Chrysler had a couple ways of reducing the maximum current that might have to go through the bulkhead connector. They did this on cars with leece-neville and Chrysler 60/65 amp alternators. And/or also on later A-bodies with rear window defroster grids.

The basic concept is the same on all of them.

a. Run a heavier wire from the alternator through a grommet in the firewall.

b. Split the maximum load. Usually this was done by keeping the standard wiring path through the bulkhead while having a second path for charging the battery.

A simple version of that is a parallel alternator output wire going to the ammeter.

The orange arrows represent current flow if the battery was getting recharged at the same time the lights and wipers were on.

This arrangement only requires one fusible link.

Because my b'cuda has an MSD, you'll see in the finished photo the single terminal junction is also used for the main power to the MSD 6T.

This way the ammeter only shows power into or out of the battery.

It also connects the MSD power closer to the power source.

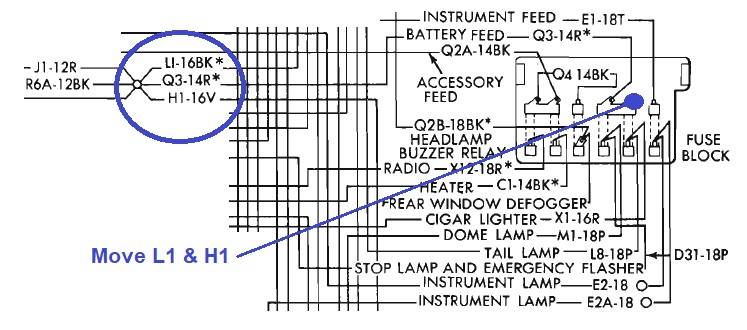

I got the idea from this optional '73 B-body scheme.

If you're replacing the engine side harness then this is another option.

In my case I decided I didn't want to unwrap the existing harness. That was the main reason I added a second parallel wire from the alternator.

I dont see a need for you to be running 6 ga wires between battery and the terminal block. But notice they protected the 6 ga with a 10 ga fusible link. Then they protected the 10 and 12 gage wires inside the car with a 16 ga fusible link.

Plenty now for you to think about!

One more suggestion for reducing the maximum current through the bulkhead connector. If you'll be driving at night, add a headlight relay system. Power it from the alternator. These cars came with 40 W/50W headlights (6012 bulbs), the headlight routing is long, and the wiring is small (16 gage to the hi/lo 18 ga to the lamps). Dan Stern will sell you a kit. Crackedback sells ready made harnesses. I made my own, but both of those guys provide quality stuff.

ered together and using the vacant fuse post? See the picture...

ered together and using the vacant fuse post? See the picture...