I guess I really don't understand the general point.Fair enough Mike. But, I think most would agree on the general point.

I sold my W2 stuff at Carlisle a few years ago. I did OK on it but kinda wish I held on to it because the investment to get back into them is probably close to cost prohibitive now. Live and learn.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Holley Strip Dominator vs. Edelbrock Victor 340

- Thread starter rmchrgr

- Start date

-

rmchrgr

Skate And Destroy

Moving on -

My new-to-me Victor 340 showed up today. As mentioned previously, I had one on my old W2 340 so it's kinda like seeing an old friend again.

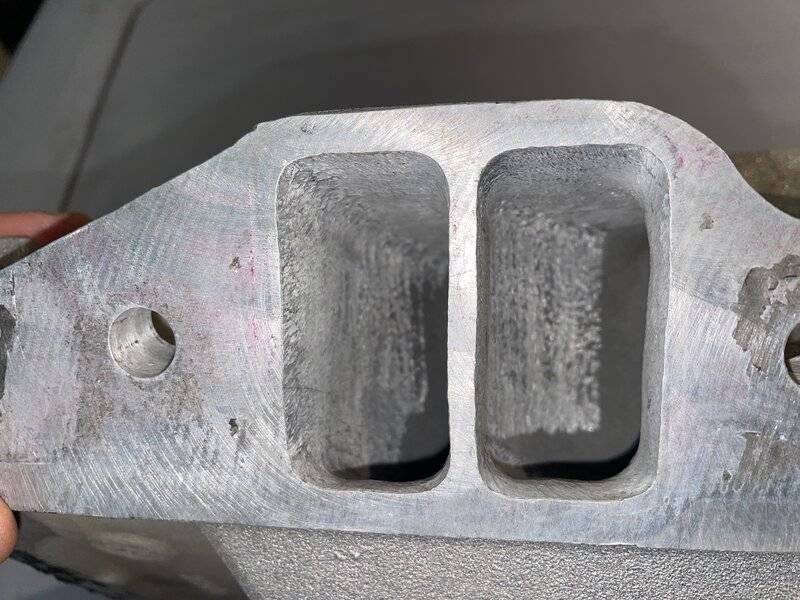

In any event, this one has had some work done to it. I honestly don't know exactly what I'm looking at but it seems consistent from port to port. They left the dividers alone and only sort of "touched up" the plenum under the throttle body opening. Hard to see in the pic but the floor has been blended/smoothed I guess for lack of a better description.

I read up on intake porting and went down a rabbit hole regarding surface finish. If you believe what you read on the interwebs, a "dimpled" or sort of rough finish can prevent fuel drop out and ultimately help make power. Reading through all that it occurred to me the grinding on my Strip Dominator might actually be too smooth. My inclination is to blend this work a little better while trying not to make it super smooth. Not sure how that would work out. This is the finish up close.

Runners.

Similar to my Strip Dominator, I'd say it's been more "gasket matched" than "port matched" though it's hard to tell just looking at it. Will be a bit before this thing is bolted on and checked out for reals but thanks to JustinP I have a good idea how to proceed on that front. Hopefully it's not too far off.

Thoughts? Questions? Comments? 1-800-EAT-....

My new-to-me Victor 340 showed up today. As mentioned previously, I had one on my old W2 340 so it's kinda like seeing an old friend again.

In any event, this one has had some work done to it. I honestly don't know exactly what I'm looking at but it seems consistent from port to port. They left the dividers alone and only sort of "touched up" the plenum under the throttle body opening. Hard to see in the pic but the floor has been blended/smoothed I guess for lack of a better description.

I read up on intake porting and went down a rabbit hole regarding surface finish. If you believe what you read on the interwebs, a "dimpled" or sort of rough finish can prevent fuel drop out and ultimately help make power. Reading through all that it occurred to me the grinding on my Strip Dominator might actually be too smooth. My inclination is to blend this work a little better while trying not to make it super smooth. Not sure how that would work out. This is the finish up close.

Runners.

Similar to my Strip Dominator, I'd say it's been more "gasket matched" than "port matched" though it's hard to tell just looking at it. Will be a bit before this thing is bolted on and checked out for reals but thanks to JustinP I have a good idea how to proceed on that front. Hopefully it's not too far off.

Thoughts? Questions? Comments? 1-800-EAT-....

Keep it up Greg!

B3422w5

Well-Known Member

Moving on -

My new-to-me Victor 340 showed up today. As mentioned previously, I had one on my old W2 340 so it's kinda like seeing an old friend again.

View attachment 1715889740

In any event, this one has had some work done to it. I honestly don't know exactly what I'm looking at but it seems consistent from port to port. They left the dividers alone and only sort of "touched up" the plenum under the throttle body opening. Hard to see in the pic but the floor has been blended/smoothed I guess for lack of a better description.

View attachment 1715889742

I read up on intake porting and went down a rabbit hole regarding surface finish. If you believe what you read on the interwebs, a "dimpled" or sort of rough finish can prevent fuel drop out and ultimately help make power. Reading through all that it occurred to me the grinding on my Strip Dominator might actually be too smooth. My inclination is to blend this work a little better while trying not to make it super smooth. Not sure how that would work out. This is the finish up close.

View attachment 1715889743

Runners.

View attachment 1715889744

View attachment 1715889745

View attachment 1715889746

Similar to my Strip Dominator, I'd say it's been more "gasket matched" than "port matched" though it's hard to tell just looking at it. Will be a bit before this thing is bolted on and checked out for reals but thanks to JustinP I have a good idea how to proceed on that front. Hopefully it's not too far off.

Thoughts? Questions? Comments? 1-800-EAT-....

look at the Victor i just had done. Just made a thread about it couple days ago on here. Guy did very nice work on it

rmchrgr

Skate And Destroy

Keep it up Greg!

I got it like this Rob, I only just took it out of the box tonight. The ad said "quality gasket matched".

look at the Victor i just had done. Just made a thread about it couple days ago on here. Guy did very nice work on it

Wow, that thing seems to have had some work done to it. I'm not doing anything to mine until I bolt it on and see how it lines up though.

After you’ve done some baselining, get yourself a die grinder and some burrs and have at it. Smooth out the bumps and bulges that are in the 3/5 and 4/6 short turn radius’s and outside radius’s of the same runners at a minimum, do a port/gasket match, blend it up into the runners some, work the plenum carb flange to runners as you see fit. Burr finish or roll it with some 40 or 60 grit, whatever. Here’s some eye candy, nothing shown that hasn’t been done by others here or elsewhere, a couple of little details applied as has been mentioned by Vizard, Weingartner and Speier. Can’t wait to run this thing and see the results.

3/1 and 2/4 runners (note 1/2 divider: 1 knife edge/ 2 radius detail per Vizard/Weingartner)

6/8 and 7/5 runners (note 7/5 divider: 7 knife edge/ 5 radius detail per as above)

7/5/3/1 runners

3/1 and 2/4 runners (note 1/2 divider: 1 knife edge/ 2 radius detail per Vizard/Weingartner)

6/8 and 7/5 runners (note 7/5 divider: 7 knife edge/ 5 radius detail per as above)

7/5/3/1 runners

Last edited:

Rat Bastid

Dunamis Metron

After you’ve done some baselining, get yourself a die grinder and some burrs and have at it. Smooth out the bumps and bulges that are in the 3/5 and 4/6 short turn radius’s and outside radius’s of the same runners at a minimum, do a port/gasket match, blend it up into the runners some, work the plenum carb flange to runners as you see fit. Burr finish or roll it with some 40 or 60 grit, whatever. Here’s some eye candy, nothing shown that hasn’t been done by others here or elsewhere, a couple of little details applied as has been mentioned by Vizard, Weingartner and Speier. Can’t wait to run this thing and see the results.

View attachment 1715890735

View attachment 1715890737

View attachment 1715890739

View attachment 1715890740

View attachment 1715890742

View attachment 1715890743

View attachment 1715890746

View attachment 1715890747

View attachment 1715890748

View attachment 1715890749

VERY NICE WORK!!!!!

OldmanRick

Well-Known Member

Man that's purrdy.

Swinger 340

Well-Known Member

Nice Job with the runners. I made a comment a few months ago on just that, tumbling the fuel with the ruffing of runners and was beat up by someone. Thanks for reinforcing my thoughts. Note: This is a better job than I did.

It certainly looks pretty if I do say so myselfNice Job with the runners. I made a comment a few months ago on just that, tumbling the fuel with the ruffing of runners and was beat up by someone. Thanks for reinforcing my thoughts. Note: This is a better job than I did.

rmchrgr

Skate And Destroy

After you’ve done some baselining, get yourself a die grinder and some burrs and have at it.

Wow, looks good. That's a lot of work.

I do need to get some longer shank burrs for the hard-to-reach areas. Got a box of sanding rolls already.

-

Similar threads

- Locked

- Replies

- 3

- Views

- 483

- Replies

- 0

- Views

- 214

- Replies

- 3

- Views

- 433