Krooser

Building Chinese Free Engines since 1959...

Already having trouble...

I guess I am having trouble figuring this post out. I have a HF drill press that has worked flawlessly for about 10 years. Are you saying you had a problem with a new HF drill press? They will make it right.

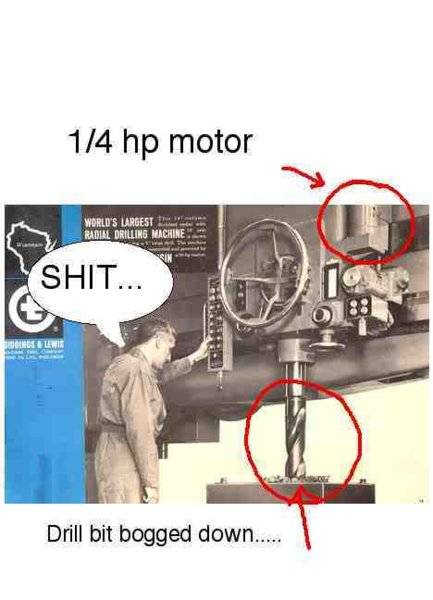

Now that's FUNNY!!!!!Already having trouble...View attachment 1715329669

Uh, sure. I knew that. LOLThink its a joke , guy !

On a serious not many drill presses are geared WAAAAYYYY to high speed for serious metalwork drilling. I got one 'eck of a deal years back on a used Jet drill/ Mill. Now THAT thing will DRILL HOLES!!!

And then there's this arm-breaking, wrist-twistin, head-knockin thang.......

View attachment 1715330285

When I was in the Navy we had a B&D 3/4" drill. Hell you could'a had 10 men, they could not have hung onto that thing. It was in one of those "made for it" drill presses

On a serious note many drill presses are geared WAAAAYYYY too high speed for serious metalwork drilling. I got one 'eck of a deal years back on a used Jet drill/ Mill. Now THAT thing will DRILL HOLES!!!

And then there's this arm-breaking, wrist-twistin, head-knockin thang.......

View attachment 1715330285

When I was in the Navy we had a B&D 3/4" drill. Hell you could'a had 10 men, they could not have hung onto that thing. It was in one of those "made for it" drill presses

wait what?I actually still have a 50's vintage Rockwell drill press with a two speed gearbox. Haven't used it in years but in looking at getting a VFD so I can run it with the 5hp 3 phase motor.

Heavy duty...wait what?

a 5hp 3ph? Carrumba.

On a serious note many drill presses are geared WAAAAYYYY too high speed for serious metalwork drilling. I got one 'eck of a deal years back on a used Jet drill/ Mill. Now THAT thing will DRILL HOLES!!!

And then there's this arm-breaking, wrist-twistin, head-knockin thang.......

View attachment 1715330285

When I was in the Navy we had a B&D 3/4" drill. Hell you could'a had 10 men, they could not have hung onto that thing. It was in one of those "made for it" drill presses

I actually still have a 50's vintage Rockwell drill press with a two speed gearbox. Haven't used it in years but in looking at getting a VFD so I can run it with the 5hp 3 phase motor.

What town?I was at an auction a few miles from my home today and really scored some deals

$80.00 to $120.00 for a VFD that handles the HP.Just get another 5-7hp 3 phase motor and make a RPC, rotary phase converter. They can either be easy and crude or a little harder and more sophisticated. Great option if you can get the motor cheap. I have two, and while I was waiting on parts to make them auto-start, I just used a rope on the shaft to start them. Ping me if you are interested. Lots of DIY designs out there. Reason I suggest RPC is that 220V single-phase input VFDs that can handle 5hp are generally not inexpensive.

I have one of those. My father in law gave me. Used it once to try out. Is know in the bottom of the “gifts I can’t give back Box”On a serious note many drill presses are geared WAAAAYYYY too high speed for serious metalwork drilling. I got one 'eck of a deal years back on a used Jet drill/ Mill. Now THAT thing will DRILL HOLES!!!

And then there's this arm-breaking, wrist-twistin, head-knockin thang.......

View attachment 1715330285

When I was in the Navy we had a B&D 3/4" drill. Hell you could'a had 10 men, they could not have hung onto that thing. It was in one of those "made for it" drill presses

I still have one of those. Can you believe the switch has a lock button? Not mine anymore. That was a crazy moment. Im a southpaw, every drill i own that has a lock is ground off flush.On a serious note many drill presses are geared WAAAAYYYY too high speed for serious metalwork drilling. I got one 'eck of a deal years back on a used Jet drill/ Mill. Now THAT thing will DRILL HOLES!!!

And then there's this arm-breaking, wrist-twistin, head-knockin thang.......

View attachment 1715330285

When I was in the Navy we had a B&D 3/4" drill. Hell you could'a had 10 men, they could not have hung onto that thing. It was in one of those "made for it" drill presses

Nice score.I lucked out, I got this one from work because it did not have the appropriate safety guards so we had to get rid of it, it was free.

View attachment 1715347053