pishta

I know I'm right....

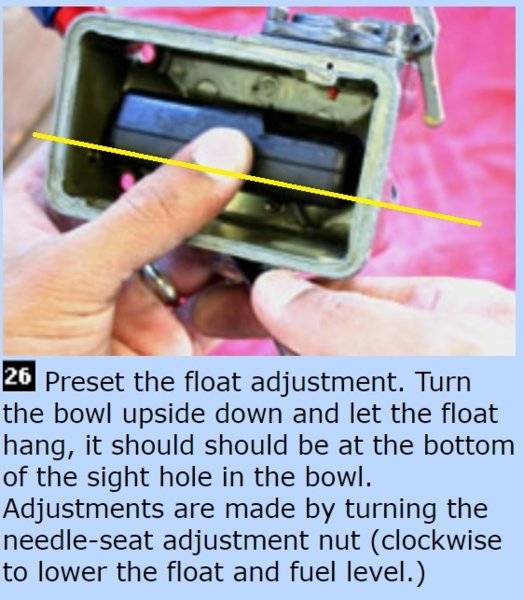

bend the tang on the float. IIRC adjust float 'hang' when you turn the bowl over: put a pencil between the inverted float and the top of the bowl (bottom when its inverted) and adjust so the pencil is the feeler guage. They do it here to some extent. Yellow line is bottom of plug, midpoint on large sight glass (way safer than dribbling plugs on an idling motor!)

Also on an older Holley, you are turning the large floating nut under the screw top that is keyed onto the needle seat, your not turning the needle seat directly. The top large head screw is the gasket sealing mechanism. loosen screw slightly, turn nut and tighten screw: a big mess when your motor is running as your surely going to get fuel at 5-7 psi to squirt out of screw.

Also on an older Holley, you are turning the large floating nut under the screw top that is keyed onto the needle seat, your not turning the needle seat directly. The top large head screw is the gasket sealing mechanism. loosen screw slightly, turn nut and tighten screw: a big mess when your motor is running as your surely going to get fuel at 5-7 psi to squirt out of screw.

Last edited: