Since I posted the HDK "no camber change" photos on this site

there have been numerous queries regarding bump steer readings

on the HDK.

This week, I fitted a new power steering rack equipped HDK into

a mock-up rig to take some measurements.

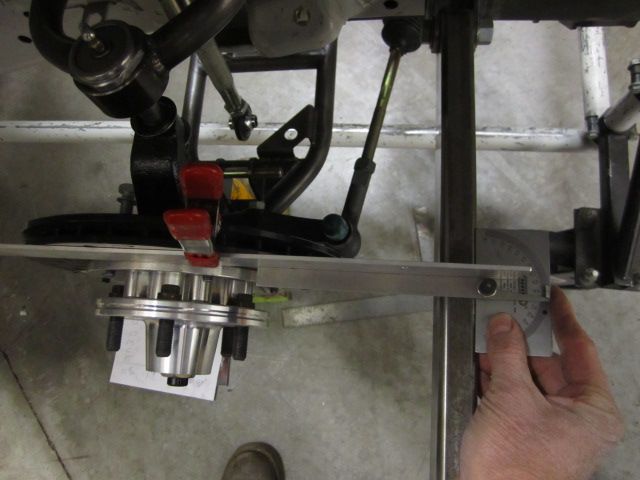

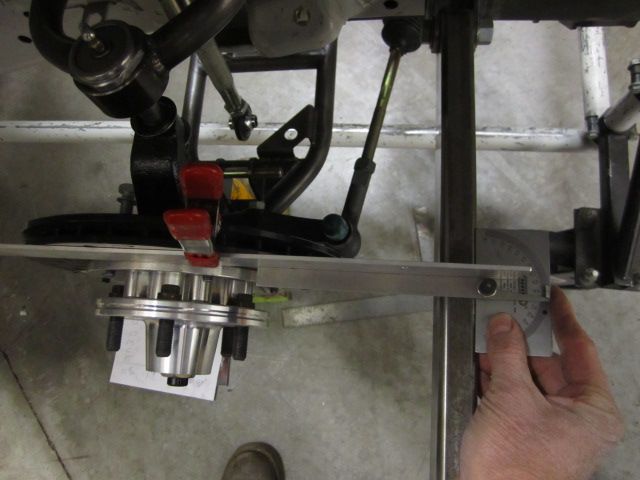

I bolted an adjustable reference arm to the RF unit body rail and

clamped a straight edge to the surface of the brake rotor. Then

with the suspension at different compression heights, I used an

angle guage to measure the tow change (bump steer) at all points

throughout the suspension travel.

The result? Virtually no toe change at any point in the suspension travel arc

of from 10" compressed to 15.5" fully extended (5.5" at the shock which

equates to 6-7/8" at the tip of the spindle).

there have been numerous queries regarding bump steer readings

on the HDK.

This week, I fitted a new power steering rack equipped HDK into

a mock-up rig to take some measurements.

I bolted an adjustable reference arm to the RF unit body rail and

clamped a straight edge to the surface of the brake rotor. Then

with the suspension at different compression heights, I used an

angle guage to measure the tow change (bump steer) at all points

throughout the suspension travel.

The result? Virtually no toe change at any point in the suspension travel arc

of from 10" compressed to 15.5" fully extended (5.5" at the shock which

equates to 6-7/8" at the tip of the spindle).