Peini

Well-Known Member

Hi guys,

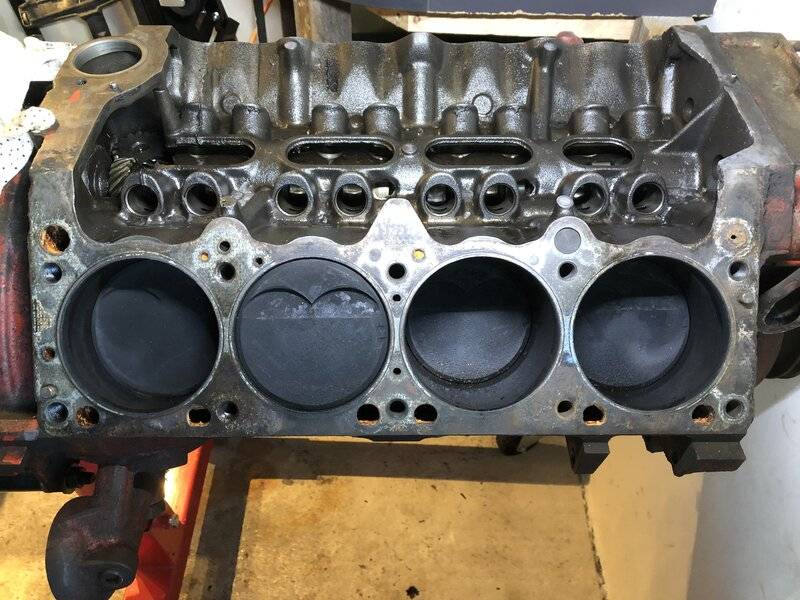

I am rebuilding my 340 and found a crack on each side of the block. The area looks quite strange to me since I could not find any pic on the internet where another block looks like mine. It looks a bit like some sort of plug but I am sure it is not. Can anyone explain what it is and how serious the crack in this area really is? Is the oil galley behind it or a water jacket?

Data:

LA 340

Casting Number 2760930-340-4

Built 6/22/67 (nightshift)

Engine was running before tear down, no smoke or other indicator for burned oil or water. No noticeable amount of oil in water (but a huge amount of rust in water channels and jacket)

Thanks a lot for your help!

Chris

I am rebuilding my 340 and found a crack on each side of the block. The area looks quite strange to me since I could not find any pic on the internet where another block looks like mine. It looks a bit like some sort of plug but I am sure it is not. Can anyone explain what it is and how serious the crack in this area really is? Is the oil galley behind it or a water jacket?

Data:

LA 340

Casting Number 2760930-340-4

Built 6/22/67 (nightshift)

Engine was running before tear down, no smoke or other indicator for burned oil or water. No noticeable amount of oil in water (but a huge amount of rust in water channels and jacket)

Thanks a lot for your help!

Chris