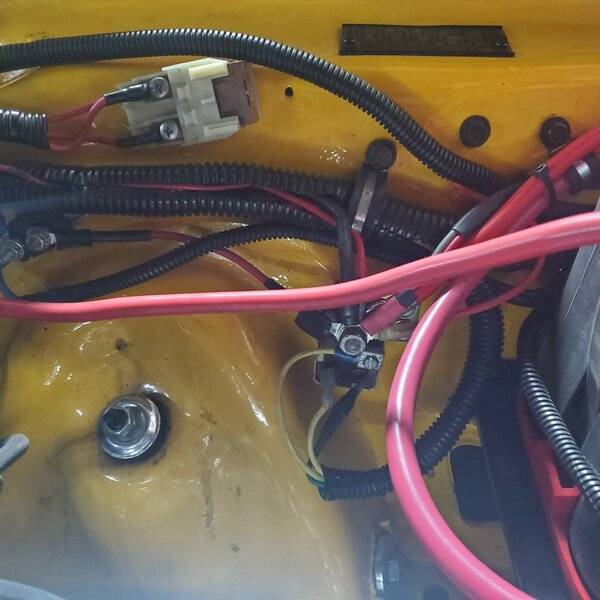

Prior owner of my car installed a Painless harness for the entire car... then went off the reservation. I've been kinda turning a blind eye to the issues I've seen as everything works for now. Want to add a pre-amp for the stereo into the trunk and I've finally decided I cannot stand the rats nest of unfused and improperly fused circuits. The 12v post on the starter relay is currently being used as the 12v "gang" post for most of the mess. See photo below:

There is a circuit breaker to the left of the relay I believe was for the fans. And that 75A "mega" fuse above and to the left of the starter relay that came with the painless kit. I'm absolutely positive those tiny wires attached to it would melt to the fender at less than half that amperage... just one of many WTF items I've noted. I've already installed an inline fuse to the alternator charging circuit and will eliminate the 2 other circuits coming off the alternator. Plan is to get everything off that relay post and onto a fused bus bar fed from the battery. So the million dollar question... does that post on the starter relay need 12v or can it be bypassed completely?

There is a circuit breaker to the left of the relay I believe was for the fans. And that 75A "mega" fuse above and to the left of the starter relay that came with the painless kit. I'm absolutely positive those tiny wires attached to it would melt to the fender at less than half that amperage... just one of many WTF items I've noted. I've already installed an inline fuse to the alternator charging circuit and will eliminate the 2 other circuits coming off the alternator. Plan is to get everything off that relay post and onto a fused bus bar fed from the battery. So the million dollar question... does that post on the starter relay need 12v or can it be bypassed completely?