You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hughesy's 1973 Valiant Charger - New Hemi 5.7 swap

- Thread starter Boony405hp

- Start date

-

Boony405hp

Well-Known Member

Boony405hp

Well-Known Member

The painless kit that needs to be installed, so many wires.

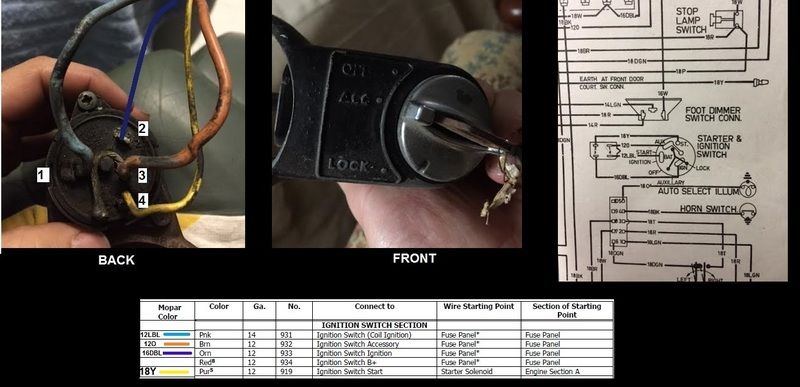

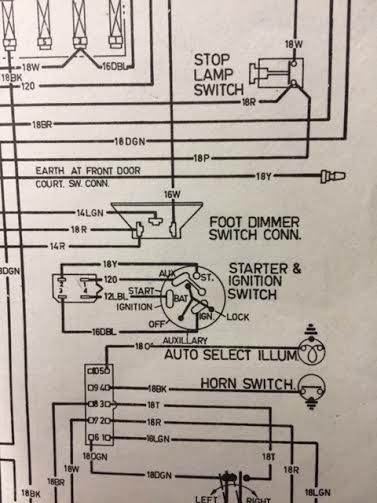

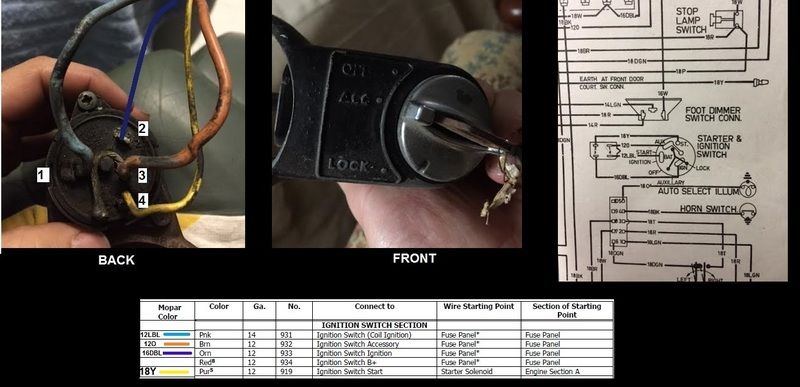

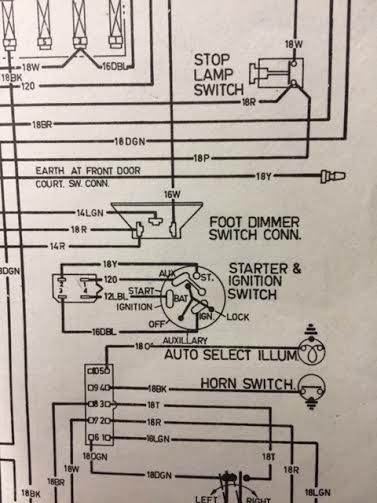

I am also running a hotwireauto harness, so I need to work out the marriage of what I won’t use from the painless. The hotwireauto states you must use there harness to start the vehicle. It appears to have a starter relay built in which I assume makes the old style starter relay obsolete. I am still working out the wiring to this with the whole ‘start button for firing the engine’ and ‘bridging out ign1 and ign2’ the Australian ignition barrel doesn’t have anything labelled ign1, ign2 but I’d presume it would have contacts that do the same job.

The pile of wires that I need to route, the hole location says to place behind the passenger head just below the fuel rail. I couldn’t quite get that location but I got fairly close, most wires reached easily. I think if you are going to do this the best way would be to connect and lay the harness over the engine while it is out of the car. You could get a good idea where you need to drill the hole in your firewall.

VE Commodore firewall grommet

Factory Computer (from 05 ram that has been flashed) installed

Painless fuse panel mounted on drivers side

Mounted and installed the drive by wire accelerator pedal, not a straight bolt on job, I slightly sliced and lifted up and boxed the edges of the floorpan to allow me to mount it flush. I am going to have the pedals modified to use the modern factory sports pads (Aluminium with little rubber pads)

I am also running a hotwireauto harness, so I need to work out the marriage of what I won’t use from the painless. The hotwireauto states you must use there harness to start the vehicle. It appears to have a starter relay built in which I assume makes the old style starter relay obsolete. I am still working out the wiring to this with the whole ‘start button for firing the engine’ and ‘bridging out ign1 and ign2’ the Australian ignition barrel doesn’t have anything labelled ign1, ign2 but I’d presume it would have contacts that do the same job.

The pile of wires that I need to route, the hole location says to place behind the passenger head just below the fuel rail. I couldn’t quite get that location but I got fairly close, most wires reached easily. I think if you are going to do this the best way would be to connect and lay the harness over the engine while it is out of the car. You could get a good idea where you need to drill the hole in your firewall.

VE Commodore firewall grommet

Factory Computer (from 05 ram that has been flashed) installed

Painless fuse panel mounted on drivers side

Mounted and installed the drive by wire accelerator pedal, not a straight bolt on job, I slightly sliced and lifted up and boxed the edges of the floorpan to allow me to mount it flush. I am going to have the pedals modified to use the modern factory sports pads (Aluminium with little rubber pads)

Modz

New Member

Glad to see so much progress Hughsey well done! Impressed with the brake booster setup, I was heading the under dash way as I couldn't fit the VE setup - didn't think of notching the guard!

Unfortunately I parted out my 75 VJ Charger and 727 / 5.7 Hemi build since you started, yours was always the benchmark for my build. NZ changed their welding rules so you have to have a welding ticket to do any resto work on a car now, has killed a lot of the scene here.

On the upside, I have a billet oil dipstick for a 5.7L hemi brand new in plastic if you want it. Just PM me if you want it (cheap), its been sitting in my garage for 2 years now.

Unfortunately I parted out my 75 VJ Charger and 727 / 5.7 Hemi build since you started, yours was always the benchmark for my build. NZ changed their welding rules so you have to have a welding ticket to do any resto work on a car now, has killed a lot of the scene here.

On the upside, I have a billet oil dipstick for a 5.7L hemi brand new in plastic if you want it. Just PM me if you want it (cheap), its been sitting in my garage for 2 years now.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,327

NZ changed their welding rules so you have to have a welding ticket to do any resto work on a car now, has killed a lot of the scene here.

Can't blame them, after some of the horrendous welding I've seen..Then again, they could allow it to be inspected, but as usual people will just lie about what they have done to avoid that. Don't blame the Government, blame the back yard hacks. Not hard to do a welding coarse at Tech, or college. If you cant afford to pay to do a coarse, then I guess you can't afford to buy a decent welder or build a car.

-

Similar threads

- Replies

- 38

- Views

- 1K

- Replies

- 7

- Views

- 294