Whyjay

Member

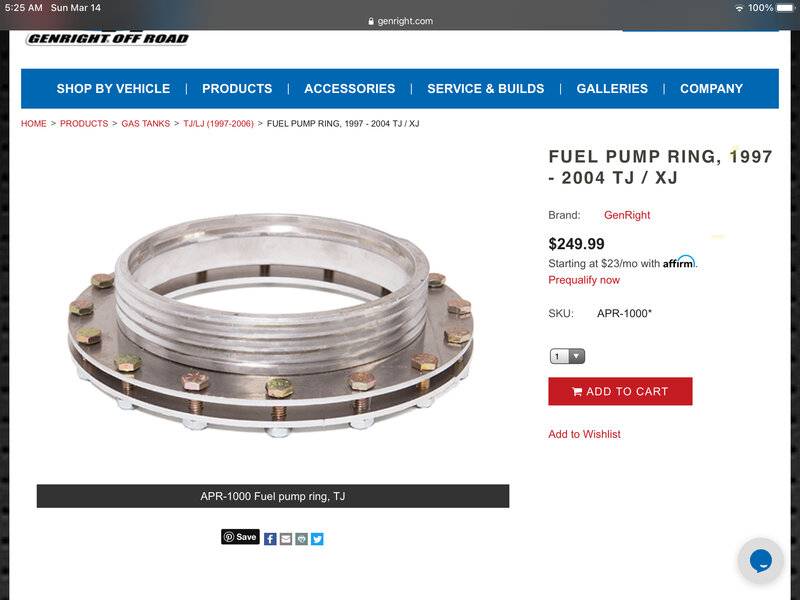

An option for the fuel pump is one of these adapters.

I like this idea and am going to give it a try. Are there any clearance issues between the pump and the trunk floor?Yup easy button for sure. I bought a new Abody tank and mounted the stock RAM pump.

View attachment 1715704866

Yes. It required some creative hammering on my car. 72 dart. Your results may vary.I like this idea and am going to give it a try. Are there any clearance issues between the pump and the trunk floor?

Just curious, approx how much pounding? Approx an inch?Yes. It required some creative hammering on my car. 72 dart. Your results may vary.

Yea maybe about that on a stock trunk pan. Mine was hacked up when I got it so I don’t have a great reference really. But the FPR sits about 1-1/2” off the top of the tank if that helps.Just curious, approx how much pounding? Approx an inch?

Thanks for the info. Not trying to hijack but maybe would give Truckie ideas too...What did you do for flange? Tabs or cut out from a stock tank? Did you make a custom gasket, cork or rubber? How did it hold up re leaks when tank full? Thanks in advance.Yea maybe about that on a stock trunk pan. Mine was hacked up when I got it so I don’t have a great reference really. But the FPR sits about 1-1/2” off the top of the tank if that helps.

I wish I took more pictures, sorry I didn’t. I cut a flange a little larger than the hole, same size as the diameter of the mounting flange on the fuel pump. Drilled holes (3) in the flange, and the tank, pushed the studs up through the flange and the tank and welded them in place. The tabs on the top are held in place with nuts and sandwich the tank between the flange and the pump. The gasket I cut from thin rubber gasket material I got from McMaster Carr. Can’t remember the thickness I used. Zero problems with leaks ever. Hope that helps.Thanks for the info. Not trying to hijack but maybe would give Truckie ideas too...What did you do for flange? Tabs or cut out from a stock tank? Did you make a custom gasket, cork or rubber? How did it hold up re leaks when tank full? Thanks in advance.

Can you describe what you had to do to the telescopic part to make it work?More pics is going to be hard because I don’t have any. And the tank is sitting under a workbench at my shop covered in dust. But I bought a new tank, cut a big hole in the top, welded studs (3) to the top, and modified the spring loaded telescopic base for the depth I needed. I used a new tank because I knew I was welding to it and cutting on it and I wanted one that never had gas in it. Plus my tank was original to the car and had rust in it. If you weld to an old one, fill it with water and-or purge it with an inert gas. I used this setup with zero problems for a while stock and now it’s completely different for the turbo setup, needed a lot more pump.

I could tell you but then I’d have to kill you. It’s top secret.Can you describe what you had to do to the telescopic part to make it work?

I greatly appreciate it.I could tell you but then I’d have to kill you. It’s top secret.

Really I don’t remember I did it so long ago. But just for you I’ll pull the fuel tank out from under my bench on Monday and take the pump out of it and snap some pics.

Thanks that definitely helps. I pulled the pump out of the donor so I will modify it first so if I screw up I’m not out any money.Ok @Truckie sorry it took a few days. Here are some pics of my modified sending unit. I did this in about 2012 so i really didn’t remember much about doing it and this has jogged my memory. It’s pretty clear that I cut and shortened the top portion of the outer “sleeve” to the depth of the stock tank and the “inner” sleeve is just a slight press fit in to it. The bottom of the sending unit lightly bottoms on the tank floor (that’s how it’s designed to sit) and once bolted in at the top has no way of coming apart. Hopefully that will make sense once you see the pictures. I bought this new from NAPA so I added their inventory pics for reference.

View attachment 1715713061

View attachment 1715713057

View attachment 1715713058

View attachment 1715713059

View attachment 1715713060

I made a flange. I posted above ^ how I did it.Thanks that definitely helps. I pulled the pump out of the donor so I will modify it first so if I screw up I’m not out any money.

Did you make any kind of ring to go inside the tank for the bolts to pass through to make the hole in the tank more rigid?

If you're going stock efi, grab the pedal and it's connected cable from same year donor vehicle. It'll snap right into the throttle body. Drill some new holes for the pedal mount in your floor/wall and run cable to throttle body. If the bend of cable isn't proper you may need shorter or longer cable from different model (van vs truck, etc). I'm going through this now to see if I can get a better loop around the manifold.A little bit different question. What is everyone using for a throttle cable with the stock efi set up?

$350 vs $0 is my reason.Why not just buy the Holley drop in fuel pump assembly. It’s designed for the new hemi swap parts they make. Holley Sniper EFI 12-319 Holley 255 LPH OE Style EFI Fuel Tank Modules

I got my fuel pump modified and the hole in my tank. I made the hike so the original rubber gasket fits in it nicely. I was wondering, the original pump had openings in the side that I’m assuming were to let fuel in to cool the pump. Is is necessary to put a few holes in the side, just below where the two pieces come together?Ok @Truckie sorry it took a few days. Here are some pics of my modified sending unit. I did this in about 2012 so i really didn’t remember much about doing it and this has jogged my memory. It’s pretty clear that I cut and shortened the top portion of the outer “sleeve” to the depth of the stock tank and the “inner” sleeve is just a slight press fit in to it. The bottom of the sending unit lightly bottoms on the tank floor (that’s how it’s designed to sit) and once bolted in at the top has no way of coming apart. Hopefully that will make sense once you see the pictures. I bought this new from NAPA so I added their inventory pics for reference.

View attachment 1715713061

View attachment 1715713057

View attachment 1715713058

View attachment 1715713059

View attachment 1715713060

Necessary? I don’t think so for three reasons, one mine ran flawlessly. Two if you’ll notice the return fuel is fed right down the middle of the sending unit filling it while at anything but full throttle. Idle there is lots of return fuel, WOT there is not so much. Three, it’s submerged in fuel and not a sealed unit so it fills up anyway.I got my fuel pump modified and the hole in my tank. I made the hike so the original rubber gasket fits in it nicely. I was wondering, the original pump had openings in the side that I’m assuming were to let fuel in to cool the pump. Is is necessary to put a few holes in the side, just below where the two pieces come together?

Here’s some pics. First is the modified pump. Second shows (kinda) the stock gasket. Fits pretty snug once pump is all the way in. The others show the flanges I’m working on. The one with slit will have threaded holes that I will run stainless bolts with rubber washers through. It will go inside the tank with a rubber gasket. The other ring will hold the pump down. Trying to decide how many bolts to use. I was thinking about 7, but the more holes the more chance of leaking.Oh and post pics.

Thanks. I think it was you that mentioned before about getting me a picture of how to wire the key to the new wiring. I think you said you had something set up on an engine run stand. Any chance you can tell me what I need to do to fire this thing up?Nice work!