j par

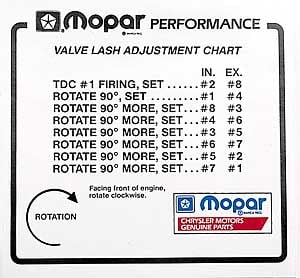

Well-hung Member

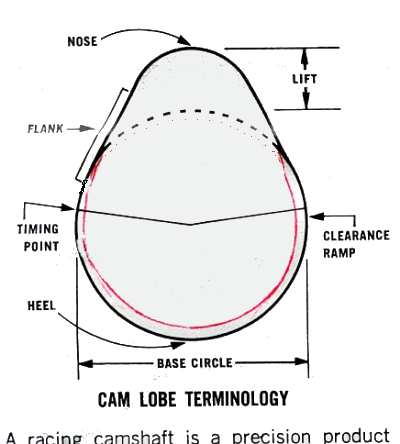

I just got the locking adjusters for the 273 rocker arms and filed the tops flat for the locking nut as per rusty rat rod, thank you.I need help understanding either what my machine shop wrote down as the procedure and/or why I wouldn't just adjust them under base circle like at the time of the power stroke? I'll shoot a picture of the piece of paper that my machine shop with the procedure on and see if it makes sense. I put the picture on a different thread that had already kind of died out and I need help with this today as I'm going to start addressing these so I can put the motor in. Mind you when I posted it last time it came up sideways so you may have to look at your computer a little sideways or have the ability to turn it caddywhompus upright. Thank you for any help, jason .View attachment 20150227_205943.jpg

View attachment 20150227_210007.jpg

View attachment 20150226_222415.jpg

View attachment 20150227_210007.jpg

View attachment 20150226_222415.jpg