You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Im convinced there is so much bullshit with these companies Right stuff is a joke

- Thread starter J.B.

- Start date

-

That's really impressive... how does the rear axle move up and down, or the front wheels steer without brake hoses???There are no rubber lines on the car.

CONGRATULATIONS!!! Looks like you are ready to roll... I mean stop... you know what I mean!Relocated from rear floating axle setup to front. Made a mini line to connect the rear proportioning valve and bring it all together finally!

Braided-steel/synthetic cores.That's really impressive... how does the rear axle move up and down, or the front wheels steer without brake hoses???

CONGRATULATIONS!!! Looks like you are ready to roll... I mean stop... you know what I mean!

BillGrissom

Well-Known Member

Looks good. Since yours was a drum-drum car, the factory block is just a "distribution block" with a pressure imbalance warning switch (to dash lamp, in parallel w/ hand brake switch). For anyone with a factory disk-drum car, you wouldn't want to keep that different "combination block" since it has an internal proportioning valve which lowers pressure to the rear drums. The added adjustable proportioning valve is mandatory if adding front disks and keeping rear drums, to reduce drum pressure to avoid locking up the rears first. In your case, it wouldn't be needed if front and rear disk brakes are equally matched, so might need it set to just slightly reduce rear pressure. Ideally, test the brakes in a wet parking lot, with a ground observer. Adjust until the fronts skid just before the rears.

My trans cooling lines from inline did that, very easy to unbend.I did new brake lines and when they were shipped and bent there was a piece of tape to show where to unbend it. I don't remember whether it was in line or the right stuff.

Chris1974

Active Member

J B I know this doesn't help you, but it may well help another a body guy. I bought a kit from wilwood to do just the front disc brake conversion on my 74 duster and it turned into a nightmare. Like a dumb *** I didn't get the balls to start it for over a year and when I did I found out that wilwoods stuff would not fit on my spindles so I called them and the tech guy said basically if our stuff doesent fit your car your car is the problem and by the way since you have already had it for a year we aint taking it back. I was totally screwed and was considering scrapping the conversion kit and putting my drums back on but this kit is a thousand bucks. I was telling the story to my body man and he says and we confirmed this that 74 was the last year for the solid bumpers and 75 had the 5 mph bumpers and so they were using whatever parts they had because everything was changing and as it turns out this car was considered a late 73 early 74 so I called Mike from AMS Obsolete who I bought my bumpers from and asked him if he knew anything about that they have a huge yard and tons old dealership parts including NOS and he also confirmed they were using 73 parts on 74 model years and he said you have 73 spindles not 74 so fortunately for me he had 73 spindles and took them off a car and sent them to me. The rest of the install went pretty smoothly I have non power brakes and a stock master I did make new lines as required which took some trial and error but like others have said here take a step back and regroup and you will make it happen

If this stuff was easy everyone would be doing it..........

If this stuff was easy everyone would be doing it..........

MILO

Well-Known Member

Usually things made overseas have very poor instructions I guess its just the way nowadays

ajarofclay

Well-Known Member

Damn, very timely but you guys are scaring the **** outta me. My story started with trying a "Bolt on" conversion from SSBC because it seemed like the easiest way to convert to 4.5 bolt pattern. Paid, Long back order, issue with brake lines, eventual no clearance an rotors ground against brackets. 8 months later of being shmoozed around... returned. Now in the middle of a Tom's classic setup and the calipers reliefs are milled wrong for the brake pads. Just discovered and they seem to be interested in rectifying it? We'll see, update later. I've read many opinions on here in other threads regarding valves and masters and am hoping to change from the distribution block the a factory style proportioning valve and a factory disc/drum master. I don't want an adjustable if I can avoid it. Also, I've got manual brakes and don't want to change to power. On top of all that  My 8.75 rear is a (correctly) narrowed B body with 11" brakes and the fronts are the larger 11.75 upgrades. This is going to be SO much fun.

My 8.75 rear is a (correctly) narrowed B body with 11" brakes and the fronts are the larger 11.75 upgrades. This is going to be SO much fun.

Dragonsteel

Well-Known Member

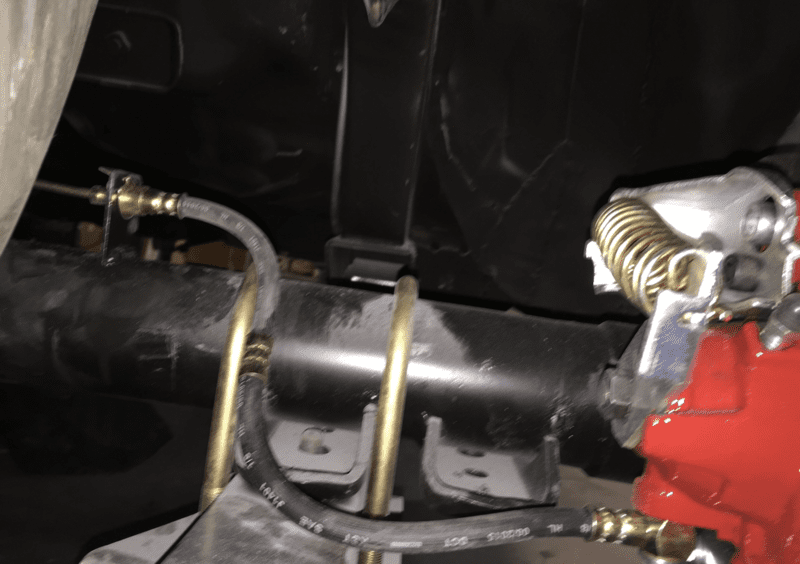

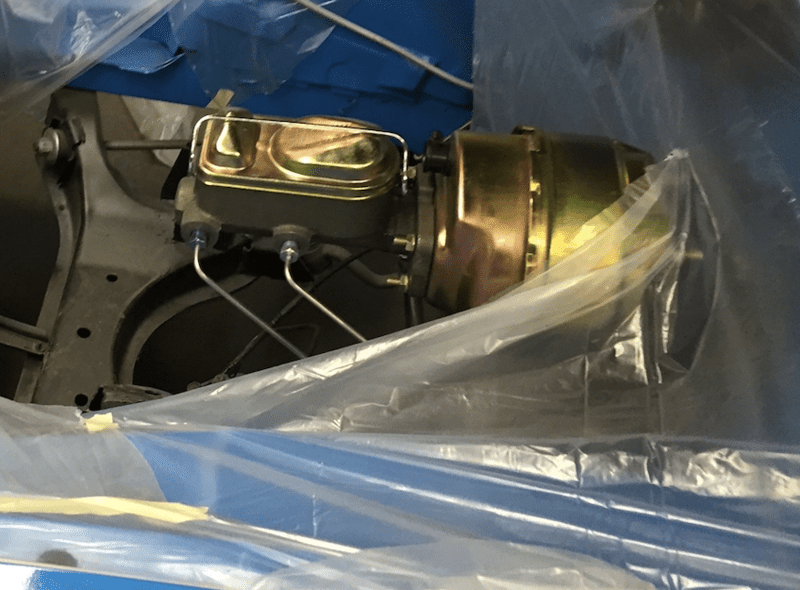

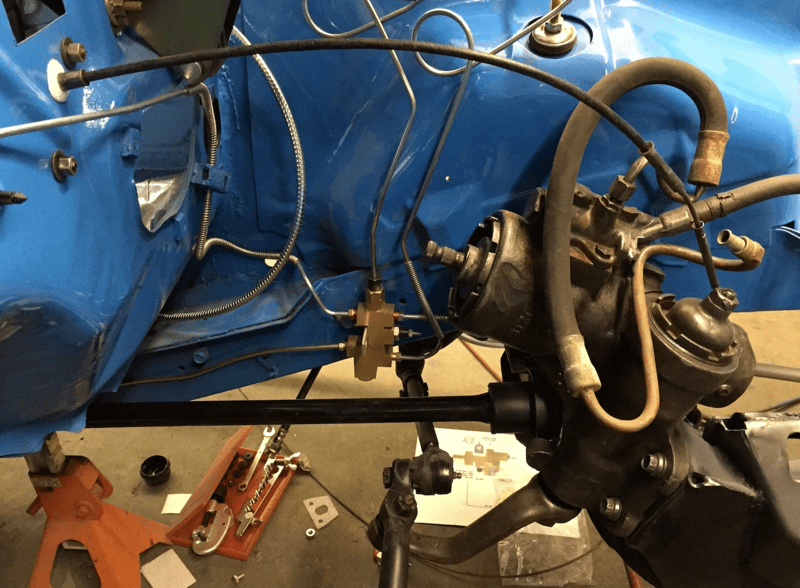

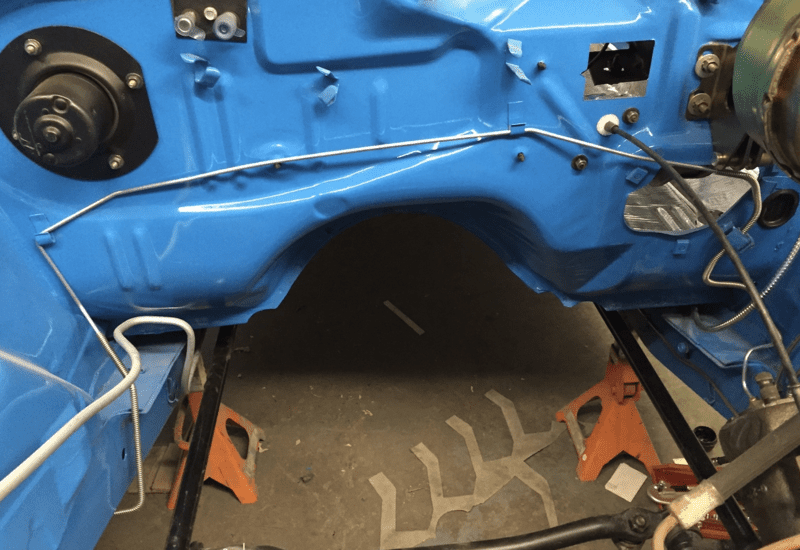

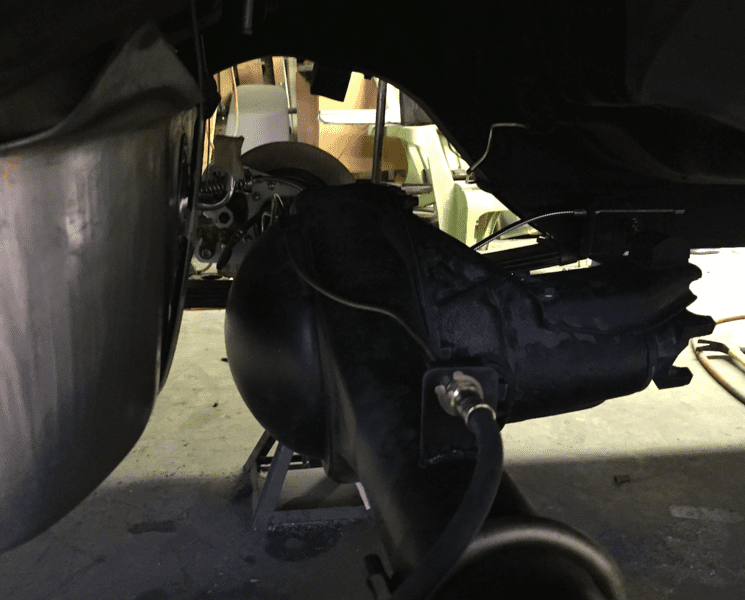

A few photos for what it's worth in helping you solve your problems. I have the same 4 wheel disc brake kit on my Dart, but did not purchase brake lines from them. I made my own line from the proportioning valve to the rear of the car (I chose not to use their proportioning valve, bought a factory style disc brake p-valve) and have factory style rubber lines on the rear. I either made or bought the tabs welded on the rear axle housing to secure the lines. Engine compartment lines were from in-line tube. I did ditch the master cylinder for an aluminum one from Doctor Diff as I could not get it to stop leaking around the cap. E- brake lines are a pain as they sent equal length lines that were not useable as the line runs down the drivers side, so I had to source the longer line and had to split the mounting tab and on the body and relocate it to get equal line tension. A lot of work and trial and error was needed to get it right, but the cars brakes are just right not over powered and not under powered.

LOL. We are all members of this club!

Thank you for the insitindid step back and reevaluate everythingJ B I know this doesn't help you, but it may well help another a body guy. I bought a kit from wilwood to do just the front disc brake conversion on my 74 duster and it turned into a nightmare. Like a dumb *** I didn't get the balls to start it for over a year and when I did I found out that wilwoods stuff would not fit on my spindles so I called them and the tech guy said basically if our stuff doesent fit your car your car is the problem and by the way since you have already had it for a year we aint taking it back. I was totally screwed and was considering scrapping the conversion kit and putting my drums back on but this kit is a thousand bucks. I was telling the story to my body man and he says and we confirmed this that 74 was the last year for the solid bumpers and 75 had the 5 mph bumpers and so they were using whatever parts they had because everything was changing and as it turns out this car was considered a late 73 early 74 so I called Mike from AMS Obsolete who I bought my bumpers from and asked him if he knew anything about that they have a huge yard and tons old dealership parts including NOS and he also confirmed they were using 73 parts on 74 model years and he said you have 73 spindles not 74 so fortunately for me he had 73 spindles and took them off a car and sent them to me. The rest of the install went pretty smoothly I have non power brakes and a stock master I did make new lines as required which took some trial and error but like others have said here take a step back and regroup and you will make it happen

If this stuff was easy everyone would be doing it..........

nice thanks for all that good to know its almost there like yours i dont have a welder so i have these securing straps for the axle hose securing bracketsA few photos for what it's worth in helping you solve your problems. I have the same 4 wheel disc brake kit on my Dart, but did not purchase brake lines from them. I made my own line from the proportioning valve to the rear of the car (I chose not to use their proportioning valve, bought a factory style disc brake p-valve) and have factory style rubber lines on the rear. I either made or bought the tabs welded on the rear axle housing to secure the lines. Engine compartment lines were from in-line tube. I did ditch the master cylinder for an aluminum one from Doctor Diff as I could not get it to stop leaking around the cap. E- brake lines are a pain as they sent equal length lines that were not useable as the line runs down the drivers side, so I had to source the longer line and had to split the mounting tab and on the body and relocate it to get equal line tension. A lot of work and trial and error was needed to get it right, but the cars brakes are just right not over powered and not under powered.

View attachment 1716165233

View attachment 1716165234

View attachment 1716165235

View attachment 1716165236

View attachment 1716165237

View attachment 1716165238

69b7bbgts

Well-Known Member

My customer bought that same kit. What I had to do in the rear is well actually. They give you tabs to well down to the rear end to secure the brake hose brake line junction and I noticed somebody mentioned the master cylinder being wrong. That is correct. I have the same master cylinder and when you hit the brakes you initially get that power brake feel but then also and it comes to a dead stop and I bet you it's because it has a drum rear brake master cylinder. Nice catch I will have to replace that

I can easily explain why this happens with overseas stuff as I am in the business of manufacturing aftermarket automotive parts overseas and selling them in the USA, and also why you call these manufacturers and no one knows anything. The issue is simple, most of this stuff is just copied off a USA manufacturer. You find a product that has huge profit margins and good sales, you buy said product from the original manufacturer, you send it to your overseas broker who finds a manufacturer who can copy it, or who already makes some or all of the parts you need and pieces it for you. You never really end up with exactly the same thing, but something very similar that will work. Quality is usually decent, and it will fit and work, but there will be no instructions, as you do not want to copy the original instructions (and you really can't as it is not 100% the same), and no one there has ever installed this thing to make your own detailed instructions. This gets sold at a good discount from the original kit made in the USA. You can't call these companies and ask them how to install this kit as they have no clue, as they did not design the kit and they have never installed one, they just copied the kit off some other manufacturer. Eventually these companies get to the point where they can help you a bit with the install, as after years of dealing with customers having problems they learn from these customers how to install the kits...Usually things made overseas have very poor instructions I guess its just the way nowadays

That makes alot of sense so then the question is who is the lion share company that makes the original kit with instructions lolI can easily explain why this happens with overseas stuff as I am in the business of manufacturing aftermarket automotive parts overseas and selling them in the USA, and also why you call these manufacturers and no one knows anything. The issue is simple, most of this stuff is just copied off a USA manufacturer. You find a product that has huge profit margins and good sales, you buy said product from the original manufacturer, you send it to your overseas broker who finds a manufacturer who can copy it, or who already makes some or all of the parts you need and pieces it for you. You never really end up with exactly the same thing, but something very similar that will work. Quality is usually decent, and it will fit and work, but there will be no instructions, as you do not want to copy the original instructions (and you really can't as it is not 100% the same), and no one there has ever installed this thing to make your own detailed instructions. This gets sold at a good discount from the original kit made in the USA. You can't call these companies and ask them how to install this kit as they have no clue, as they did not design the kit and they have never installed one, they just copied the kit off some other manufacturer. Eventually these companies get to the point where they can help you a bit with the install, as after years of dealing with customers having problems they learn from these customers how to install the kits...

That makes alot of sense so then the question is who is the lion share company that makes the original kit with instructions lol

On this particular kit I would not know, but you can look at a million examples of this like anything Speedmaster sells, the copies of Holley carburetors and fuel pumps, copies of Carter mechanical and electric fuel pumps, copies of the Edelbrock heads and intakes, the new copies of the Edelbrock carburetors, Copies of HEI distributors especially the ones that fit engines other than a Chevy, Chinese aluminum radiators, Chinese AN fittings and hoses, Chinese forged crank and rods, Chinese high torque mini-starters, Chinese Turbochargers and wastegates, Chinese Flowmaster mufflers, Chinese Borla mufflers, Chinese billet throttle bodies, I could go on forever. Most of the stuff that is sold under the Jegs or Summit brand. All of this stuff was USA produced product that at some point was bought from a USA seller, it was shipped overseas, and copied.That makes alot of sense so then the question is who is the lion share company that makes the original kit with instructions lol

ALL our cars are full of this stuff, that is why everyone complains about the quality of aftermarket automotive products today. Almost every single part that used to be made in the USA was at some point shipped to China and copied, it then came back to the USA and killed the USA made product because of the lower price. Some manufacturers here shipped their factories to China and then screwed themselves even more as they then taught the Chinese how the stuff was really made and now even the machinery to make the parts was copied. Originally this started in Taiwan, and then moved to China as China was cheaper. Taiwan product was much better quality that the China stuff. The Taiwan product was usually as good or reasonably close to the quality of the USA product but for a lesser price. People started buying the Taiwan stuff, which was decent, and that is where the change started happening. The Taiwan product started putting the nails on the coffin of the USA made product and then the China stuff came in at an even lower price and killed the USA manufacturers. By the time China product started taking over people here were already used to buying the Taiwan stuff that was much better quality and most could not tell the difference. Eventually the China product supplanted the Taiwan product.

Basically the China R&D department is called Rip-Off and Duplicate...

Dartswinger70

Well-Known Member

I attached a Auto meter tach to my steering column with a hose clamp...

69b7bbgts

Well-Known Member

So I double checked the master cylinder it was 15/16 like it's supposed to be for disc disc. The next thing they had me check was free play in the pedal. I already had that. So the only thing that I can think of is possibly brake pads/ rotors need to break into each other. Has anybody else experience that?

-