Hi all. Happy Thanksgiving! Question; ive read that angle milling big block hi po exhaust manifolds will make them fit a Big blockA body swap? If so, does anyone know for sure how much to mill off and which bolts/ studs to mount them? After milling I figured the holes would be out of alignment. I’m using edelbrock rpm heads and a B engine. Which obviously has the lower deck height. Thanks in advance for any help! Mark

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

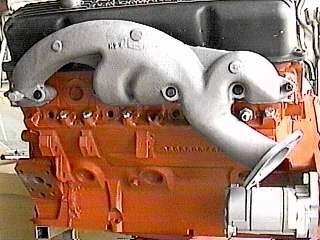

Exhaust manifolds

- Thread starter cuda620

- Start date

-

4mulas

Fixem'up

I don’t think this is possible. The outlets leg on the left side is completely different, don’t think any amount of milling will make it workable…

a body

the top manifold is drivers side in both pictures

b body

a body

the top manifold is drivers side in both pictures

b body

Mark, I have milled the C body drivers side 1/16 on the angle. If u go anymore the flange will hit the block. The B body will fit without milling but u have to shorten the steering column housing to the firewall. U could have the b body milled if u wanted. Kim

Yes they are off a bit. I had a thick flat washer milled on the angle. Then I super glued them to the manifold. This trick only works once. I have friends that just used the factory stuff or header bolts and they seemed to work fine. Kim

The 68 and 69 B body manifolds will fit good with the low deck in a 67 and up A body. You'll need to cut the steering column housing about even with the firewall and do away with the column shifter mechanism and convert to floor shift. The C body HP manifold also will fit. That's the one that sometimes requires milling so that the outlet is closer to the engine. The passenger side B body HP manifold pretty much just falls in. With the RB engine like a 440, People have also made those fit, but it starts getting pretty dang tight.I read from someone named Kimmer that it would. I’m not gonna spend the money that’s wanted for oem’s. Thanks, Mark

1968rt

Well-Known Member

- Joined

- Jan 2, 2008

- Messages

- 150

- Reaction score

- 210

Trim the column, cut an access hole for #6 plug and it will fit fine, no milling and even with power steering and a 440!

Last edited:

I think c body hp manifolds come forward at the back. That would eliminate that problem.

Yup, makes a big difference.

1968rt

Well-Known Member

- Joined

- Jan 2, 2008

- Messages

- 150

- Reaction score

- 210

From what I recall a C Body drivers side will cost you at least 5-7 HP. An original A body BB Drivers side will cost you about 12HP. There was an aftermarket drivers manifold that looked like an original A body without the restriction. Made by Accurate.

pishta

I know I'm right....

I angled milled a Hi-po drivers side manifold just a few degrees and it fit a 400 in a NARROW 65! The only reason you need to do this is to get the steering shaft to clear the manifold. In a 67 or newer I don't think this is even needed. This was after I shimmed the mounts as far over to the passenger side as I could and even slotted the steering box bolt holes about 2mm. I studded 5th manifold bolt and bent it down a little so the nut would go on flush. I would machine the steering shaft down about 2mm if I had to do it again and run solid motor mounts again. The Accurate manifold did not have the steering clearance, makes you wonder why the original had to have it.

I had the factory studs on my 383 builds. Kim

1968rt

Well-Known Member

- Joined

- Jan 2, 2008

- Messages

- 150

- Reaction score

- 210

You shouldn't hit the fire wall on the drivers side. What motor mounts are you using? I used the Schumacher mounts and you could turn them 90 or 180 degrees.

-

Similar threads

- Replies

- 1

- Views

- 422

- Replies

- 20

- Views

- 1K

- Replies

- 8

- Views

- 663

- Replies

- 7

- Views

- 1K