moparmat2000

Well-Known Member

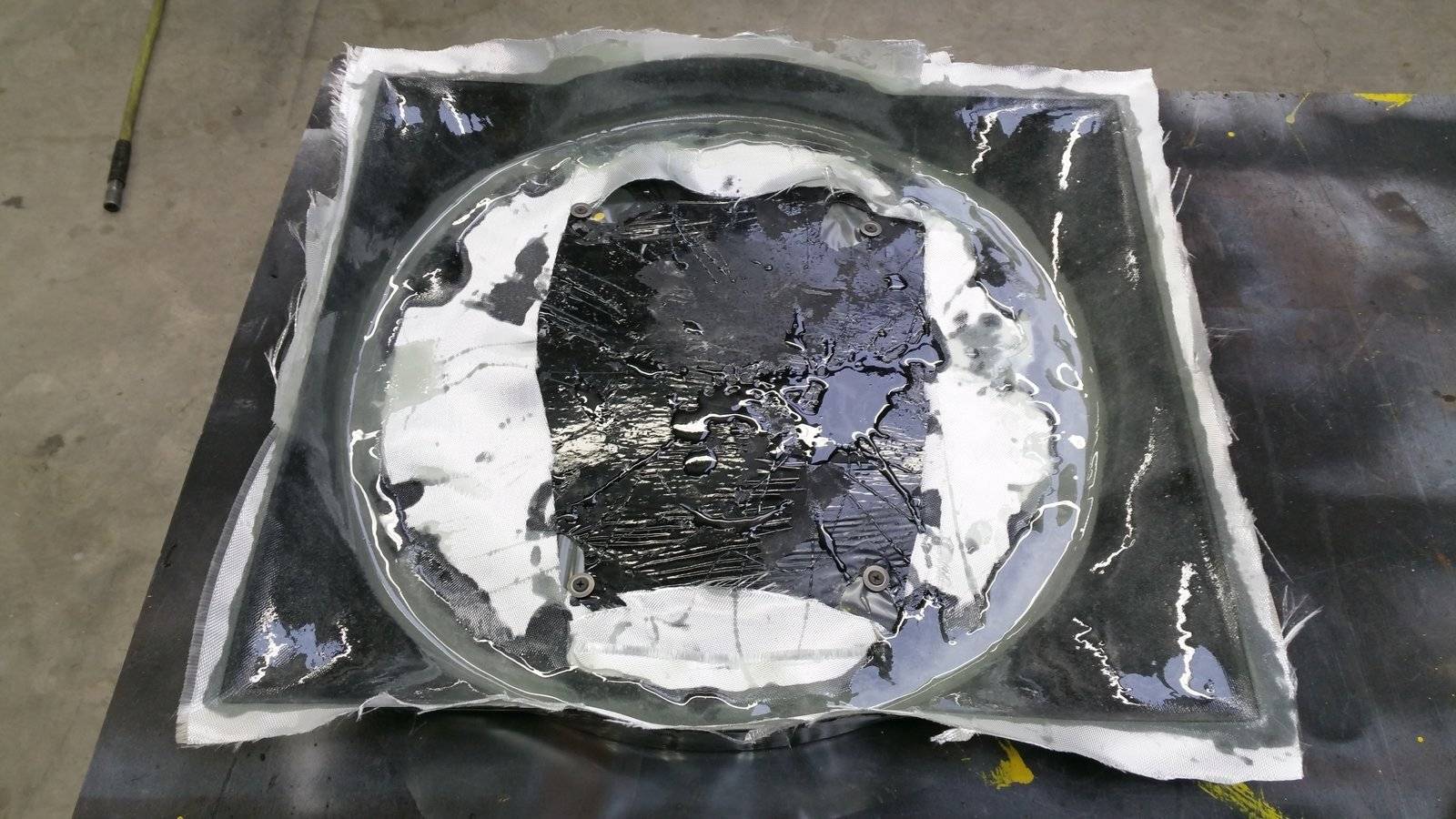

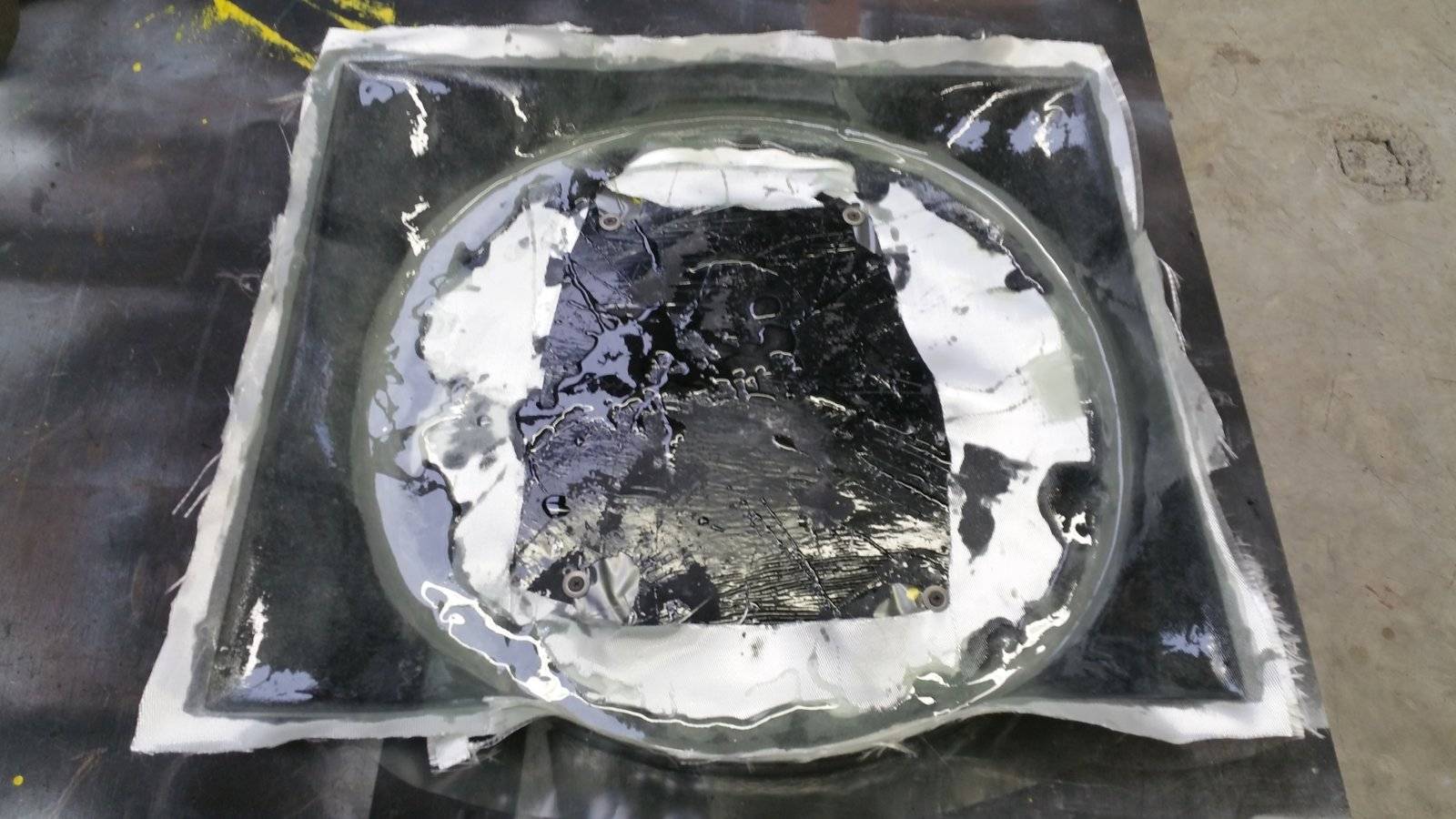

Ok as promised. Heres pix. I put 3 layers of 7781 style fiberglass (think looks like burlap) on the shroud in all the reinforcing points, and just 2 layers in the rest. When it dries i plan on trimming the excess, and cutting out the fan hole. For now its screwed down to the table top until it dries just in case it decides it wants to twist. Once its cut out i will see if it will need more reinforcing or not, and i will start on making my mounting tabs. If you notice the gray color where the circle is thats going to get cut out, thats JB weld. I made a small fillet of JB weld in this area to allow the fiberglass to transition easier in this area and not be left with air bubbles and subsequent voids.