DionR

Well-Known Member

Little bit of background. I've asked a couple of questions about my problem, and given this background before, but figured I would bring up to speed anyone that may not seen the other one or two threads.

I got my '74 Duster 360 out of wrecking yard back in '91 or '92 and rebuilt the motor and then drove it as my daily driver up until 2000 or so without a problem. It traded hands at that point in time to a friend (it was his first car) before I got it back about 2 years ago. While my buddy owned it, he pulled the numbers matching shortblock and put it on a stand while he ran a different shortblock. When I got the car back, I put the numbers matching motor back together and dropped it in the car and tried to get it running. From the first time it ran again, it has made a horrible rattling noise, all top end, like none of the lifters would pump up. The motor was virtually unchanged from the way I ran it, so the noise was a mystery.

I've pulled the pan to check the windage tray, put all new lifters in (and replaced a couple of pushrods that were bent), worked to get any exhaust leaks fixed, everything I could. Several months ago, the buddy of mine that owned it last came over and we spend the day trying to diagnose it. We found that if we pulled the fuel pump the noise would get much better, so off came the cover. The only thing we could find under there was that the cam retainer plate was slightly deformed and there was a pretty good internal oil leak at the oil gallery on the drivers side. Figured it was bleeding pressure from the lifters and keeping them from pumping up, so I pounded some plugs into the holes (being careful not to block the intersecting oil passages) and put it back together. The noise was worse, if anything. I was done, and figured it was time to pull the motor and tear it apart.

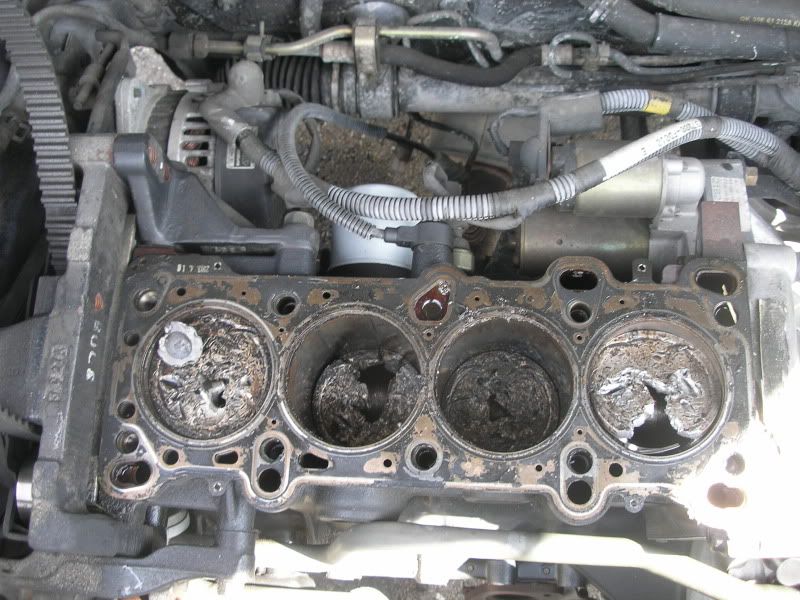

So, last weekend I got the motor out and pulled the heads. This is what I found...

All eight pistons are like that. When I put the motor together, the pistons didn't have valve reliefs. :angry7:

We checked the lifter rise when the piston was at top dead center and found it was .16" off the base circle, over half the lift of the cam (Isky Mega 270). It appears that the new double roller timing chain I installed before I put the motor in the car advanced my cam about 40 degrees (IVO event should be 27 BTDC, but it would take about 67 degrees BTDC to get the .160 lift at the cam). Now my U heads are only cores and all eight 2.02 valves will need to be replaced, lifters are collapsed on the intakes, and I probably have some more bent pushrods. I think the pistons are ok, although I am baffled at how the valves could "cut" reliefs into the piston tops (there doesn't appear to be any metal pushed anywhere and the bottom of the pistons doesn't show any signs of cracks or anything). I never really drove the car, went around the block a couple of times hoping to pump the lifters up, but mostly just idling, and one period of 2000+ rpm when I fired it up with the new lifters.

Moral of the story, degree your cam, regardless of where the timing gear came from, what cam is in the car, or anything else. I assumed the sprocket was machined correctly and didn't check and it cost me two years of driving my car and a considerable chunk of cash. :disgust:

I got my '74 Duster 360 out of wrecking yard back in '91 or '92 and rebuilt the motor and then drove it as my daily driver up until 2000 or so without a problem. It traded hands at that point in time to a friend (it was his first car) before I got it back about 2 years ago. While my buddy owned it, he pulled the numbers matching shortblock and put it on a stand while he ran a different shortblock. When I got the car back, I put the numbers matching motor back together and dropped it in the car and tried to get it running. From the first time it ran again, it has made a horrible rattling noise, all top end, like none of the lifters would pump up. The motor was virtually unchanged from the way I ran it, so the noise was a mystery.

I've pulled the pan to check the windage tray, put all new lifters in (and replaced a couple of pushrods that were bent), worked to get any exhaust leaks fixed, everything I could. Several months ago, the buddy of mine that owned it last came over and we spend the day trying to diagnose it. We found that if we pulled the fuel pump the noise would get much better, so off came the cover. The only thing we could find under there was that the cam retainer plate was slightly deformed and there was a pretty good internal oil leak at the oil gallery on the drivers side. Figured it was bleeding pressure from the lifters and keeping them from pumping up, so I pounded some plugs into the holes (being careful not to block the intersecting oil passages) and put it back together. The noise was worse, if anything. I was done, and figured it was time to pull the motor and tear it apart.

So, last weekend I got the motor out and pulled the heads. This is what I found...

All eight pistons are like that. When I put the motor together, the pistons didn't have valve reliefs. :angry7:

We checked the lifter rise when the piston was at top dead center and found it was .16" off the base circle, over half the lift of the cam (Isky Mega 270). It appears that the new double roller timing chain I installed before I put the motor in the car advanced my cam about 40 degrees (IVO event should be 27 BTDC, but it would take about 67 degrees BTDC to get the .160 lift at the cam). Now my U heads are only cores and all eight 2.02 valves will need to be replaced, lifters are collapsed on the intakes, and I probably have some more bent pushrods. I think the pistons are ok, although I am baffled at how the valves could "cut" reliefs into the piston tops (there doesn't appear to be any metal pushed anywhere and the bottom of the pistons doesn't show any signs of cracks or anything). I never really drove the car, went around the block a couple of times hoping to pump the lifters up, but mostly just idling, and one period of 2000+ rpm when I fired it up with the new lifters.

Moral of the story, degree your cam, regardless of where the timing gear came from, what cam is in the car, or anything else. I assumed the sprocket was machined correctly and didn't check and it cost me two years of driving my car and a considerable chunk of cash. :disgust: